Modern industries need high-precision machines to create complicated elements. CNC (Computer Numerical Control) machines have converted production by supplying accuracy and velocity. Among them, the 7-axis CNC device stands proud as one of the most advanced. It gives flexibility, efficiency, and precision in machining. But what precisely is a 7-axis CNC machine, and why is it so specific? Let’s learn its operating, kinds, benefits, and applications in detail.

What Is A 7 Axis CNC Machine?

A 7-axis CNC gadget works by shifting in more than one pointer simultaneously. Standard CNC machines typically have 3 or 5 axes. However, an advanced CNC Milling gives even extra flexibility. It can bypass 3 linear axes (X, Y, and Z) while rotating spherical four extra axes (A, B, C, and a secondary rotary axis). This more excellent full-size motion allows for added complicated cuts, decreasing the need for repositioning and guide modifications.

How Does A 7-Axis CNC Machine Work?

Multi-axis CNC Machining works by transferring more than one instruction simultaneously. It has 3 main linear moves along the X, Y, and Z axes. In addition, it rotates around 3 rotational axes (A, B, and C). The 7th axis is often a further rotary movement or tool head adjustment. This allows for complete 360-degree machining without repositioning the workpiece.

The device operates through a pre-programmed computer tool. Engineers create a CAD (Computer-Aided Design) model converted into CNC software. The CNC controller reads this software, directs the device’s vehicles, and drives to move accurately. Since the system can approach the workpiece from a couple of angles, it eliminates the need for guide repositioning. This results in quicker production, higher precision, and less material waste.

Different Types of 7 Axis CNC Machines

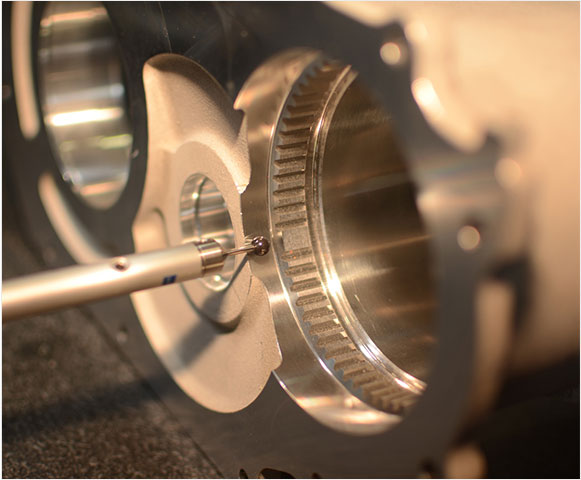

There are numerous types of 7-axis CNC machines designed for particular packages. The 7-axis milling machine is one common type that cuts and shapes steel or other materials. Because they produce substantial parts with clean finishes, these machines are popular in aerospace and automotive manufacturing.

Another type is precision CNC Manufacturing, which focuses on rotational machining. These machines are best for developing cylindrical elements, shafts, and medical implants. The more excellent axes help create complicated shapes without secondary operations.

Some advanced robot hands moreover function as 7-axis CNC machines. These machines are frequently utilized in computerized assembly lines, performing obligations like welding, fabric dealing with, and precision reducing. Their flexibility permits them to conform to extraordinary manufacturing needs without big reprogramming.

Benefits Of Using A 7-Axis CNC Machine

One of the most significant advantages of a 7-axis CNC system is its high precision. These machines can produce specific components with precise tolerances, reducing the risk of making mistakes. Since they might circulate in multiple directions, they eliminate the need for guide repositioning, improving accuracy.

Another key benefit is performance. A CNC Machining Automation can perform numerous obligations in a single setup. This reduces production time and could increase output. Additionally, these machines lower cloth waste, making them fee-powerful.

Flexibility is each machine’s primary advantage. Since they can process the workpiece from various angles, they may create complex geometries that would be impossible with fewer axes. This makes them suitable for industries requiring complicated and outstanding components.

What Industries Use 7-Axis CNC Machines?

Several industries depend on 7-axis CNC machines for their high precision and versatility. One of the most vital clients is the aerospace industry. These machines manufacture aircraft components, including turbine blades, landing systems, and engine components. Their potential to tool complex designs with extraordinary accuracy makes them essential.

The car agency additionally benefits from 7-axis CNC machines. They help create complicated engine components, transmission additives, and custom automobile designs. Since vehicle manufacturing desires precision and efficiency, those machines are a first-rate match.

In the medical business, high-performance CNC Equipment creates surgical contraptions, implants, and prosthetics. Medical devices want to be rather particular, and people machines ensure consistency and reliability in production.

How Does A 7-Axis CNC Machine Compare To A 5-Axis Machine?

A 5-axis CNC machine is already advanced, allowing rotation around additional axes (A and B or A and C) simultaneously with motion along the X, Y, and Z axes. However, a complex CNC machined part takes it a step in addition to every other rotational axis, giving even greater flexibility.

The most significant difference is in complexity and precision. A 7-axis CNC device can manage extra complex designs, decreasing the need for several setups. This makes it pleasant for industries that require surprisingly specific elements. Additionally, a 7-axis device reduces guide intervention, reducing the hazard of human mistakes.

Conversely, a 5-axis CNC gadget is more inexpensive and sufficient for mass packages. A 5-axis tool can be enough for more straightforward production responsibilities. However, a 7-axis CNC system is preferred for high-end manufacturing, where accuracy and performance are essential.

Is A 7-Axis CNC Machine Cost-Effective?

A 7-axis CNC machine is a high-priced funding. The high price comes from its superior era, multiple motion abilities, and complex software program. However, despite the high initial rate, it proves powerful in the long run.

These machines reduce the need for more than one setup and guide repositioning, reducing production time and increasing performance. Since they produce pretty accurate elements, they also reduce material waste, saving charges on raw substances. Additionally, their capability to perform multiple operations in a single setup lowers complex work expenses, as fewer operators are desired.

7 Axis CNC Programming is worth the funding for groups that require high-precision components. It boosts productivity, keeps the best, and guarantees consistency, making it a valuable asset in aggressive industries.

Where can you buy the 7-axis CNC gadget?

While searching for a 7-axis CNC system, I found it is the top choice for Junying CNC Machining Center. Junying offers exquisite 7-axis CNC machines, which may be sincere and beneficial. Their machines are glaringly appropriate for several endeavors, ensuring precise machining. With Junying, you get dumbfounding client assistance and ferocious costs. Whether you need a 7-axis CNC gadget for handling, turning, or entering, Junying offers it. Visit their website to analyze their assurance and locate the correct 7-axis CNC device for your assignments.