Technology has changed the way products are made. One of the most significant innovations in production is 3-D printing. This technique allows people to create objects layer by layer using unique machines. But now, not everyone owns a 3-D printer. This is where 3-D printing offerings are available. These services help individuals and businesses turn digital designs into actual products even without having their printers.

Learn what 3-D printing services are, the materials used, how the way works, and the expenses involved.

What is a 3-D Printing Service?

A 3D printing service is a company that prints objects based on digital 3D models. Additive Manufacturing offerings allow people to create custom factors, prototypes, and particular designs without having their 3D printer. Businesses add their designs, pick materials, and allow professionals to handle printing.

These offerings are applied in many industries, including automobile, healthcare, aerospace, and client products. For example, engineers create prototypes for locating out, and medical examiners use 3-D printing for custom implants. Many organizations use these services to make spare elements and tool briefs.

Instead of investing in expensive materials, agencies can outsource their printing desires to needs. This saves time, reduces fees, and ensures remarkable consequence result serials.

What materials can be used for 3-D printing?

Custom 3D Printing uses quite some materials depending on the desires of the undertaking. Some of the maximum, not unusual ones embody:

Plastics: Plastic is one of the most essential used materials in 3-D printing. PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) are the best alternatives. PLA is eco-friendly and clean to print, while ABS is best.

Resin: Resin-based, total rapid Prototyping produces small elements and smooth surfaces. It is usually used for earrings, dental models, and miniature figures.

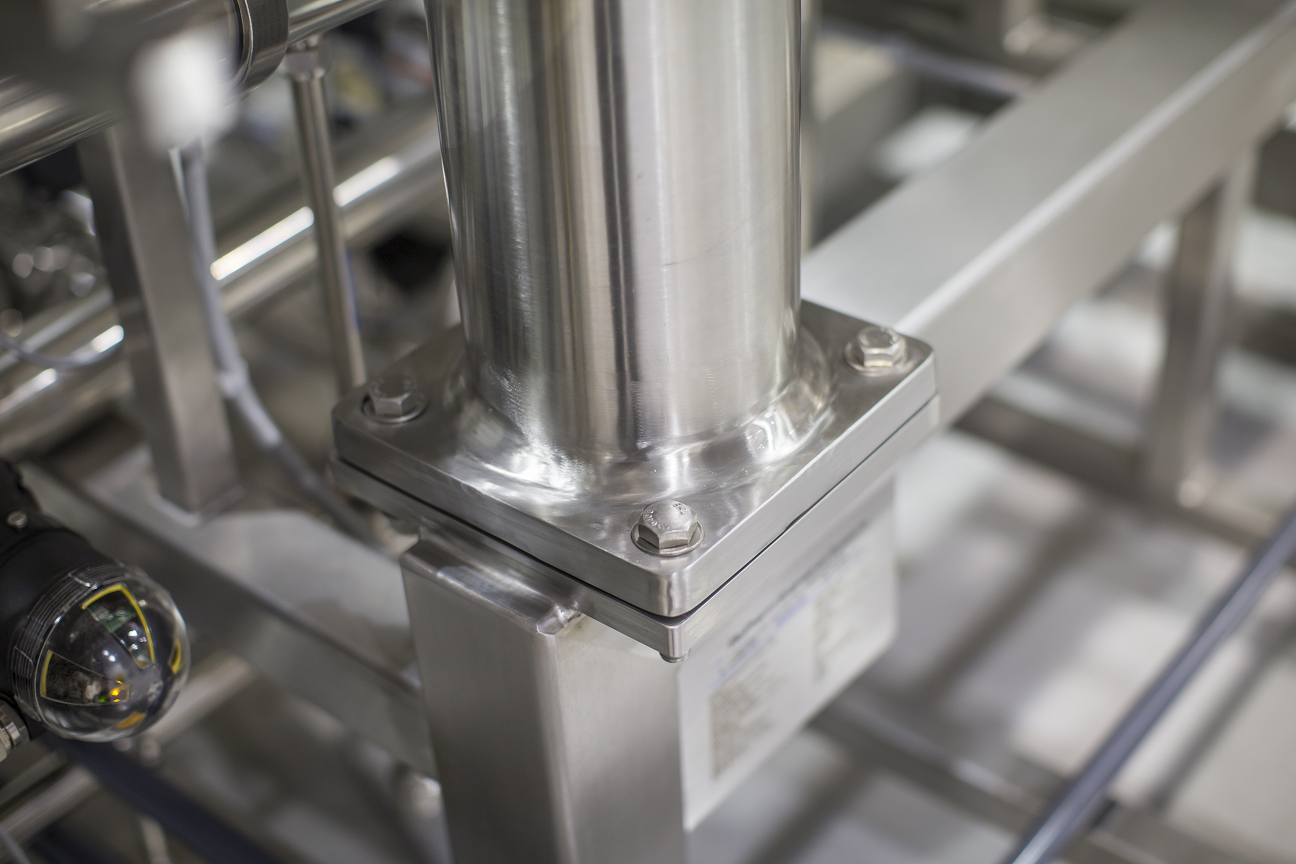

Metals: Metals like stainless steel, aluminum, and titanium are used for outstanding and warm-resistant factors. Industries like aerospace and automobile pick steel 3-D printing for complicated, lightweight designs.

Ceramics: Some agencies print ceramics for work and industrial packages. After printing, those are fired in kilns to harden them.

Composites are materials that blend plastics with carbon fiber, glass, or different reinforcements to create robust, lightweight products.

Each material has its advantages. The exemplary desire is based on the posted object’s purpose, sturdiness, and price.

What are the Processes of 3-D Printing Services?

The 3D Printing Materials include various steps. Each step ensures that the last product meets the layout and incredible requirements.

- Uploading the Design: Customers upload their 3-D version to the issuer company’s platform. The version is typically in STL, OBJ, or excellent 3-D document formats.

- Choosing the Material and Printing Method: The next step is to select a high-quality fabric and printing gadget. Options include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

- Preparing the Model: The company examines the layout for mistakes and adjusts the settings for maximum printing. This step guarantees better print, excessively high quality, and durability.

- Printing the Object: The printer follows the virtual version, growing the object layer via the layer. Depending on the scale and complexity, this technique can take numerous hours or days.

- Post-Processing: Once decided, the item undergoes positioning up-processing. This consists of cleansing, sanding, portraying, and, now and again, warmth treatments to enhance sturdiness and appearance.

- Quality Check and Shipping: The closing product is inspected for defects before being shipped to the customer.

How Much Does 3-D Printing Cost?

The cost of 3D Printed Parts is predicated upon numerous factors:

Material: Plastic is less expensive than steel or resin.

Size and Complexity: Larger and more precise prints charge extra.

Printing Method: Some strategies, like SLA and SLS, are more highly priced than number one FDM printing.

Quantity: Bulk orders may lower the price according to the unit.

Post-Processing: Additional completing, like sanding or painting, increases the fee.

On average, a small plastic print may cost around $10–$50, while more significant or high-detail metal parts can range from $100 to several thousand dollars. Getting quotes from more than one provider allows for finding a high cost.

Consider When Choosing a Trusted 3-D Printing Service Provider.

Finding a dependable Industrial 3D Printing provider is vital for splendid outcomes. Here are key elements to consider:

- Experience and Reputation: Look for companies with an examined song report. Companies like Junying, with a few years of experience, provide reliability and information.

- Material and Technology Options: A proper agency must offer diverse materials and printing techniques to fit your wishes.

- Quality Control: Ensure they’ve got a nice checking method to avoid errors and defects.

- Cost and Turnaround Time: Compare expenses and shipping times to discover stability between price and pace.

- Customer Support: A good provider organization must provide responsive help, reply to questions, and resolve problems quickly.

Where Can I Find a Reliable Online 3-D Printing Service?

Many online systems provide 3-D printing. Junying CNC Machining Center is a trusted name for businesses that want excellent custom production. With many years of experience in CNC machining offerings in China, Junying affords one-prevent solutions for OEM clients. Their services include CNC machining additives and prototypes, ensuring precision and sturdiness.

Junying operates with 100% secure CNC machines, lathes, blasters, and ultrasonic washing machines. The industry has as a substitute a professional company of engineers, operators, and inspectors who make consumer designs a reality. Their commitment to top performance and consumer pleasure makes them an excellent preference for online 3D Printing and CNC machining wishes.