China is a leading player in the rapidly evolving industrial sector, known for its high accuracy and productivity. This article will take you on a journey through the direct and impactful realm of CNC machining in China. Buckle up as we explore the intricacies of this fascinating industry without delving into the abyss of technical jargon.

Introduction

Welcome to the realm where precision meets innovation—CNC machining in China. It explores the many facets of China’s manufacturing sector, emphasizing the country’s leadership in sophisticated production.

The Rise of CNC Machining in China

China’s ascent in CNC machining China has been nothing short of spectacular. From traditional craftsmanship to embracing advanced technologies, the journey has been swift and transformative. Let’s delve into the factors propelling China to the forefront.

Understanding CNC

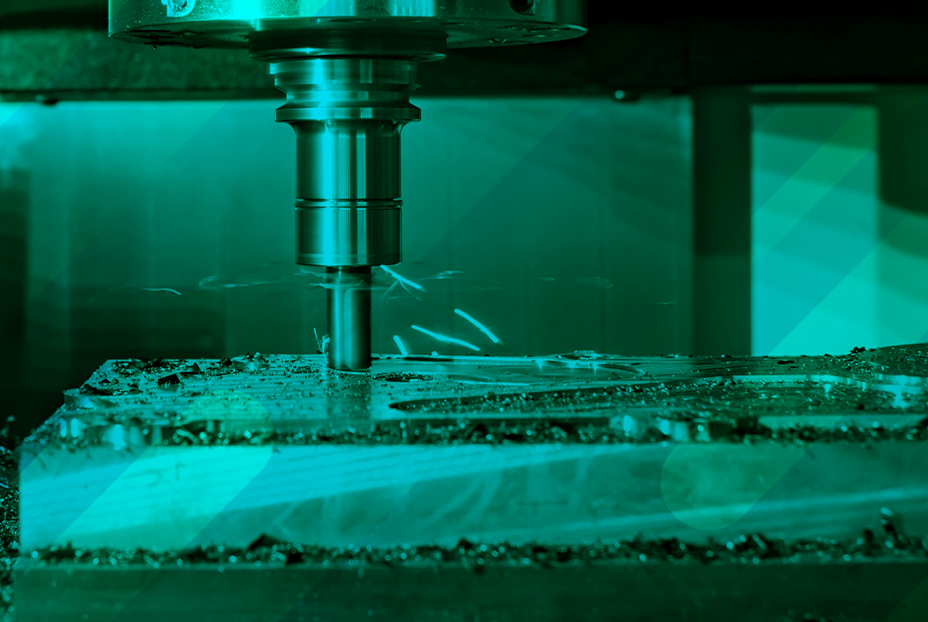

But first, what exactly is CNC? We’ll break down the technical walls and provide a simple, digestible overview of computer numerical control machining and its significance in the manufacturing landscape.

How CNC Works

Ever wondered how CNC achieves such impeccable precision? Join us in demystifying the magic behind each cut and carve as we break down the intricate process of CNC machining in China.

Cost Efficiency

In the competitive world of manufacturing, cost efficiency is key. see how CNC machining China provides a cost-effective solution without compromising on quality.

Quality Assurance

China’s commitment to quality goes beyond mere promises. Explore how the country has set high standards, ensuring that every product meets or exceeds expectations.

Navigating Challenges

No journey is without its challenges. We’ll navigate through common hurdles in Chinese CNC machining China, providing insights into how businesses can overcome them.

Future Trends

Several future trends are expected to shape the landscape of CNC machining, reflecting advancements in technology, sustainability, and efficiency.

CNC Applications in Various Industries

CNC machining isn’t confined to a single industry. CNC (Computer Numerical Control) machining plays a vital role in various industries, offering precision, efficiency, and versatility in manufacturing processes.

Choosing the Right One

Selecting the right partner is crucial for success. Gain valuable insights into the factors to consider when choosing a CNC machining partner in China.

Sustainability in CNC

In an era of environmental consciousness, see how CNC machining in China is adopting sustainable practices, contributing to a greener and cleaner future.

The materials used in CNC machining

Metals:

Aluminum, steel, brass, copper, titanium, and inconel are like super materials! They are strong, lightweight, and can resist things like rust. They are used to make things that need to be tough, look cool, and even stuff that goes inside our bodies because they are friendly to our bodies.

Plastics:

Imagine your favorite devices and how they can be squishy or see-through. That’s what plastics are like! Plastics, such as acrylic, nylon, polyethylene, polypropylene, and polycarbonate, can be clear like glass, tough like superhero armor, and are used to make things that don’t break easily.

Composites:

This is like mixing different abilities! Carbon Fiber Reinforced Polymers (CFRP), Fiberglass Reinforced Plastics (FRP), and Kevlar are special materials that combine strength and toughness. They help make things like super cool spaceships, cars, and even clothes that keep us safe.

Wood and wood composites:

Wood is like nature’s own building block! MDF is a strong and stable wood used for making models and cool woodworking projects. Plywood, made by sticking layers of wood together, is super strong and keeps things from wobbling.

Ceramics:

Think of ceramics as super fancy and strong pottery! Alumina is a metal with a hard shell, and zirconia is tough and resistant to wear and tear. They are used to make things that need to be really tough, like parts of machines.

Foam Materials:

Imagine a soft and bouncy cloud! Foam materials, like alumina and zirconia, are a bit like that, but they also have some super qualities. They’re used for different things, like making things soft, absorbing shocks, and even being super good at not letting electricity pass through.

Others:

Rubber and graphite are like flexible and cool sidekicks! Rubber is stretchy and is used in bouncy balls and even the soles of our shoes. Graphite is also good at sliding around and helping things move smoothly. They’re both pretty amazing in their own special ways!

FAQs

Is CNC machining only for large-scale production?

No, CNC machining is versatile and caters to both small and large-scale production needs.

How does Chinese CNC machining compare to other global options?

Chinese CNC machining excels in cost efficiency, precision, and advanced technology, making it a competitive choice globally.

Can I trust the quality of products from Chinese CNC manufacturers?

Absolutely. Chinese CNC manufacturers adhere to high-quality standards, ensuring reliable and top-notch products.

Are there language barriers when dealing with Chinese CNC manufacturers?

Many Chinese manufacturers have English-speaking teams, minimizing language barriers and ensuring smooth communication.

What steps can businesses take to ensure sustainability in CNC manufacturing?

Opt for CNC manufacturers in China actively adopting sustainable practices, such as recycling and energy-efficient processes.

Lets learn more

In this article, we’ve peeled back the layers of CNC machining in China, bringing you closer to the heart of this dynamic industry. But if you feel like you need more, you can visit the website of Junying. Here, on the website of Junying, you will find much more information about this so go on and visit. Whether you’re a business seeking efficiency or an enthusiast exploring the world of manufacturing, China’s extreme lead in CNC machining is a journey worth embarking on.

Conclusion

As we wrap up our exploration, the extreme lead to CNC machining in China becomes evident. Precision, technology, cost efficiency, and commitment to quality make China a powerhouse in the CNC world.