Gears are everywhere, driving our cars, ticking in our watches, and powering machines. But have you ever wondered how these intricate pieces come to life? Enter the gear hobbing machine, a master at crafting perfect gear profiles. Using a special tool called a “hob,” it transforms plain metal into gears with precision teeth. Understand the magic behind this machine and unveil the secrets of how a gear hobbing machine works its wonders!

What is gear hobbing machine?

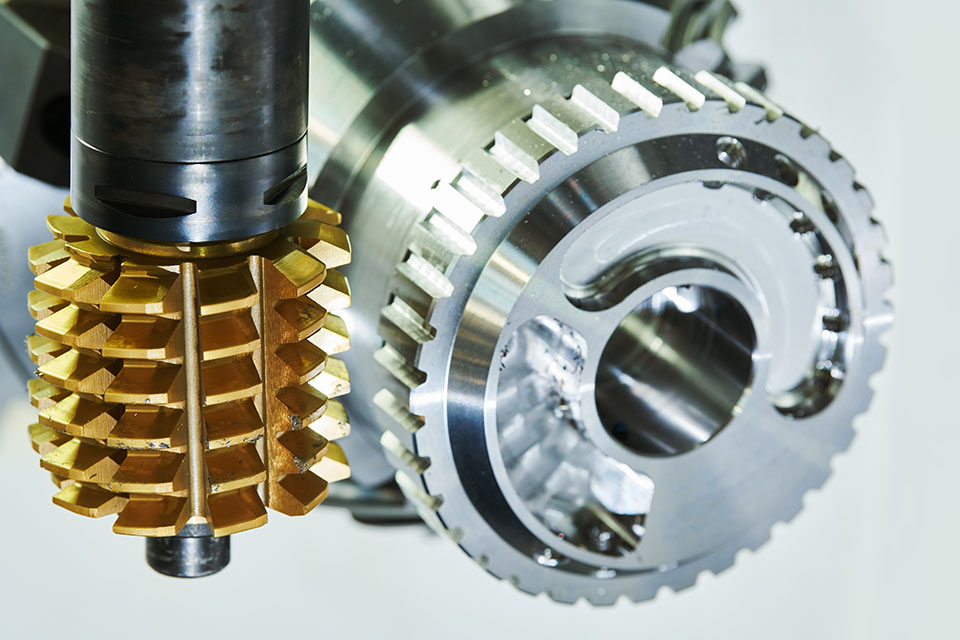

A gear hobbing machine is a special tool for making gears. It carves out the shape of gear teeth with precision. A rotating cutter, called a hob, interacts with the gear blank. As both rotate, the hob cuts the gear’s profile. This method ensures accurate and consistent teeth shapes. Gear hobbing machines are crucial in industries that need gears, like automotive and machinery. They offer a fast and efficient way to produce high-quality gears.

How gear hobbing machine work?

Gears play a central role in countless mechanisms, from wristwatches to massive industrial machines. Crafting these gears with precision is paramount, and that’s where the gear hobbing machine shines. But how does this wonderful machine create such detailed and intricate gear profiles?

Step 1: Understanding the Main Components

Before we understand the process, let’s identify the main parts of a gear hobbing machine.

Hob: This is the star player. It’s a cylindrical tool with helical cutting teeth. It looks a bit like a screw or worm gear.

Gear Blank: This is the piece of metal that will become our gear. It starts as a flat, round piece.

Indexing Mechanism: This ensures that the gear blank rotates at the correct speed, relative to the hob.

Step 2: Getting Started

To begin, we secure the gear blank in place. The hob positions itself at the start point. Think of it like placing a pen on paper before you start drawing. The distance between the hob and gear blank determines the depth of the cut.

Step 3: The Cutting Motion

Now, things start moving! The hob rotates, and so does the gear blank. As they both turn, the hob’s teeth begin to bite into the blank’s surface. The helical design of the hob allows for continuous cutting. This motion creates the valleys between gear teeth, known as “gaps” or “spaces”. The raised portions become the gear’s teeth.

Step 4: Progressing the Cut

As the machine runs, the hob gradually moves sideways across the gear blank’s width. This ensures that the entire length of each gear tooth gets shaped. The machine controls this movement, ensuring consistency and precision.

Step 5: Indexing and Synchronization

This step is vital. The gear blank must rotate at a speed that matches the hob’s movement. This synchronization ensures each tooth forms correctly. The indexing mechanism helps with this. It controls the gear blank’s rotation, ensuring perfect spacing between teeth.

Step 6: Finalizing the Gear

Once the hob has moved across the entire width of the gear blank, the process is nearly complete. The gear now has a full set of accurately spaced and formed teeth. After removing the newly formed gear, it often undergoes additional treatments or inspections to ensure quality.

Why Gear Hobbing Stands Out

Gear hobbing offers several benefits that make it a preferred method for gear creation:

Efficiency: The continuous cutting action of the hob means faster production. One can produce large batches of gears in less time.

Precision: The machine’s controlled movements guarantee consistent and precise gear profiles. This precision ensures the gears mesh perfectly with others.

Flexibility: By changing the hob, manufacturers can create a wide range of gear profiles. This adaptability is great for catering to different industry needs.

Applications of Gear Hobbing

The world of machinery owes much to gear hobbing. Here are some areas where its influence is profound:

Automotive: From transmissions to differentials, cars rely heavily on gears. Quality is paramount, and gear hobbing delivers.

Watches and Clocks: Precision is vital in timekeeping. The tiny gears inside your watch likely owe their existence to a gear hobbing machine.

Industrial Machinery: Many heavy machines, from milling equipment to elevators, depend on robust gears to function.

Final Words

Gear hobbing is a marvel in the world of manufacturing. Using a rotating tool to carve out the intricate profiles of gear teeth, ensures machines everywhere can run smoothly and efficiently. Next time you see gears in action, remember the precision and care that went into their creation. The gear hobbing machine, with its meticulous process, truly shapes the world in more ways than one!

Common Questions About Gear Hobbing

Can all gears be made using gear hobbing?

While gear hobbing is versatile, it primarily suits spur and helical gears. For more complex gear types, like bevel or worm gears, other methods might be better.

How does one choose the right hob?

The hob’s profile determines the gear’s final shape. So, using a different hob will yield a different gear tooth profile. Manufacturers select hobs based on desired gear specifications.

Does the gear require finishing after hobbing?

In many cases, yes. Although hobbing ensures precise shaping, additional finishing processes can enhance the gear’s surface finish or accuracy.