Sheet metal fabrication is a critical part of production. It helps create durable and specific metal components for unique industries. This method is essential in producing splendid products, from vehicles to aerospace. Many organizations choose sheet metal fabrication for its flexibility, energy, and cost-effectiveness.

We discuss what is sheet metal fabrication, how it works, its key advantages, and its applications.

What is Sheet Metal Fabrication?

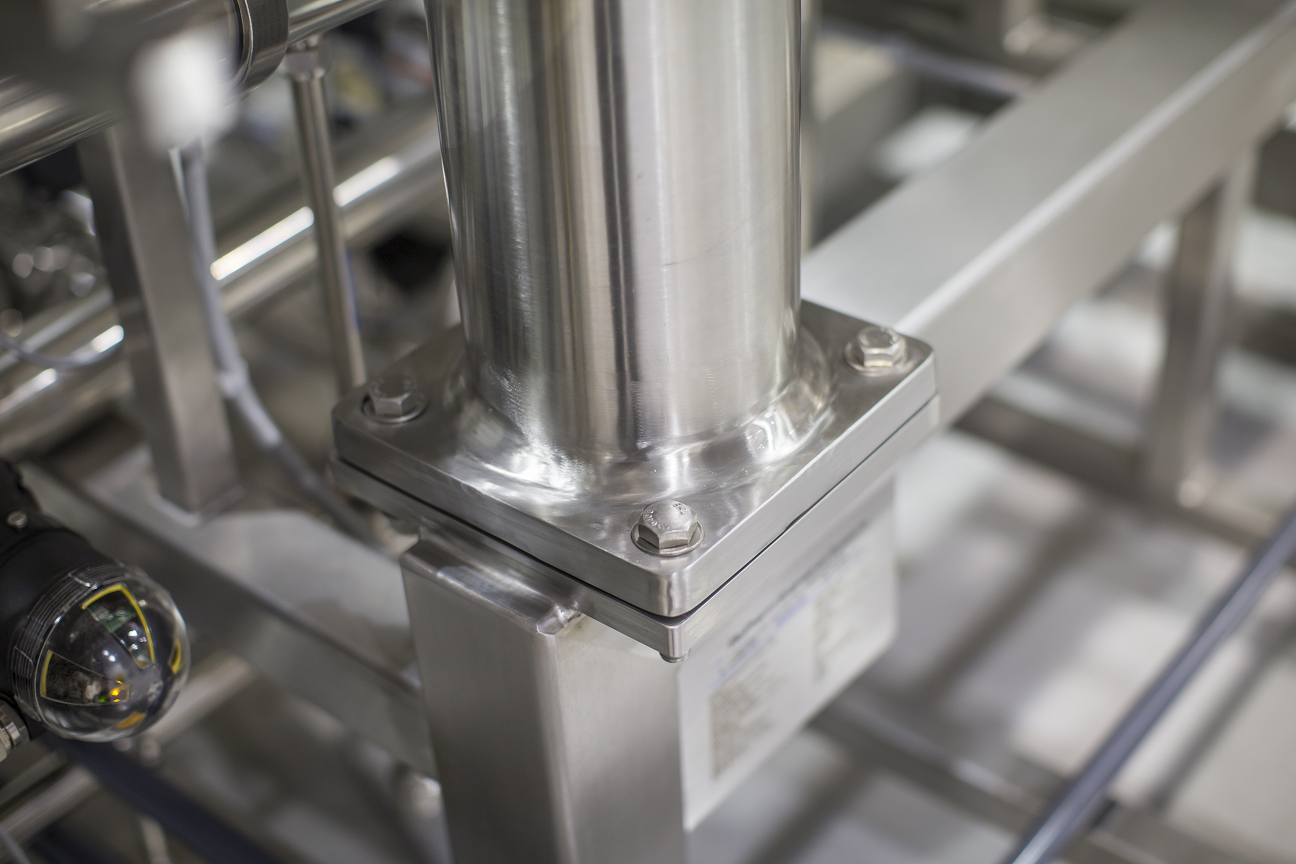

Sheet metal fabrication involves shaping, cutting, and assembling metal sheets to create different products. It involves various techniques, such as bending, welding, and stamping. Manufacturers fabricate parts using other metals, such as aluminum, steel, brass, and copper.

How Does Sheet Metal Fabrication Work?

Sheet metal fabrication follows a series of steps to transform raw metal sheets into finished products. The gadget begins designing the product using a computer-aided design (CAD) program. After finalizing the format, the metal sheet is reduced into the preferred form using lasers, plasma, or water jet-reducing machines.

Once the cut price is complete, the next step is bending and forming. Machines like press brakes form the steel into the desired shape. If desired, welding and assembling techniques are part of the outstanding metal quantities.

11 Top Benefits of Sheet Metal Fabrication

High Durability

Sheet metal is strong and resistant to wear and tear. It can face high temperatures, corrosion, and exceptional results, making it appropriate for extended use in harsh environments.

Lightweight Yet Strong

Despite its energy, sheet metal is notably lightweight, making transportation and setting up a good buy less complicated—industries like vehicle and aerospace benefit from its high electricity-to-weight ratio.

Cost-Effective

Sheet metal welding techniques reduce material waste and manufacturing fees. Advanced CNC machines perform particular reductions, minimizing errors. This technique is suitable for both small—and large-scale production.

Customization Flexibility

Manufacturers can create custom designs based totally on specific requirements. CAD software program software utility allows businesses to adjust shapes, sizes, and patterns to meet incredible goals, permitting more modern product designs.

Scalability for Mass Production

Sheet metal fabrication facilitates small and big production volumes. Corporations can continuously and successfully manufacture large quantities as soon as possible because the preliminary layout and setup are entire.

Faster Production Time

Modern fabrication strategies, including laser discount and CNC machining, accelerate manufacturing. This results in faster turnaround times, permitting companies to meet tight remaining dates.

Environmentally Friendly

Many sheet metal materials are recyclable, lowering waste and promoting sustainable production practices. Companies that use sheet metal fabrication contribute to greener surroundings.

High Precision and Accuracy

CNC machines ensure that each element meets the correct measurements. This degree of precision reduces errors and improves the best of the very last product; this is vital in industries like electronics and scientific systems.

Strong Resistance to Corrosion

Metal sheets may be lined with protective layers to withstand rust and corrosion. This makes Industrial metal cutting suitable for outdoor structures and marine packages.

Easy Maintenance

Sheet metal products require minimum maintenance. They can no longer be left without trouble, damage, cracking, or deformation. This reduces healing costs and guarantees long-lasting performance.

Versatile Applications

Precision metal fabrication is used in numerous industries, including manufacturing, motors, aerospace, and consumer gadgets. It permits businesses to create innumerable products to meet specific market needs.

Applications of Sheet Metal Fabrication

Sheet metal fabrication is appreciably used in precise industries. In the car industry, it’s used to make cars, our bodies, frames, and engine additives. Steel metals are used for roofing, HVAC ducts, and constructing structures in creation.

The aerospace industry fabricates sheet metal for plane panels, engine components, and beneficial aid systems. In electronics, metal sheets create enclosures, brackets, and heat sinks. Even the clinical organization benefits from fabricated steel additives for surgical and hospital devices.

Top CNC Manufacturing Services Provider in China

Regarding CNC machining services in China, Junying is a leading corporation. With extensive experience, Junying provides splendid CNC machining elements and prototypes. The employer specializes in the best solutions, coping with all strategies from the format to the last production.

Junying operates with top CNC machines, lathes, and every other ultra-modern system. They use ultrasonic washing machines and precision blasters to ensure top-quality finishing. Their professional crew of engineers, operators, and inspectors guarantees that each consumer’s format is modified into truth with accuracy and overall performance.

Key Takeaways

The metal forming process is crucial and offers durability, flexibility, and price effectiveness. Its excessive precision, fast manufacturing, and massive applications make it desired by hundreds of industries. Steel and aluminum fabrication generate outstanding vehicles, manufacturing, aerospace, and electronics products.

Junying gives the best answers in China for organizations attempting to find reliable CNC production offerings. Their advanced technology and professional group make them dependent on accomplices in the employer. Investing in custom sheet metal manufacturing ensures a considerable, long-lasting, customizable product that meets various industry needs.