In CNC machining, surface finishing is a critical step that directly influences the functionality, longevity, and visual appeal of machined parts. Surface finish impacts everything from corrosion resistance to wear performance and is a key consideration in high-precision industries like aerospace, medical, and automotive. As a machining factory, understanding the techniques, applications, and challenges of surface finishing can help you provide a higher level of service and produce parts with enhanced durability and appearance.

Understanding Surface Finishing: Why It Matters

Surface finishing modifies the surface of a machined part to achieve desired characteristics. In high-performance industries, precise surface finishes can improve a part’s performance by reducing friction, increasing resistance to environmental damage, and improving adherence for coatings. It’s also essential for meeting specific aesthetic and cleanliness requirements in consumer-facing and medical applications.

Key reasons to apply surface finishing include:

- Corrosion Resistance: Some materials, like steel, are prone to corrosion. Finishes like anodizing and plating add a protective layer, preventing oxidation and extending part life.

- Improved Wear Resistance: Finishes that harden the surface, such as nitride treatments, help protect against wear in high-friction or high-contact applications.

- Enhanced Appearance: Surface finishes can make parts look cleaner and more polished, improving aesthetic appeal, especially important in visible consumer products.

Common Surface Finishing Techniques in CNC Machining

Various surface finishing techniques are employed depending on the material, application, and desired properties:

Anodizing: Commonly used for aluminum, anodizing creates a durable oxide layer, providing a protective barrier against corrosion. This finish is available in various colors and is widely used in consumer electronics and automotive parts for both durability and aesthetics.

Electroplating: In this process, a metal layer (such as nickel or chrome) is applied to the part using an electric current. Electroplating adds corrosion resistance, increases surface hardness, and offers a shiny, smooth finish, often seen in automotive and industrial components.

Passivation: Primarily used for stainless steel, passivation removes surface contaminants and forms a protective oxide layer to enhance corrosion resistance. This is crucial in industries like aerospace and medical, where parts are exposed to harsh environments.

Bead Blasting: This technique involves blasting the part with glass beads or other abrasive materials to create a matte or textured finish. Bead blasting is often used for aesthetic purposes, providing a clean, uniform appearance.

Polishing: Polishing reduces surface roughness, resulting in a reflective, mirror-like finish. It is often applied to enhance appearance and is also beneficial for components where low friction is required.

Surface Roughness and Measurement

Surface roughness, typically measured in Ra (average roughness), is an essential factor in determining the effectiveness of a surface finish. Different applications require different levels of surface roughness:

High Precision Components: Parts for aerospace or medical applications often need Ra values below 1 μm, as a smoother surface can reduce friction, improve fit, and resist particle adhesion.

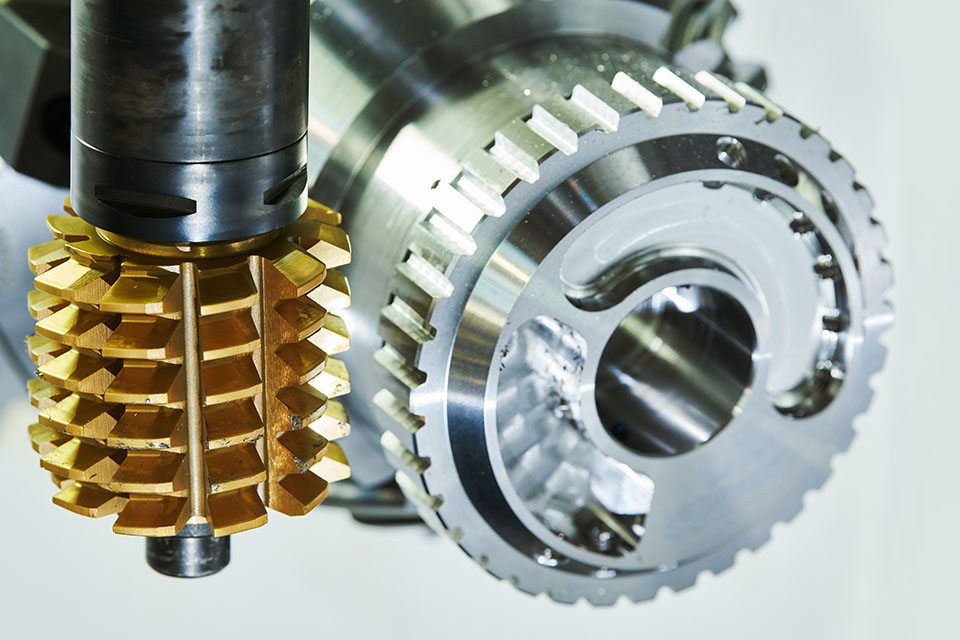

Functional Machined Parts: Industrial parts, such as gears or bearings, generally need Ra values between 1-3 μm to balance smoothness and wear resistance.

To achieve and verify desired surface finishes, many machining shops use contact profilometers or laser-based systems, which measure the Ra value and ensure consistency across parts.

Choosing the Right Surface Finish Based on Application

Selecting the correct surface finish depends on the functional requirements of the part, material properties, and cost constraints:

Aerospace: Parts require lightweight finishes that improve corrosion and wear resistance without adding significant mass. Techniques like anodizing and passivation are common, providing durability and meeting strict weight limitations.

Medical Devices: Surface finishing is critical for sterility and biocompatibility in medical parts. Passivation and polishing are frequently applied to surgical instruments and implants to prevent corrosion and bacterial buildup.

Automotive: Automotive parts face a range of harsh conditions, including high temperatures and moisture. Electroplating and powder coating are popular choices, providing a durable, protective layer that withstands environmental stress.

Challenges in Surface Finishing

Achieving a consistent, high-quality surface finish can be challenging due to factors like material properties, part geometry, and environmental conditions. Common challenges include:

Material Compatibility: Some finishing methods are incompatible with specific materials. For example, anodizing works well on aluminum but not on steel. Understanding material limitations is essential for selecting the appropriate finish.

Complex Geometries: Parts with complex shapes or deep grooves can be difficult to coat or treat evenly. Adjusting application techniques, such as rotating the part during treatment, can help achieve uniform finishes on intricate designs.

Maintaining Dimensional Tolerances: Surface finishes like plating add material, which can affect part dimensions. For parts with tight tolerances, finishes must be carefully applied to avoid impacting functionality.

Environmental Regulations: Many finishing processes, especially those involving chemicals like chrome plating, have environmental implications. Complying with local regulations and implementing eco-friendly finishing options, such as trivalent chromium plating, can help ensure sustainable operations.

Emerging Trends in Surface Finishing for CNC Machining

Technological advancements continue to enhance the field of surface finishing, providing new opportunities for machining shops:

Laser Surface Texturing: Laser texturing creates detailed patterns on the surface, which can improve adhesion, reduce friction, and offer aesthetic appeal. This technique is gaining popularity for high-performance applications, including mold-making and automotive parts.

Nano-Coatings: Nano-coatings provide ultra-thin layers with high hardness, chemical resistance, and anti-reflective properties. Applied through vapor deposition processes, nano-coatings offer advanced protection with minimal impact on part dimensions.

Environmentally Friendly Coatings: New regulations are driving innovation in eco-friendly coatings, such as chromium-free alternatives and water-based solutions. These options offer similar performance to traditional finishes without harmful chemicals.

Conclusion

Surface finishing is a critical aspect of CNC machining, enhancing both functionality and appearance in various parts. By selecting the appropriate finishing techniques, optimizing surface roughness, and staying informed about emerging trends, machining factories can deliver high-quality products that meet demanding industry standards. Mastering surface finishing not only improves part performance but also expands your factory’s service offerings, positioning you as a versatile and quality-driven provider in the competitive machining industry.