- Home

- About Us

- Blog

- Capabilities

Sub-Processes

Plastic Materials

Processes Available

Post Processing

- Contact Us

| Processes | Lead Time | Tolerance | Price | Applications | Alloys | Finishing Options |

|---|---|---|---|---|---|---|

| CNC Mill CNC Lathe | As fast as 3 days | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium | $$ | Light & economic, used from prototyping to production | 6061-T6, 7075-T6, 7050, 2024, 5052, 6063, MIC6 | Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing. |

Aluminum is one of the most commonly used metals in the world because of its excellent strength-to-weight ratio, low cost, and recyclability. Fictiv offers multiple aluminum alloys.

Our standard alloy on platform is 6061, a versatile and easy-to-machine metal. It is corrosion-resistant, non-magnetic, and heat treatable.

7075 Aluminum is a hard, high strength alternative to 6061 Aluminum . It is often used for parts in high-stress applications, and is also corrosion-resistant, non-magnetic and heat treatable.

7050 Aluminum can be used instead of 7075 when high stress corrosion resistance is necessary (ie. bulkheads and fuselage frames). It is heat treatable and non-magnetic.

2024 Aluminum is not as strong as 7075 Aluminum but is commonly used when a high strength-to-weight ratio is required. It is heat treatable and non-magnetic.

5052 Aluminum is the easiest aluminum to weld and is exceptionally corrosion resistant against salt spray and salt water. It is easy to form, heat treatable, and non-magnetic.

6063 Aluminum is more corrosion resistant and formable than 6061 Aluminum. It is not ideal for high strength applications, but can be used for exterior railings and decorative trim. It is heat treatable and non-magnetic.

Also known as jig plate or cast tool, MIC6 is a cast aluminum alloy that is great for tight tolerance applications due to it being stress-relieved. It is most commonly used in precision machine tables and tooling. MIC6 is non-magnetic and not heat treatable.

Zamak 3 (Zinc)

Yield Strength (tensile) | Elongation at Break | Hardness | Density |

|---|---|---|---|

| 30,000 PSI | 10% | Brinell 82 | 6.6 g/cm^3 0.24lb / in^3 |

Untreated aluminum generally has a dull silver/grey finish which varies depending on the roughness of the surface.

Many consumer products made with aluminum are anodized, most notably the MacBook Pro. Anodization allows the introduction of a variety of color options and adds a consistent shine across the entire part.

Aluminum can also be media-blasted, sanded, and hand-polished to achieve a multitude of surface finishes. Alodine is often used as an alternative protective coating to anodize on aluminum parts, and can be clear or gold in color.

Min Wall Thickness | Min End Mill Size | Min Drill Size | Max Part Size | Undercuts | Radii : Depth |

|---|---|---|---|---|---|

0.5 mm | 0.8 mm (0.03 in) | 0.5 mm (0.02 in) | 1200 x 500 x 152 mm [x,y,z] (mill) 152 x 394 mm [d,h] (lathe) | Square profile, full radius, dovetail profiles | Depth must not exceed 12x drill bit diameter. For end mills, depth must not exceed 10x tool diameter. |

Cost Saving Tip

To reduce costs, limit the number of part setups, the number of inspection dimensions or tight tolerances, and deep pockets with small radii. If surface finish is not a concern, you may design your part to be made from the closest stock thickness, specified in a drawing.

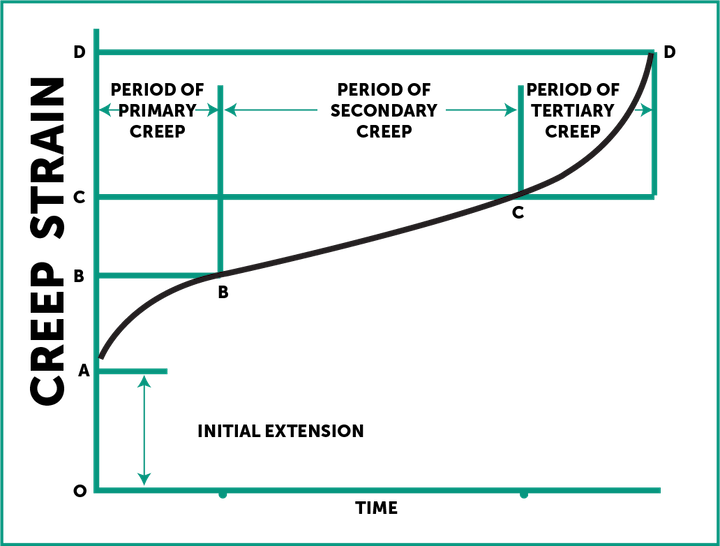

In mechanical engineering, creep is a metallurgical phenomenon where a metal slowly deforms due to prolonged exposure to stress below its yield strength. Read on to learn more about creep and how it works, then see some visual creep depictions and examples. What is Mechanical Creep? In Engineering Fundamentals Refresh: Strength vs. Stiffness vs. Hardness, […]

CNC (Computer Numerical Control) machining is an automated, subtractive manufacturing process where a CNC machine is controlled with a set of commands that, when followed, will produce a part. CNC operators create these commands through a process called CNC programming. This article describes CNC programming and the different types of CNC programming methods. What Is […]