Manufacturing industries rely on high-quality parts to ensure smooth production. Defective or misaligned components can lead to costly delays, safety risks, and wasted materials. This is where custom part sorting and inspection services come in. These quality control in manufacturing help businesses maintain strict quality standards by identifying and removing defective parts before they reach customers.

At Junying, we have enjoyed CNC manufacturing services in China for a long time. We provide a one-stop service consisting of CNC machining elements and prototypes. Our procedures are in a cutting-edge facility with superior CNC machining machines, lathes, blasters, and Ultra Sonic washing machines. We even have a group of skilled engineers, operators, and inspectors to bring your designs to life.

What is Part Sorting and Inspection?

Part sorting and inspection are the best manipulation systems used in production. It entails cautiously checking, sorting, and checking out each element earlier than its actions to the subsequent degree. The aim is to encounter defects, inconsistencies, and faults in materials or artistry. This ensures the best terrific elements reach the meeting line or the final customer.

Custom defect detection and removal include visible inspection, dimensional measurements, surface trying out, and valuable checking out. These strategies help producers avoid faulty merchandise, enhance performance, and maintain their market reputation.

The Importance of Part Sorting and Inspection Services

Industrial inspection services play a vital role in the production method. Here’s why these services are critical:

Ensuring Product Quality

Poor exceptional parts can cause device screw-ups, product recalls, and safety troubles. By examining every component, manufacturers can dispose of defects and hold regular options.

Reducing Production Costs

Detecting defects early prevents wasted substances and steeply-priced remodelling. This helps groups store money and increase productivity.

Meeting Industry Standards

Many industries, which include car, aerospace, and clinical device production, require strict, high-quality control. Part inspection ensures compliance with industry guidelines and certifications.

Increasing Customer Satisfaction

Customers expect perfect products. Delivering exceptional elements improves purchaser consideration and brand popularity, central to long-term enterprise growth.

Improving Supply Chain Efficiency

Sorting and examining elements earlier than they attain the subsequent level helps lessen delays, prevent meeting line shutdowns, and improve workflow.

The Process of Our Custom Part Sorting and Inspection Services

At Junying, we comply with an in-depth and systematic technique to ensure pleasant outcomes. Our precision part measurement offerings start with a preliminary assessment.

This first step includes information on the consumer’s needs by inspecting element specs, satisfactory requirements, and practical requirements. After reading those details, we decided on excellent inspection strategies for every challenge.

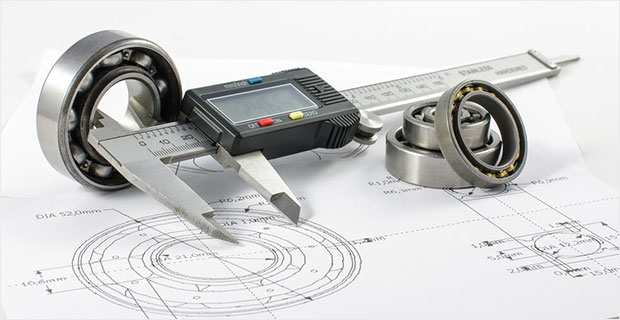

Once the initial assessment is complete, we observe superior inspection methods. Our group uses multiple techniques depending on the material, design, and patron necessities. Visual inspection lets our professionals check for surface defects, shade mismatches, and irregularities. Dimensional inspection involves particular measurements using advanced tools to ensure each component meets specific specifications. Surface testing facilitates awareness of scratches, cracks, or coating issues, ensuring that parts hold their required end and sturdiness. Functional testing evaluates parts in simulated real-world situations to confirm power and performance. Additionally, ultrasonic testing targets inner flaws without damaging the part, ensuring hidden defects no longer compromise the final product’s performance.

After inspection, we flow directly to the sorting technique. We categorise parts based on first-class to ensure the exceptional additives move ahead. Accepted elements meet all outstanding standards and are maintained inside the manufacturing system. Rejected parts no longer meet specifications and are either reworked or discarded. Some parts with minor defects may be repaired or modified to satisfy exceptional standards, falling into the reworkable class. By cautiously sorting and categorising additives, we ensure that the best disease-free elements reach our customers.

Before shipping, we conduct a very last verification. Our specialists double-took at all taken care of elements to ensure they meet the desired requirements. This additional step guarantees that customers acquire the most straightforward, best additives. Once verification is complete, we cautiously per cent the parts to save you damage during transportation. We then ship them according to the consumer’s requirements, ensuring well-timed and steady delivery.

Best Option for Custom Part Sorting and Inspection Services

Choosing the proper automated sorting solutions carrier is crucial for maintaining incredible products. Here’s why Junying is the acceptable option:

- Decades of Experience: We have over 10 years of experience in CNC manufacturing and excellent inspection. Our knowledge permits us to deliver dependable, unique solutions.

- One-Stop Service: We offer CNC parts inspection and prototypes under one roof. Our production and inspection techniques guarantee seamless manufacturing.

- Advanced Equipment: Our facility has many CNC machines, lathes, blasters, ultrasonic washing machines, and superior testing gear, ensuring the best possible results.

- Professional Team: Our group includes exceptionally skilled engineers, operators, and inspectors. They bring technical expertise and attention to each element, ensuring that every part meets strict best requirements.

- Customised Solutions: We tailor our sorting and inspection services to shape every patron’s needs. Whether you want a visual inspection, precision dimension, or practical checking out, we have the correct answer.

- Strict Quality Control: We comply with ISO-licensed satisfactory control procedures. Our inspections help get rid of defects and guarantee constant, first-class parts.

- Fast and Reliable Service: We recognise that point is vital in manufacturing. Our green strategies ensure quick turnaround instances and on-time shipping.

The end of this content

Supply chain quality assurance services are vital for ensuring the highest product quality, decreasing fees, and improving performance. At Junying, we offer top-notch inspection solutions backed by superior devices and a professional crew. With many years of experience in CNC manufacturing, we assist companies in supplying outstanding, disorder-free merchandise to their customers.

If you are looking for a dependent partner in element sorting and inspection, Juning is your first-rate preference. Contact us these days to learn more about our custom solutions!