CNC machining technology stands for “Computer Numerical Control.” It’s a process where computers guide machinery to create parts. Think of it like a robot sculptor! You give it a design on a computer, and the machine brings it to life. It cuts, shapes, and drills materials like metal or wood. The result? Precise and consistent pieces every time. It’s super helpful in industries like car manufacturing or aerospace. With CNC, creating complex designs becomes much easier.

The Different Types of CNC Machines

CNC Mills

CNC mills are versatile and can handle a variety of tasks. They function by moving the workpiece in multiple directions against a rotating tool. Mills can operate in three, four, or even five axes, providing great precision. They’re often used in industries ranging from automotive to aerospace.

CNC Lathes

Lathes specialize in producing cylindrical parts. The workpiece turns on a spindle while the cutting tool, which remains stationary, shapes the piece. This machine is excellent for producing items like screws, metal candle holders, and even musical instruments.

CNC Routers

CNC routers are cousins to the milling machines but primarily target wood, foam, and plastics. With their high-speed operation, they efficiently carve designs into these materials. From creating intricate patterns on wooden doors to shaping foam for packaging, routers are versatile.

CNC Plasma Cutters

A plasma cutter is a dream for metalworkers. It cuts by sending an electric arc through a gas (often compressed air), turning some of the gas into plasma. This hot plasma melts the metal and blows the molten metal away, cutting.

CNC Laser Cutters

Precision is the game for laser cutters. They focus a laser beam to melt, burn, or vaporize materials, offering high accuracy. They’re ideal for cutting thin materials, and you’ll often find them in industries requiring detailed engraving.

CNC Water Jet Cutters

Using a mixture of water and an abrasive substance, these machines exert powerful pressure to make cuts. The beauty of water jet cutters is they don’t produce heat, making them perfect for materials that can’t tolerate high temperatures.

3D Printers

These are revolutionizing industries. 3D printers add material, typically layer by layer, to create objects. From plastic toys to medical prosthetics, they’ve opened doors to endless possibilities.

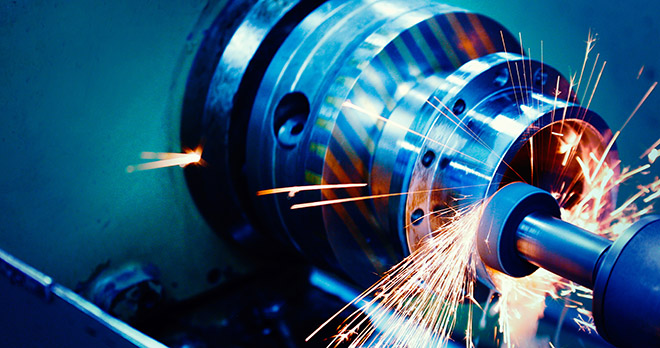

CNC Electric Discharge Machines (EDM)

EDM is a bit of a marvel. It works by creating sparks between an electrode and a workpiece. These sparks produce intense heat, melting tiny bits of the metal piece at a time. It’s a controlled process, and the result is incredibly precise.

What Can a CNC Machine Do?

Ever wondered what magic CNC machines can create? Let’s unravel that mystery together!

Precision Cutting

CNC machines follow exact computer-driven directions. This ensures each product replicates the digital design with high accuracy, leading to consistent, high-quality outputs with minimal discrepancies.

Creating Car Parts

Vehicles rely on exact parts for safety and efficiency. CNC machines produce complex pieces with tight tolerances. From gearshifts to intricate engine components, CNC ensures our cars drive reliably.

Musical Instruments

Precision is essential for musical clarity. CNC machines carve guitar bodies to produce specific tones or shape wind instrument components for perfect pitch, making each note just right.

Medical Equipment

In the medical world, a millimeter can make a difference. CNC machines create detailed surgical instruments, custom prosthetics, and implants. These tools aid in precise surgeries and patient recovery.

Art and Jewelry

Artists use CNC machines for intricate designs. They help carve detailed pendants or sculpt metal into delicate earrings. For larger art pieces, CNC aids in replicating precise patterns on materials like stone.

Home Decor

Custom furniture, ornate mirrors, or unique lighting fixtures can be CNC-crafted. The machines ensure consistency in designs, whether it’s a set of chairs or decorative panels for doors.

Electronics

Modern gadgets rely on miniature, precise components. CNC machines assist in creating tiny connectors, heat sinks, or chip housings, ensuring electronic devices function flawlessly.

Aviation Parts

In aviation, component accuracy is non-negotiable. CNC machines produce parts like turbine blades or cockpit instruments. This precision ensures aircrafts operate safely and efficiently.

Kitchenware

Ever marveled at a beautifully designed cutlery set? CNC machines craft these, ensuring ergonomic designs and patterns that stand out, from spoons to stylish pots.

Boat Components

Boats need parts that withstand aquatic environments. CNC machines help craft corrosion-resistant parts, ensuring long-lasting performance while sailing or cruising.

Engravings and Markings

Custom engravings make items memorable. CNC machines engrave intricate patterns or texts on metals, woods, or plastics, adding a personalized touch to gifts or memorabilia.

Prototyping

Before mass-producing, prototypes are essential. CNC machines rapidly produce these prototypes, allowing companies to test, refine, and perfect their designs quickly.

3D Objects

CNC isn’t just about flat designs. Machines can carve out three-dimensional objects, creating layered artistic pieces or functional items from single material blocks.

Toy Manufacturing

Toys need to be safe and durable. CNC machines craft smooth-edged wooden toys or detailed plastic models, ensuring safe playtime for kids.

Building Supplies

Construction demands reliable materials. CNC machines produce custom bricks with interlocking designs or window frames that fit perfectly, ensuring strong, durable structures.

Sports Equipment

For athletes, equipment quality can impact performance. CNC machines shape cricket bats for optimum balance or mold golf club heads for precise shots.

Glasses and Frames

Comfort and style matter for eyewear. CNC machines design frames that not only look good but also fit comfortably, ensuring users have optimal vision with flair.

Custom Gears and Tools

Specific tasks demand unique tools. CNC machines design these tailored tools, whether it’s a gear for a specific machine or a custom wrench for a unique bolt.

CNC machines merge computer precision with real-world craftsmanship. They shape, mold, carve, and engrave, touching almost every industry and product we encounter. Their blend of accuracy and versatility makes them indispensable in today’s world.

How do CNC machines Reshape Modern Manufacturing?

CNC machines have truly revolutionized modern manufacturing. Let’s explore how they’ve made such a big splash.

Boosted Efficiency

CNC machines work fast, day or night. They can churn out products quicker than manual labor, increasing production rates significantly.

Enhanced Precision

Accuracy is a CNC machine’s middle name. They follow digital designs to the dot, ensuring every item matches the blueprint perfectly.

Reduced Waste

Mistakes can be costly in manufacturing. CNC machines minimize errors, which means fewer materials go to waste, saving money and resources.

Flexibility in Design

Change is easy with CNC. If you want a new design, just update the software. No need to retrain workers or adjust manual tools.

Safer Work Environments

Since CNC machines handle complex tasks, workers face fewer risks. They aren’t directly dealing with sharp tools or heavy materials.

Consistent Quality

Every item a CNC machine produces is a near-perfect replica of the last. This consistency ensures brands maintain their reputation for quality.

Skilled Labor Shift

CNC machines have changed the workforce landscape. Now, factories need more tech-savvy operators than traditional laborers.

Cost Savings

While the initial investment might be high, CNC machines pay off. They reduce labor costs, waste less material, and minimize errors.

On-Demand Production

Need a small batch of items? No problem. CNC machines can switch between jobs quickly, suiting both mass and custom production.

Sustainability

With less waste and more efficient energy use, CNC machines support eco-friendly manufacturing. They align with the green goals of many modern companies.

FAQs

What is CNC machining technology?

CNC stands for Computer Numerical Control. It’s a process where computers control machine tools to produce precise parts from digital designs.

How does CNC machining differ from traditional manufacturing?

In traditional manufacturing, operators manually control tools. With CNC machining, computers guide the tools, ensuring higher precision and consistent quality.