Introduction

Delve into the intricate world of precision manufacturing with our comprehensive guide on mastering the art of gear hobbing. The key to crafting gears with unparalleled accuracy lies in understanding how to use a gear hob effectively. however the level of skill with machining or lack of familiarity with gear production, this tutorial leads you around the entire method in stages. From the initial setup of the hobbing machine to the intricacies of selecting cutting parameters, we unravel the secrets behind achieving flawless gear profiles. Join us on this journey to empower yourself with the knowledge needed to elevate your gear manufacturing endeavors, from design precision to enhanced productivity. Let’s explore the nuances of hobbing gear together and unlock the potential for perfection in motion.

How to use a gear hob

Using a gear hob effectively involves a series of steps to ensure precision and quality in gear manufacturing. Here’s a general guide on how to use it:

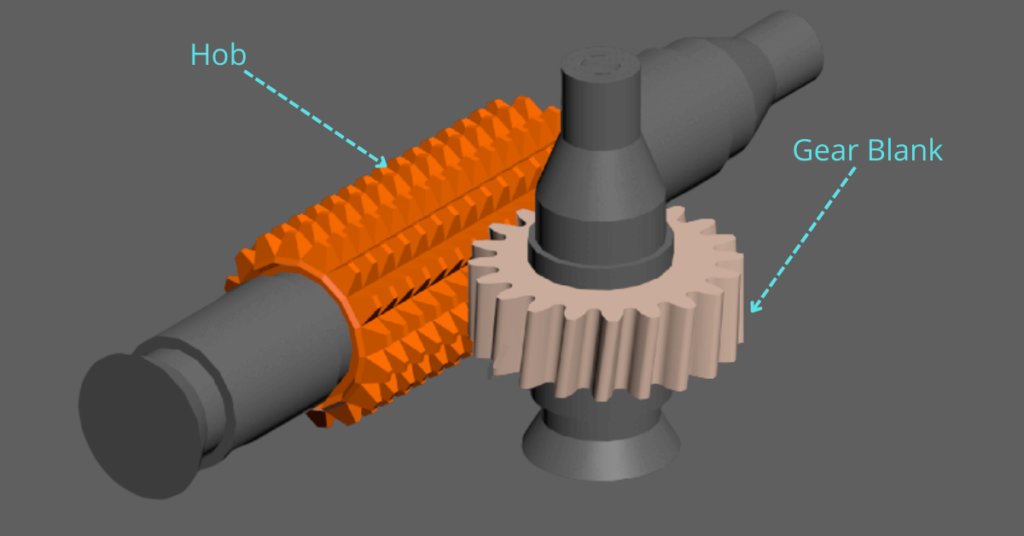

Set up the Hobbing Machine: Mount it securely onto the hobbing machine. Ensure proper alignment and fixturing to prevent any misalignment during the cutting process.

Select the workpiece: Choose a suitable gear blank based on the required gear specifications. The material and size of the workpiece should align with the gear design and intended application.

Machine Calibration: Calibrate the hobbing machine settings, including rotational speed, feed rate, and depth of cut. These parameters depend on factors such as material, gear type, and desired precision.

Secure the Workpiece: Securely mount the workpiece on the machine, ensuring it is centered and aligned with the hob. Proper fixation prevents any movement during the cutting process.

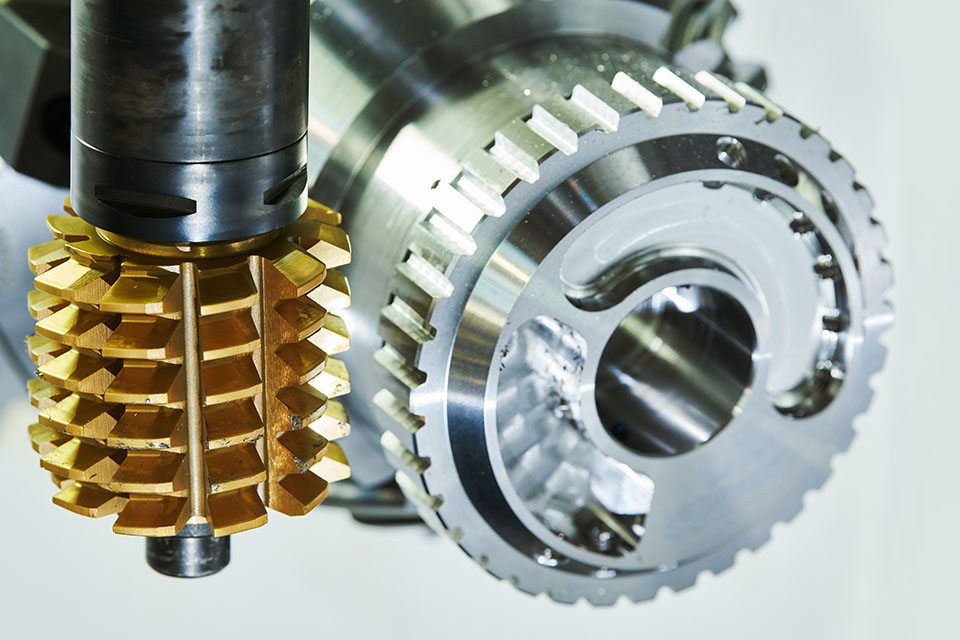

Engage the Hob: Gradually engage the gear hob with the rotating workpiece. The hob’s cutting edges will begin removing material from the gear blank, forming the gear teeth.

Monitor the Cutting Process: Continuously monitor the cutting process for any irregularities or issues. Adjust machine parameters if necessary to maintain consistent and accurate cutting.

Cooling and Lubrication: Implement a cooling and lubrication system to dissipate heat generated during cutting and reduce friction. This helps prolong the life of the gear hob and ensures a smoother machining process.

Inspect the gear teeth: Periodically inspect the gear teeth to ensure they meet the required specifications. Check for any defects, inaccuracies, or signs of wear on it.

Complete the Hobbing Process: Allow the machine to complete the hobbing process. Once finished, disengage the hob from the workpiece and carefully remove the machined gear.

Post-Machining Inspection: Inspect the finished gear for accuracy, tooth profile, and overall quality. If needed, make adjustments to the machine setup for subsequent machining processes.

Safety Measures you should follow

Staying safe during gear hobbing is really important, and there are some simple rules to follow. First, check out the manuals that come with the hobbing machine; they’re like your guides for the machines. Continue to keep cool and safe with safety equipment involving gloves, earplugs, and goggles. Verify that the machines are not aged or cracked by leaving a check on them. Let only trained folks use the machines, and make sure nobody gets too close when they’re working. When repairing a thing, use specialty grips to hold onto the components, and be ready with alternate solutions for when anything goes incorrect. Repair any old tools while keeping the devices cool and coated. Keep your workspace tidy so nobody trips, and wear ear protection if it gets noisy. Talk to each other and practice being safe; it makes everything run smoothly and keeps everyone out of harm’s way when using gear hobbing machines.

Find out more information about gear hob

The Junying website is like the go-to place if you want to learn cool stuff about gear hobbing. It’s super easy to use, and you’ll find lots of helpful things like easy guides, interesting articles, and pictures that make learning about gear hobbing fun for everyone. The website is all about being clear and right, and they’ve got all the cool info organized really well. From the basics to the super cool stuff, it’s all there! Likewise it’s basic to use the web page, which means you will not become confused while researching. If you want to know more about this, Junying’s website is the place to be!

FAQs

What safety precautions should I take when using a gear hob?

Ensure you wear appropriate personal protective equipment, follow machine safety guidelines, and implement proper machine setup and maintenance. Restrict access to authorized personnel only.

How do I set up a hobbing machine for this?

Properly mount it on the machine, secure the workpiece, and calibrate machine settings such as rotational speed, feed rate, and depth of cut according to the specifications.

What are the key cutting parameters to consider during gear hobbing?

Important cutting parameters include feed rate, depth of cut, and rotational speed. Adjust these parameters based on the material of the workpiece and the specific gear design.

How do I prevent overheating during the gear hobbing process?

Implement a cooling and lubrication system to dissipate heat generated during cutting. Ensure proper cooling fluids are used to maintain optimal operating temperatures.

What maintenance is required for it?

Regularly inspect it for wear and damage. Replace any worn-out tools promptly to maintain cutting precision and prevent accidents.

Can a single-gear hob be used for different types of gears?

In some cases, yes, but it depends on the versatility of the hob. It’s generally recommended to use a specific type of gear tailored to the gear being manufactured.

How do I troubleshoot common issues during this?

Monitor the cutting process for irregularities and adjust machine parameters accordingly. Address issues such as tool wear, improper setup, or material inconsistencies.

What post-machining checks should I perform on the finished gears?

Inspect the finished gears for accuracy, tooth profile, and overall quality. Make any necessary adjustments to the machine setup for subsequent machining processes.

Conclusion

Mastering how to use it is a gateway to unlocking endless possibilities in gear cutting. With the right knowledge and techniques, you can elevate your machining skills and achieve unparalleled precision. Gear up for success in the world of gear hobbing!