- Home

- About Us

- Blog

- Capabilities

Sub-Processes

Plastic Materials

Processes Available

Post Processing

- Contact Us

| Processes | Lead Time | Colors | Tolerance | Price | Applications | Grades |

|---|---|---|---|---|---|---|

| CNC Mill CNC Lathe | As fast as 3 days | Opaque beige | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium | $$$ | Metal-alternative for high-stress applications | Standard PEEK, 30% Glass Filled |

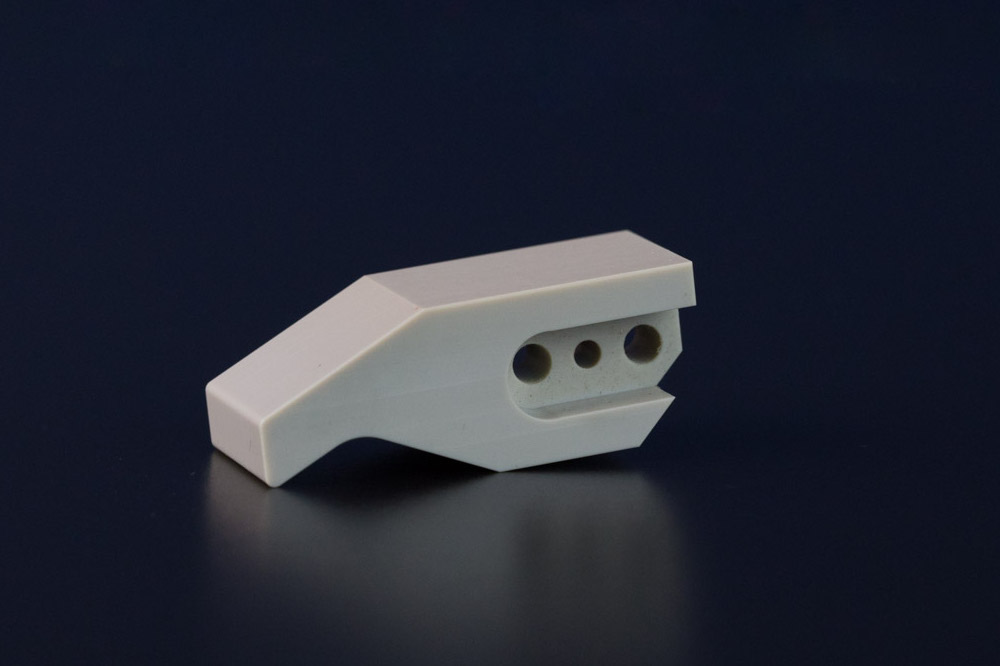

In high-stress/high-temperature applications, PEEK is a great lightweight substitute for most soft metals. Additionally, PEEK is resistant to moisture, wear, and chemicals.

Glass-filled PEEK is a high performance plastic with excellent rigidity, strength and toughness. The addition of glass fibers enhances its ability to maintain dimensional stability even in harsh thermal and chemical environments. This material is often used in the following industries: aircraft, automotive, medical, chemical, semiconductor and microwave.

PEEK

Yield Strength (tensile) | Elongation at Break | Hardness | Density | Maximum Temp | McMaster Part Number |

|---|---|---|---|---|---|

14,000 psi | 20% | Rockwell R125 | 0.047 lbs / cu. in. | 480° F | 8504K811 |

PEEK (30% Glass Filled)

Yield Strength (tensile) | Elongation at Break | Hardness | Density | Maximum Temp | McMaster Part Number |

|---|---|---|---|---|---|

14,000 psi | 20% | Rockwell R125 | 0.047 lbs / cu. in. | 480° F | 8504K811 |

PEEK comes in an opaque beige color and can be machined to a variety of surface finishes.

Max Part Size | Min End Mill Size | Min Drill Size | Min Wall Thickness | Undercuts | Radii : Depth |

|---|---|---|---|---|---|

| 1200 x 500 x 152 mm [x, y, z] (mill) 152 x 394 mm [d, l] (lathe) | 0.8mm (0.03 in) | 0.5mm (0.02 in) | 0.5 mm | Square profile, full radius, dovetail profiles | Depth must not exceed 12x drill bit diameter. For end mills, depth must not exceed 10x tool diameter. |

Cost Saving Tip

To reduce costs, limit the number of part setups, the number of inspection dimensions or tight tolerances, and deep pockets with small radii.

Visit our CNC Machining Services Page

ABS plastic is a low-cost engineering plastic, widely used for pre-injection molding prototypes. CNC machined ABS is a great option for production-like parts, where detail and mechanical properties are important.

Depending on the desired outcome for the project, ABS plastic can either be cut or engraved using CNC milling.

ABS plastic is an excellent choice for general purpose prototyping, pre-molding prototypes, parts that will receive impact and require toughness, or when low cost is desired.

CNC (Computer Numerical Control) machining is an automated, subtractive manufacturing process where a CNC machine is controlled with a set of commands that, when followed, will produce a part. CNC operators create….

example dowel pin interference fit table