Are you tired of the same old milling and turning services that promise precision but deliver mediocrity? Look no further! With our CNC Milling Turning Service, you can expect nothing less than perfection with a side of efficiency.

Our team of skilled technicians will handle your project with the utmost care and attention to detail, ensuring that every piece comes out exactly as planned. So why settle for anything less when you can have precision and efficiency in one package? Get ready to experience the future of machining with our CNC Milling Turning Service. Buckle up, because it’s going to be a wild ride!

What is CNC Milling Turning and how does it work?

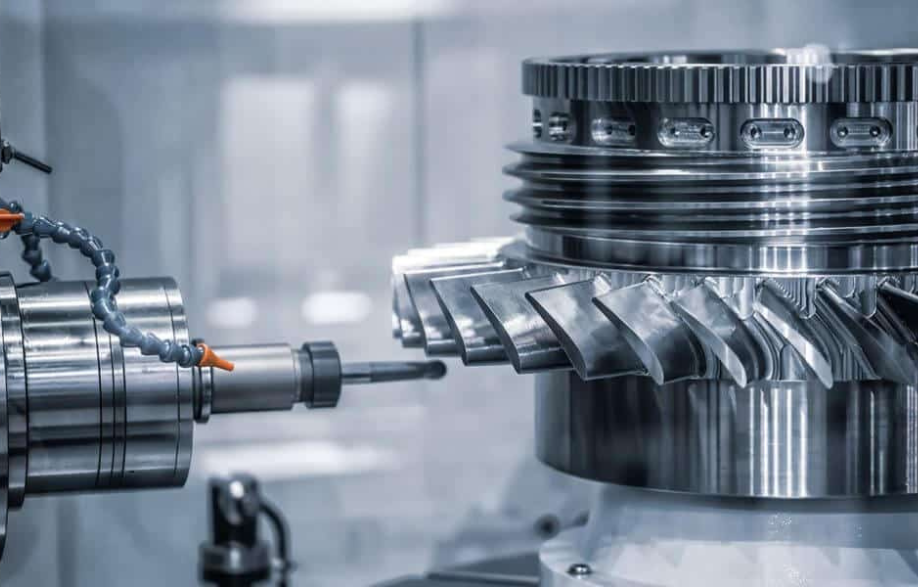

CNC Milling turning is a versatile machining process commonly used in the manufacturing industry. It combines two different operations, milling and turning, into a single automated process.

Milling involves removing material from a workpiece using rotary cutters to create complex shapes and features. This is done by moving the cutting tool against the workpiece in different directions.

Turning, on the other hand, involves rotating the workpiece while a cutting tool removes material to create cylindrical shapes. The cutting tool moves parallel to the axis of rotation to shape the workpiece accordingly.

Benefits of Ssing CNC Milling Turning Service

There are several benefits to using CNC milling turning services in the manufacturing industry.

Firstly, it allows for high precision and accuracy in the machining process. The computer-controlled automation ensures consistent and precise cuts, resulting in parts that meet strict tolerances.

Secondly, CNC milling turning enables the production of complex shapes and features that would be difficult or time-consuming to achieve manually. This versatility makes it ideal for creating intricate components or prototypes.

Additionally, CNC milling turning offers increased efficiency and productivity. The automated process allows for continuous operation without the need for constant manual intervention, reducing labor costs and increasing throughput.

Precision and Accuracy in Machining with CNC Milling Turning

CNC milling turning is renowned for its precision and accuracy in the machining process. With computer-controlled automation, the cutting tool follows a pre-programmed path with utmost consistency. This ensures that each cut is executed with meticulous precision, resulting in parts that adhere to strict tolerances.

The combination of milling and turning capabilities further enhances the precision of CNC machining. Milling allows for the creation of intricate shapes and features by removing material from the workpiece with rotary cutters. Turning, on the other hand, enables the production of cylindrical shapes by rotating the workpiece while a cutting tool removes material parallel to its axis. By combining these two processes, CNC milling turning offers unmatched precision and accuracy in the manufacturing industry.

Factors to Consider when Choosing a CNC Milling Turning Service P provider

When choosing a CNC milling turning service provider, there are several factors to consider. Firstly, it is crucial to assess the provider’s expertise and experience in the field. Look for a company that has specialized knowledge and a proven track record in CNC machining.

Secondly, consider the capabilities and technologies offered by the service provider. Ensure that they have state-of-the-art CNC machines and software to handle your specific machining needs. This includes assessing their ability to produce complex shapes, work with various materials, and meet strict tolerances.

Tips for Maximizing the Benefits of CNC Milling Turning Service

Here are some tips to maximize the benefits of CNC milling turning service:

- Clearly communicate your requirements: Provide detailed specifications and drawings to ensure that the service provider understands your project’s unique needs. The clarity in communication will help avoid misunderstandings and ensure accurate results.

- Optimize your design for CNC machining: Work closely with the service provider to optimize your design for CNC machining. By considering factors such as tool access, material selection, and part orientation, you can enhance the efficiency and accuracy of the machining process.

- Test prototypes before full-scale production: Before committing to large-scale production, it is recommended to test prototypes. This allows you to identify any potential issues or areas for improvement before investing in mass production. Testing prototypes also gives you the opportunity to make adjustments and refine your design without incurring significant costs.

- Regularly communicate and collaborate with the service provider: Maintain open lines of communication with the CNC milling turning service provider throughout the entire process. This ensures that any questions or concerns can be addressed promptly, and any necessary adjustments can be made in a timely manner.

- Monitor quality control: Keep a close eye on the quality of the machined parts during production. Regular inspection and quality control checks will help identify any deviations or defects early on, allowing for quick corrective measures to be taken.

- Explore additional finishing options: CNC milling turning services can provide a wide range of finishing options, such as polishing, anodizing, or painting. Consider these additional finishes to enhance the appearance and functionality of your parts.

- Evaluate cost-effectiveness: While CNC milling turning services offer numerous benefits, it is important to evaluate the cost-effectiveness of the process. Compare quotes from multiple service providers and consider factors such as lead times, quality, and customer reviews to make an informed decision. Remember that the cheapest option might not always be the best, as quality and reliability should also be taken into account.

- Plan for scalability: If your project has the potential to grow or expand in the future, it’s important to consider scalability during the CNC milling turning process. Discuss this with your service provider and ensure that they have the capability to handle larger production volumes if needed.

Conclusions

Maintaining open lines of communication with your CNC milling turning service provider is crucial for a successful project. By addressing any questions or concerns promptly, you can ensure that the process runs smoothly and any necessary adjustments are made in a timely manner.

Monitoring quality control throughout production is also essential. Regular inspections and quality control checks will help identify any deviations or defects early on, allowing for quick corrective measures to be taken.