CNC milling is a standard manufacturing process used in many industries. It plays a big role in creating precise and complex parts. But what is CNC milling? How does it work? And which industries rely upon it? We can find out the entirety you need to realize about CNC machining, from its operating method to the materials used and the benefits it gives. You may learn how to pick out the proper CNC milling provider.

What is CNC Milling?

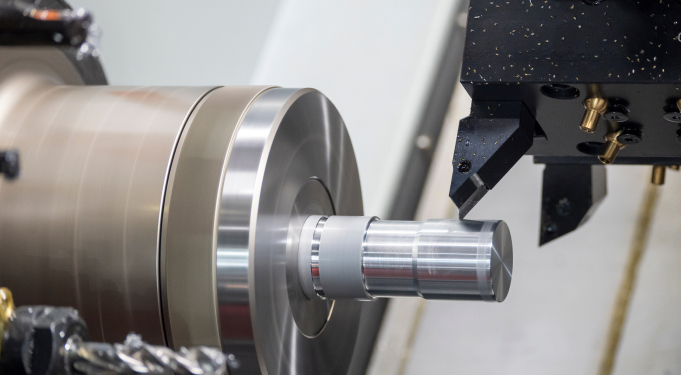

CNC milling is a machining tool that uses automatic controls to remove clothes from a workpiece. The term “CNC” stands for Computer Numerical Control. This way, a computer software program directs the milling system to lessen, shape, and drill materials into particular work. Unlike guide milling, the Milling machine guarantees accuracy, pace, and repeatability.

How Does CNC Milling Work?

The CNC milling technique starts with a design. Engineers create a 3D version using CAD (Computer-Aided Design) software. This format is transformed into system code, which tells the milling machine what to do.

The device has a rotating reducing device that removes fabric from the workpiece. The workpiece is secured on a table that moves in remarkable instructions. The reducing tool moves alongside multiple axes to shape the fabric precisely. Modern precision manufacturing should have as many as five axes, permitting them to create highly accurate complex components.

What Industries Use CNC Milling?

Aerospace Industry

The aerospace industry requires very unique and massive additives. CNC milling creates plane additives like turbine blades, engine components, and structural frames. Its functionality in artwork with moderate metals, including aluminum and titanium, makes CNC milling exquisite for aerospace programs.

Automotive Industry

CNC milling is appreciably used in the automobile region to fabricate engine elements, transmission additives, and custom vehicle accessories. It allows the production of complicated shapes that might be difficult to create using traditional techniques. The automobile industry benefits from CNC milling’s speed and accuracy, which help decorate vehicles’ daily performance.

Medical Industry

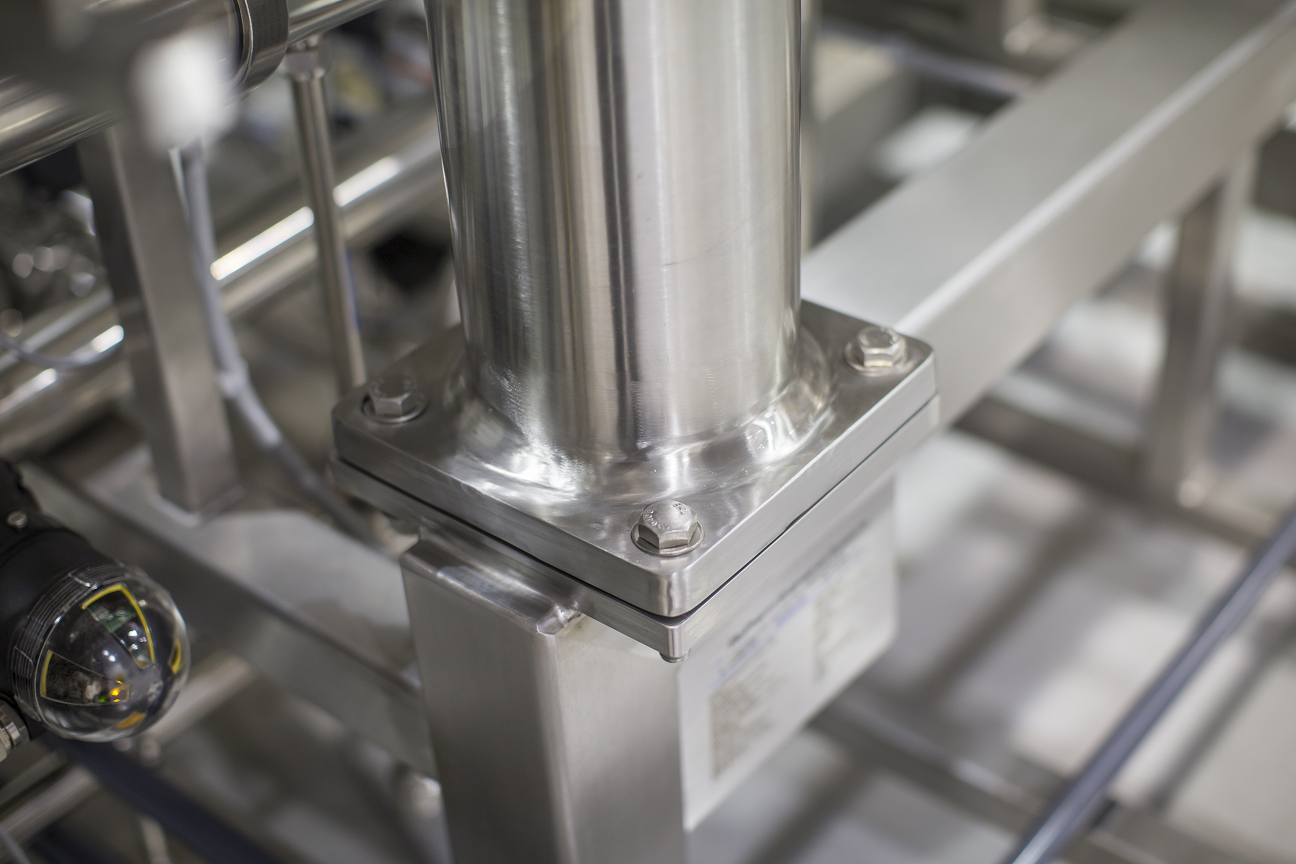

The scientific situation is based on CNC milling to create surgical gadgets, prosthetic limbs, and scientific implants. Since precision is critical in this industry, Computer Numerical Control milling ensures that every element meets strict top necessities. Materials at the side of stainless steel and titanium are typically utilized in clinical applications.

Electronics Industry

CNC milling is used within the electronics corporation to fabricate circuit boards, warm-temperature sinks, and casings for digital gadgets. Its capability to create small and complex components makes Metal fabrication a super preference for this industry.

Defense and Military

The protection organizations require surprisingly durable and unique weapons, motors, and shielding equipment additives. CNC milling is used to manufacture firearm additives, communication devices, and military vehicle components. Its ability to work with numerous metals and plastics makes it a precious tool for protection production.

Construction and Architecture

CNC milling is likewise applied in production and structure to create custom-designed metal and timber structures. From ornamental panels to metal fittings, CNC milling permits progressive designs to be delivered to life.

What are the CNC Milling Materials?

CNC milling can work with many materials, making it a bendy machining procedure. Some of the most unusual substances consist of:

Metals

- Aluminum: Lightweight, sturdy, and corrosion-resistant, carried out in aerospace and automobile elements.

- Steel: Durable and robust, utilized in company devices and medical devices.

- Titanium: Lightweight and pretty evidence in competition to corrosion, finished in aerospace and clinical implants.

- Brass: Brass is utilized in electronics and ornamental components due to its machinability.

Plastics

- ABS: ABS is carried out in car and client merchandise because of its durability and impact resistance.

- Nylon: Durable and flexible, carried out in mechanical and commercial additives.

- Acrylic: Transparent and lightweight, utilized in symptoms and shows.

Wood

- Hardwood: Used in fixtures and decorative applications.

- Plywood: Used for construction and layout initiatives.

What are the Advantages of CNC Milling?

CNC milling offers many advantages over conventional production strategies. Here are some key benefits:

- High Precision: CNC milling produces distinctly correct elements with minimum errors. Laptop control guarantees consistency in every product.

- Efficiency and Speed: Since CNC machines perform mechanically, they can produce parts masses faster than guide techniques. This hastens manufacturing and reduces expenses.

- Complex Designs: With multi-axis milling, CNC machines can create complicated shapes that are probably not feasible with manual milling.

- Reduced Waste: Since CNC milling follows precise commands, it reduces cloth waste. This helps save costs and makes the device more environmentally friendly.

- Scalability: CNC milling is ideal for both small and big production runs. It allows corporations to scale their manufacturing as needed.

How Do I Choose the Right CNC Milling Service Provider?

Choosing the proper CNC machining services company is vital to ensure extraordinary performance. Here are some key factors to endure in thoughts:

Experience and Expertise

Look for a service provider with years of experience in CNC milling. An expert group guarantees precision and brilliant results.

Equipment and Technology

Check if the issuer makes use of modern CNC milling machines. Advanced era guarantees better accuracy and performance.

Material Capabilities

Make sure the issuer can work with the substances you want. Whether it’s metal, plastic, or wood, they should be able to handle top-quality materials.

Quality Control

A correct CNC milling company has to have strict, excellent control techniques. Ask about their inspection methods and certifications to ensure high necessities are met.

Customization and Flexibility

If you want custom elements, choose an employer that offers customization offerings. They should be flexible enough to meet your design necessities.

Cost and Lead Time

Compare pricing and lead instances among splendid companies. Choose one that offers excellent stability between rate and transport time without compromising on quality.

CNC Milling with ‘Junying CNC Machining Center’

Junying CNC Machining Center is a trusted name for top-quality custom milling parts offerings. With years of experience, Junying focuses on high-precision CNC machining for several industries. They offer one-stop solutions that encompass precise manufacturing and prototyping.

Junying’s centers have many superior multi-axis milling methods and specific devices. Their team of professional engineers and operators ensures that each element meets the very best requirements. Whether you need a single prototype or mass production, Junying can deliver it.

The industry’s determination to be green and the patron’s pride set them apart. The artists work carefully with clients to tailor their designs to their lives. If you’re seeking dependable CNC machining offerings, Junying is a pleasant desire.