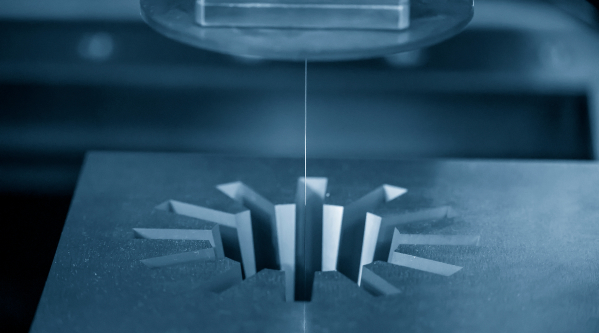

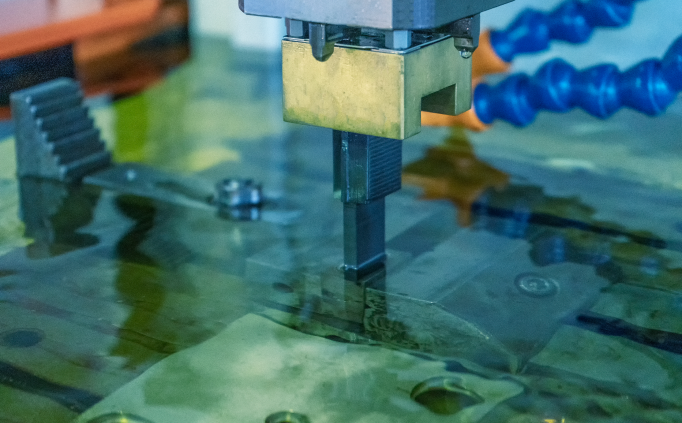

Fictiv offers two types of Electrical Discharge Machining (EDM) processes, which are useful for cutting deep pockets and complex features such as gears and holes with a keyway. EDM is also a non-contact machining method and does not exert cutting forces on the part, therefore it works particularly well for delicate structures.

- Home

- About Us

- Blog

- Capabilities

Sub-Processes

Plastic Materials

Processes Available

Post Processing

- Contact Us