CNC machines are excellent gadgets that turn simple substances into complicated 3D shapes. If you’re wondering how the CNC machining process works and how they make such unique gadgets, you’re in the right place. This article will explain how CNC machines create 3-D shapes, their use, and why they are crucial. Let’s dive in!

What Are CNC Machines?

CNC stands for Computer Numerical Control. These machines are customized with a PC to adjust to rigid commands. The instructions inform the machine how to flow and reduce substances like wood, metal, and plastic. CNC machines use first-rate equipment, including drills, lasers, or routers, to form substances into 3-D paperwork. They can create everything from small mechanical components to large sculptures or furnishings.

How Do CNC Machines Work?

To recognize how CNC machines create 3-D shapes, allow harm down the way into conceivable steps:

Planning the Shape: Initially, a 3D model is created on a PC using a product program like CAD (Computer-Aided Design). The form you want to make in this application is drawn in digital shape. The software program permits the dressmaker to rotate, zoom, and tweak the layout from all angles.

Converting the Design: After the format is complete, the PC converts it into a set number of commands using unique software known as CAM (Computer-Aided Manufacturing). These commands are written in a language known as G-code. G-code tells the CNC system how to waft, where to cut, and how fast to head.

Choosing the Material: The next step is to select the material you need to shape, along with steel, plastic, or timber. The fabric is placed on the CNC gadget’s operating table.

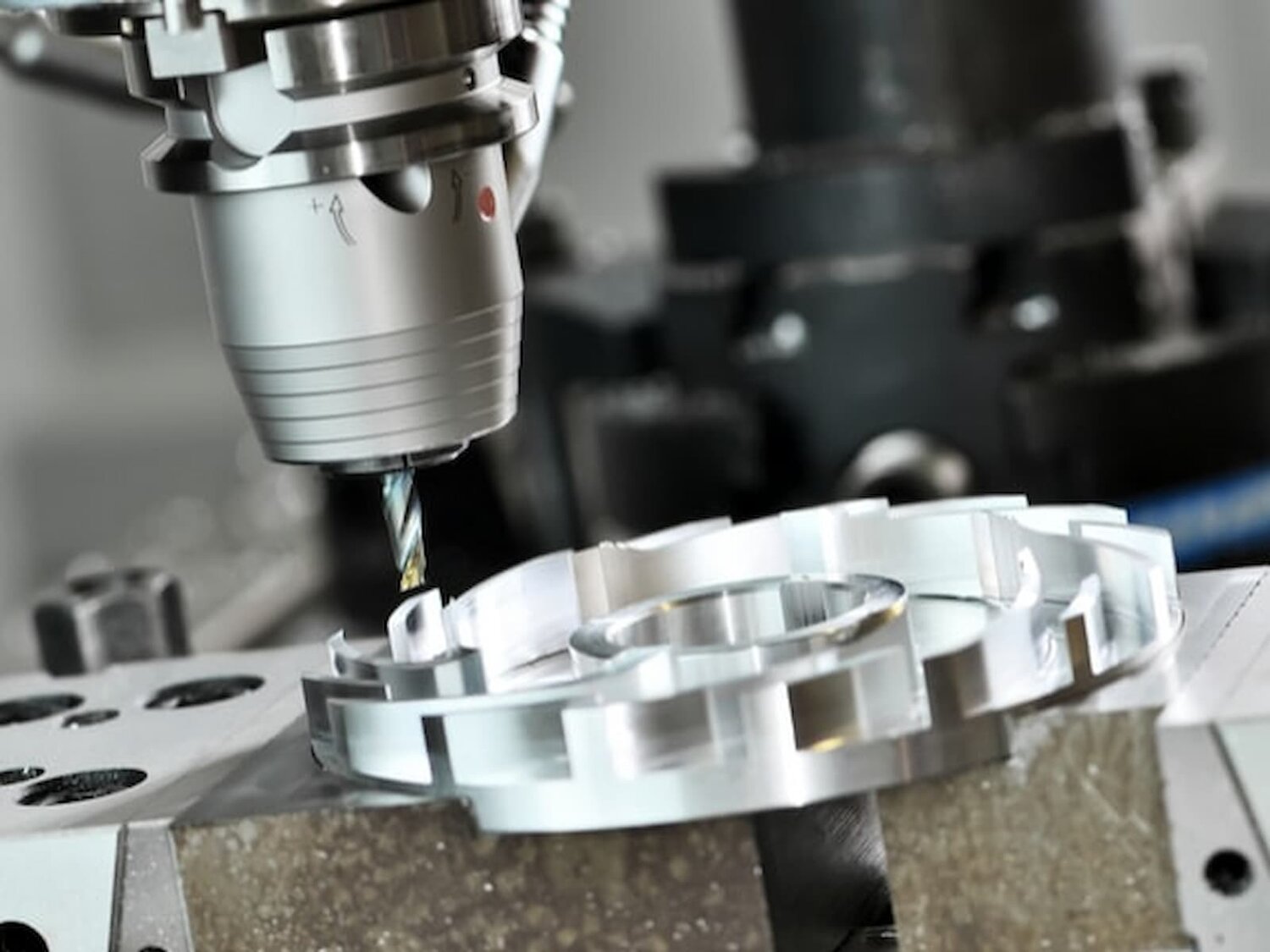

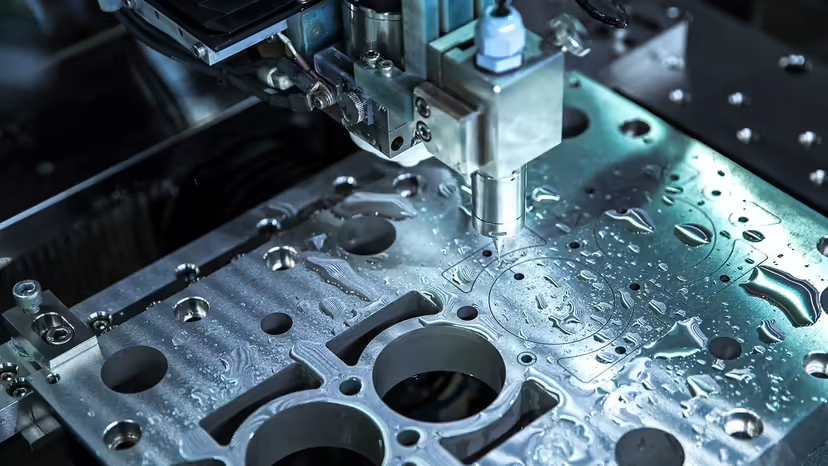

Cutting the Shape: Once the material is prepared, the gadget starts evolving. The gear moves in accordance with the G-code instructions. The machine might use drills, lasers, or blades to reduce and remove components of the cloth. It works layer by layer, step by step, turning a flat piece into a 3-D object.

Finishing Touches: After the cutting, the CNC device may polish or smooth the object. Sometimes, people give the piece a last touch by sanding or painting it.

What Types of 3-D Shapes Can CNC Machines Create?

CNC machines are highly versatile. Here are some sorts of 3-D shapes they can make:

- Mechanical Parts: CNC machines can create gears, engine components, and extraordinary additives used in equipment.

- Custom Sculptures: Artists and designers can use CNC machines to cut particular models from stone or wood.

- Prototypes: Organizations frequently use CNC machines to make model items before they start mass manufacturing.

- Furniture: CNC machines make elegant, custom-designed furniture with elaborate info.

Why Are CNC Machines Important?

Precision manufacturing plays a prominent position in contemporary production. Here’s why:

Precision: CNC machines can create objects with intense accuracy. This approach flawlessly connects the components in shape, which is crucial in aerospace and automobile manufacturing.

Speed: They paint much quicker than humans can. They can shape a chunk of cloth in minutes, but doing it by hand should take hours or days.

Consistency: Once programmed, the CNC milling machine can produce the same object multiple times with no variation. This is right for mass manufacturing, where every piece must be precisely identical.

How Do CNC Machines Create Complex 3-D Shapes?

CNC machines can address complicated designs by moving according to numerous rules. Most CNC lathes have around 3 axes: the X-axes (left and right), Y-axes (front and back), and Z-axes (all over). A few machines have five or extra axes, which permit them to move and pivot according to additional great rules, allowing them to make complex 3D shapes with curves, angles, and deep cuts.

For example, a simple 3-axis CNC gadget can carve out a flat relief sculpture, but a 3-axis machine can carve a complete 3-D determine, including a person’s model. This level of detail and complexity is why automated machining is so broadly utilized in the aerospace, automobile, and art industries.

Last Words

CNC machines are practical tools that can create a wide range of 3-D shapes with precision and speed. From mechanical elements to sculptures and furniture, these machines are remodeling how products are made. With the capacity to handle complicated designs and work with one-of-a-kind substances, CNC programming machines are vital to current manufacturing.

Where can you locate the pleasant CNC machining gadgets?

If you’re seeking out satisfactory CNC machining devices, numerous top websites can help. One of the friendly vendors is Junying CNC Machining Center, which is recognized for its great devices and components. They offer excessive precision production and a broad kind of accurate and reliable CNC machining gear. They also provide distinctive styles of Custom CNC parts. The internet site presents focused product descriptions, reviews, and clean ordering alternatives.

FAQs

Can CNC machines make any 3-D shape?

CNC machines can create almost any 3D shape, depending on the layout and equipment used. They can carve out complicated information and complex shapes with multiple axes.

What substances can CNC machines shape?

CNC machines can work with many substances, such as wood, metal, plastic, and foam. The cloth desired depends on the kind of assignment.

How accurate are CNC machines?

CNC machines are highly correct, frequently within fractions of a millimeter. This makes them best for industries that require unique components, like aerospace and automotive manufacturing.