- Home

- About Us

- Blog

- Capabilities

Sub-Processes

Plastic Materials

Processes Available

Post Processing

- Contact Us

| Processes | Lead Time | Finishing Options | Tolerance |

|---|---|---|---|

| CNC Mill CNC Lathe | As fast as 5 days | Available as-machined | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

Chemical-Resistant PVC (Polyvinyl Chloride) is a great choice for designs requiring electrical insulation. Chemical-Resistant PVC also offers terrific resistance to alkalies and acids, which makes it the ideal choice for applications related to chemical-processing and tank/valve components.

Chemical-Resistant PVC

| Processes | Lead Time | Finishing Options | Tolerance |

|---|---|---|---|

| CNC Mill CNC Lathe | As fast as 5 days | Available as-machined | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium |

ABS has a somewhat matte finish (think lego bricks) and can be painted. Certain faces may appear more shiny depending on their geometry and how they’re machined. If painting ABS parts, finish will be dependant of the choice of paint.

Min Wall Thickness | Min End Mill Size | Min Drill Size | Max Part Size | Undercuts | Radii : Depth |

|---|---|---|---|---|---|

0.5 mm (0.02 in) | 0.8 mm (0.03 in) | 0.5 mm (0.02 in) | 1200 x 500 x 152 mm [x,y,z] (mill) 152 x 394 mm [d,h] (lathe) | Square profile, full radius, dovetail profiles | Depth must not exceed 12x drill bit diameter. For end mills, depth must not exceed 10x tool diameter. |

Cost Saving Tip

To reduce costs, limit the number of part setups, the number of inspection dimensions or tight tolerances, and deep pockets with small radii.

Visit our CNC Machining Services Page

CNC (Computer Numerical Control) machining is an automated, subtractive manufacturing process where a CNC machine is controlled with a set of commands that, when followed, will produce a part. CNC operators create….

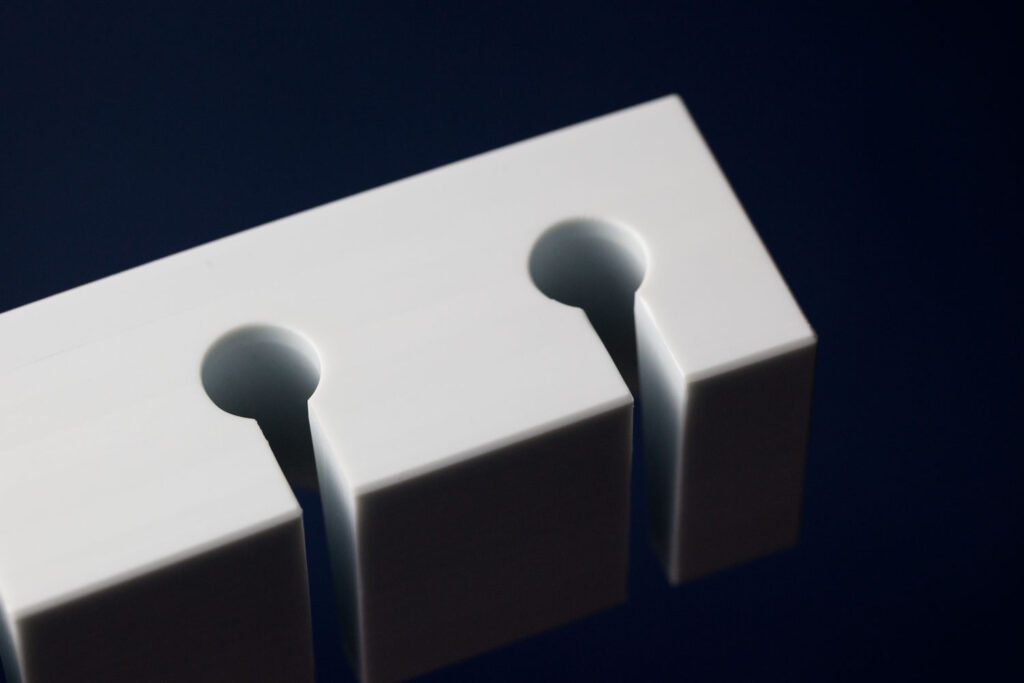

example dowel pin interference fit table