Introduction

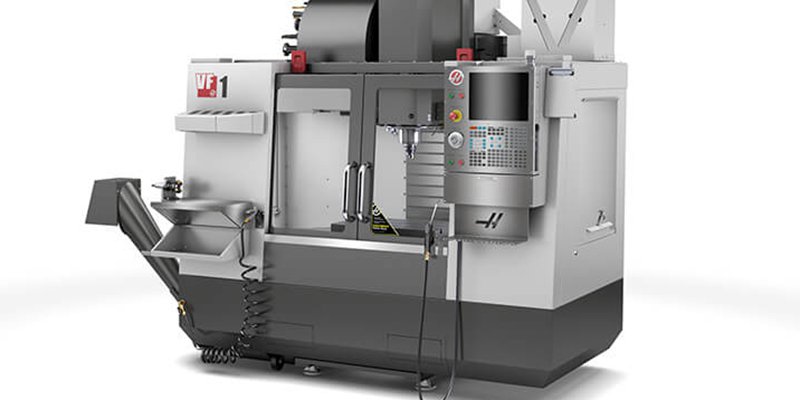

CNC machines have become genuine miracles in the fascinating world of current production, raising the bar for production efficacy and accuracy to a completely novel level. Imagine them as super machines that can create things with incredible accuracy! These Computer Numerical Control (CNC) machines are like the wizards of the workshop, making sure everything is just perfect. Big companies, including the giants in the car industry, and smaller workshops alike have welcomed these machines into their daily operations. They’ve become an essential tool, transforming the way things are made, from large-scale automotive components to delicate creations in smaller workshops. The sector for production is becoming more vibrant and productive than ever because of the increasing use of CNC machines, which are a radical change for constructing and producing.

What companies use CNC machines?

How do automotive companies use CNC machines?

Car makers use special machines called CNC machines to make cars better and faster. These machines are like super-precise wizards that help with different steps in creating cars. First, they help make models and designs really accurately. Then, they’re like superhero tools for cutting and shaping metal parts for engines and other important car stuff. They even make plastic parts for the inside and outside of cars. These machines are cool because they can be changed to make special and unique car parts. And guess what? They also help make sure the parts are just right and don’t waste materials, which is good for making cars without mistakes. So, these CNC machines are like heroes behind the scenes, making our cars awesome!

Aviation pioneers are soaring high.

Aviation pioneers rely on CNC (computer numerical control) machines to revolutionize aircraft design and manufacturing. These high-tech machines play a crucial role in creating precise prototypes and intricate designs for various aircraft components, ensuring accuracy in the early stages of aircraft development. CNC machines are instrumental in the precision machining of aerospace materials, crafting intricate engine components, and producing lightweight yet sturdy structures for aircraft interiors through sheet metal fabrication. They contribute to the production of specialized tools and dies, facilitating the creation of components that meet the stringent standards required for aircraft manufacturing. Additionally, CNC machines support aircraft modification and retrofitting, allowing pioneers to customize and enhance the performance of existing aircraft models. From manufacturing composite materials to ensuring quality assurance and enabling rapid prototyping, these machines are indispensable tools driving innovation and progress in the dynamic field of aviation.

How do tech innovators use CNC machines?

In the world of creating cool tech stuff, innovators use special machines called CNC machines. These machines are like super-smart tools that help make new gadgets quickly. They’re great for creating models of new ideas and making parts for phones, laptops, and other cool devices. CNC machines can even build the outer covers of gadgets to make them look sleek and cool. Some of these machines can do 3D printing, making things layer by layer, which is awesome for creating special shapes and prototypes. Innovators also use CNC machines to make special tools and customize materials for their tech creations. It’s like having a high-tech workshop that can bring amazing tech ideas to life!

How do healthcare companies use CNC machines?

In the world of healthcare, CNC machines are like super-smart tools that help make important medical stuff. These machines are great at creating precise parts for things like surgical tools, implants, and even dental work. They’re like the artists behind prosthetics and customized implants, making sure everything fits just right for patients. CNC machines also help healthcare researchers try out new ideas quickly by creating prototypes. They’re handy in crafting equipment for labs and even play a role in making things like braces and rehab devices. These machines are like superheroes in healthcare, ensuring that everything is made with precision for the best results in patient care.

Customization in Furniture Manufacturing

Imagine CNC machines as super-smart tools in the world of making cool furniture. These machines are like magic sculptors, helping create unique designs and patterns on tables, cabinets, and other furniture pieces with super precision. They can even add personal touches like names or special logos. Whether it’s making a piece fit perfectly in your room or quickly testing out new ideas before making the real thing, CNC machines are like furniture superheroes, making sure every piece is just right for you.

how do the construction companies use CNC machines?

In the construction world, CNC machines are like superhero tools that bring precision and customization to the building process. These smart machines precisely cut and shape building materials like wood, steel, and concrete, ensuring that components like beams and panels are just the right size. They’re not just about the basics; CNC machines also help create custom architectural elements, decorative features, and even prefabricated building components. Whether it’s shaping concrete into specific forms, producing specialized construction tools, or contributing to the efficiency of steel fabrication, CNC machines play a crucial role. They’re like the architects’ assistants, making sure every detail is just as it should be in construction projects, from prototypes to the final building.

Frequently Asked Questions

What are the primary advantages of CNC machines?

CNC machines offer unparalleled precision, efficiency, and repeatability in manufacturing processes. They reduce human error, enhance production speed, and allow for complex designs.

How expensive are CNC machines for small businesses?

The cost of CNC machines varies, but there are affordable options suitable for small businesses. Factors such as machine type, capabilities, and brand influence the overall cost.

Can CNC machines be used for prototyping?

Absolutely. CNC machines are widely used for prototyping due to their ability to accurately reproduce intricate designs. They are crucial in the product development phase.

Are CNC machines difficult to operate?

While there is a learning curve, modern CNC machines often come with user-friendly interfaces. Training programs and manuals are available to facilitate smooth operation.

Find out more facts

Find out more facts about CNC machines in the best and easiest way on the website of Junying. Here, you will be comfortable learning more. And the special thing about Junying here is that you will find many more machines to learn about. So for more unknown facts, just visit the website.

Conclusion

In the ever-evolving landscape of manufacturing, CNC machines have become indispensable for companies aiming for precision and efficiency. From global giants to local artisans, the widespread adoption of CNC technology underscores its transformative impact. Understanding why companies use CNC machines reveals the diverse applications and pivotal role they play across industries.