Gear hobbing is crucial for making gears precisely in many industries. It’s important in cars, planes, and machines. Gear hobbing shapes gear teeth carefully, so machines work smoothly. This article explains why gear hobbing matters in industries. It helps machines work better and last longer. Gear hobbing is a key technology for many machines.

Definition of Gear Hobbling

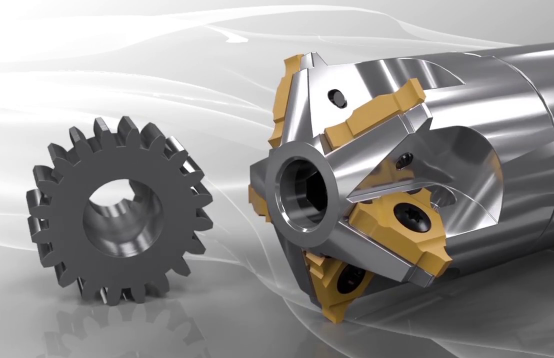

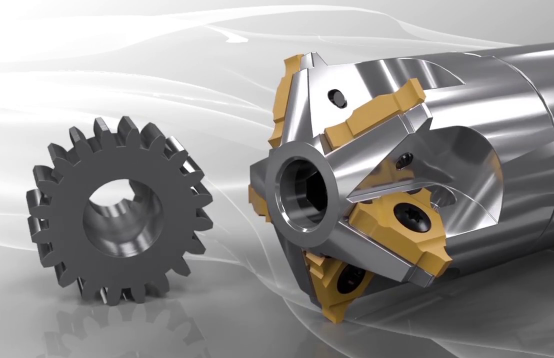

Gear hobbling is a precise machining technique vital in crafting gears for machinery. In simple terms, it’s like sculpting gears with a specially designed tool called a hob. This process ensures gears mesh seamlessly, enhancing overall machinery performance. Operating in an active mode, a hobbing machine cuts teeth into a gear blank, creating precise shapes and sizes. Transitioning from raw material to finely crafted gear, hobbling guarantees durability and efficiency. It’s a key player in the manufacturing game, optimizing gear production for various industries. Understanding gear hobbling is pivotal for those delving into the intricate world of machinery fabrication.

Purpose of Gear Hobbing

- Accuracy Gear Creation: Gear hobbing is primarily used to create gears with the highest level of accuracy. Manufacturers may ensure smooth and effective gear operation by utilizing a hobbing machine to precisely cut teeth into gear blanks.

- Improving Gear Performance: The performance characteristics of gears made via hobbing are outstanding. The teeth are machined precisely so that the gears mesh seamlessly, reducing wear and friction. This thereby improves the machinery’s overall lifetime and efficiency.

- Customization and Flexibility: Gear hobbing gives producers the ability to create a wide range of gears in terms of dimensions, forms, and tooth profiles. Meeting the various needs of various sectors and applications depends heavily on this customizability.

- Cost-Effectiveness: Gear hobbing is a cost-effective technique for mass-producing high-quality gears, even though it needs certain tools and knowledge. The hobbing method is a popular option among producers because of its efficiency, which eventually results in lower manufacturing costs.

- Applications Versatility: Gear hobbing occurs in many different industries, such as manufacturing, automotive, aerospace, and marine. Applications for gears made via hobbing are many and include anything from industrial machines to transmission systems.

- Consistency and Reliability: Gear hobbing offers several benefits, one of which is its capacity to manufacture gears that are consistently reliable and of high quality. The automated technique of hobbing guarantees consistency in tooth profiles and dimensions, which enhances the dependability of gear performance.

- Reduced Lead Times: Gear hobbing usually results in lower lead times as compared to conventional gear production techniques. The hobbing process’s efficiency enables producers to meet tight production deadlines without compromising on quality.

- Maintenance and Repair: Gear hobbing is a part of equipment maintenance and repair. To ensure smooth system integration and functionality, replacement gears can be precisely hobbed to match existing components.

Applications of gear hobbing in Various Industries

A flexible machining technique called gear hobbing is used in many different sectors and helps machinery run smoothly. Let us examine the critical roles that this precise method performs throughout several industries.

Automotive Industry

The foundation of transmission systems in the automobile industry is gear hobbing. It creates gears that smoothly coordinate to provide flawless gear changes. Gear hobbing improves the dependability and effectiveness of vehicles on the road, whether they be automobiles, trucks, or motorbikes.

Aerospace Sector

Aerospace demands precision, and creating gears for aircraft engines and navigation systems requires skillful gear hobbing. In the aerospace sector, hobbed gears are essential because their precision affects both the safety and functionality of machines.

Manufacturing and Machinery

In the industrial industry, gear hobbing is essential. Gears made by hobbing enable the efficient functioning of a variety of production processes, from large machinery to complex equipment. Gear hobbing’s customizability makes it possible to create solutions that are specifically suited to certain industrial requirements.

Marine Applications

Gear hobbing is a crucial process in the marine sector that produces gears for ship propulsion systems. Hobbed gears’ dependability and accuracy guarantee dependable operation in harsh maritime conditions, enhancing the effectiveness and security of marine vehicles.

Renewable Energy

For the production of the gears used in solar power systems and wind turbines, the renewable energy industry depends on gear hobbing. Hobbed gears’ dependability and efficiency enable the sustained production of energy, powering the shift towards cleaner and greener alternatives.

Construction Equipment

Hobbing is a useful process for creating gears for construction equipment, such as excavators and cranes. These gears are strong enough to support large weights and deliver the torque required for a range of construction uses. In construction equipment, gear hobbing guarantees the toughness and longevity of the gears.

Medical Devices

Gear hobbing has uses even in the medical industry. Precision medical equipment frequently uses gears made by hobbing to provide precise and regulated motions. By doing this, the functionality and dependability of vital medical equipment remain guaranteed.

Agricultural Machinery

The manufacturing of gears for tractors combines, and other farming machinery in the agricultural industry depends on gear hobbing. The smooth running of agricultural machinery depends on the dependability and effectiveness of hobbed gears, which affects farm output.

Power Generation

Power plants—renewable or conventional—rely on gears made by hobbing for a variety of uses. Hobbed gears are essential to the stability and effectiveness of power production systems because they transform mechanical energy into electrical power, which powers turbines and generators alike.

Final Words

Gear hobbing is vital in various industries for making gear. It works seamlessly with industrial processes, highlighting its crucial role. As technology improves, gear hobbing evolves, bringing innovation and precision to gear making. This traditional method remains timeless, contributing to machine efficiency and durability. Choosing gear hobbing isn’t just about manufacturing. It’s a strategic decision for top-notch performance and reliability in many industries, guiding progress into the future.