Making high-quality products is very important, especially in manufacturing. One small mistake can lead to big problems. This is why many companies use a service called First Article Inspection, or FAI for short. FAI helps make sure the very first product made is just right. It checks if everything matches the design before making more. This service saves time, money, and avoids problems later.

We’ll explain what First Article Inspection is, its advantages, and even some negative aspects.

What is First Article Inspection?

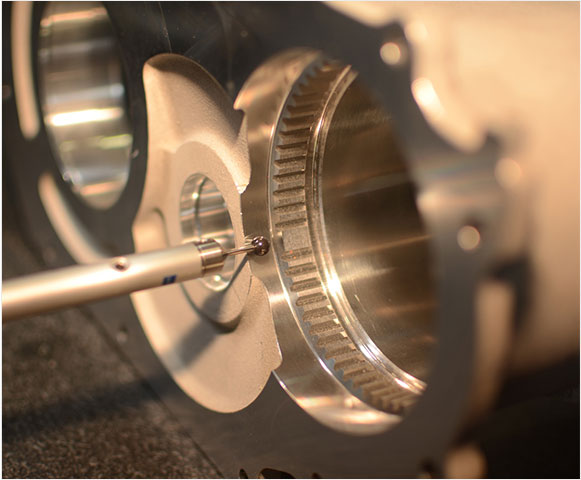

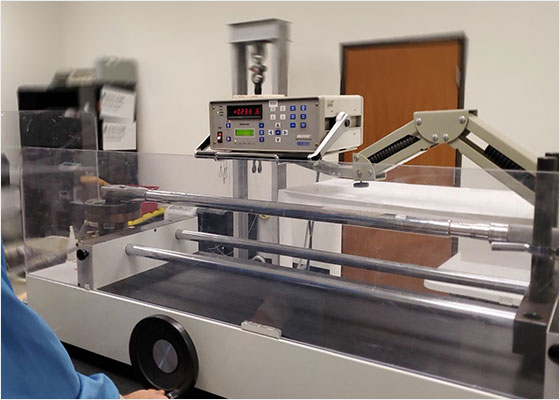

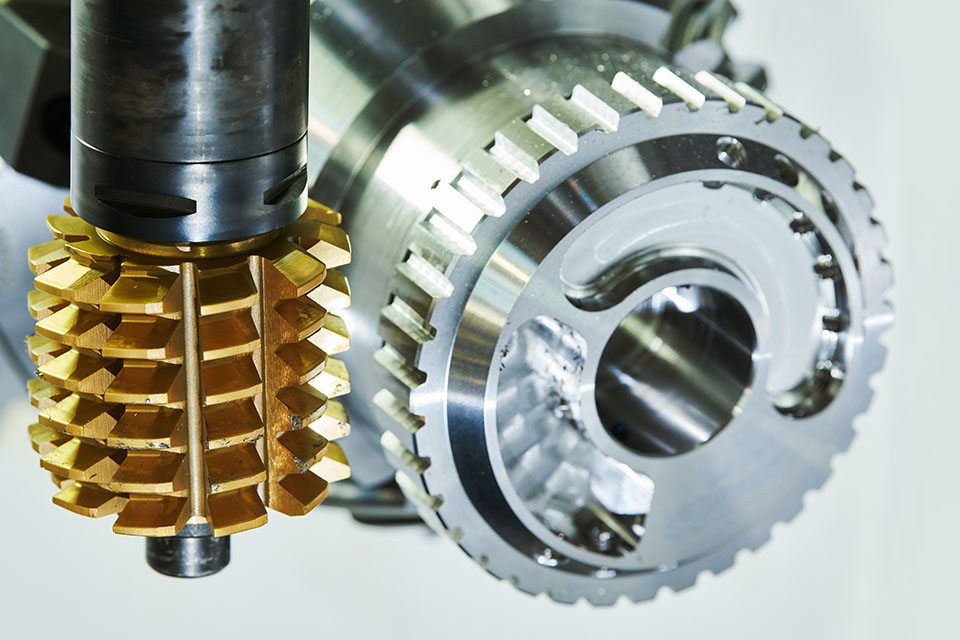

First Article Inspection, also known as FAI, is a detailed check of the first product made in a brand-new batch. It is regularly used in CNC machining and other production procedures. The aim is to ensure the primary component suits the design and drawings precisely.

Imagine you’re making a steel element for a gadget. You need to make certain the first piece is ideal. The FAI process crew will check all sizes, shapes, and substances. They will evaluate the completed element against the blueprint. If something is wrong, modifications may be made earlier than adding extra elements.

You don’t waste time or money. You avoid sending bad elements to your customer. FAI offers peace of mind that production is starting properly.

7 Advantages of Using First Article Inspection Service

Helps Find Problems Early

The first-class time to find a mistake is at the beginning. The initial part inspection tests the first item made. If something isn’t always proper, it is simple to fix earlier than making extra. This saves time and substances. Finding and solving issues early way fewer delays and much less waste.

Saves Time and Money

Without FAI, you can produce many parts earlier than finding a mistake. That can feel plenty. You may need to begin over or repair the whole lot. Quality control in manufacturing enables avoid this. It finds errors early, so you’d best make components that meet the layout. In this manner, you use fewer substances and avoid high-priced do-overs.

Increases Product Quality

FAI looks closely at size, form, and materials. It checks if the product meets the precise design. When the whole lot is checked at the start, you may make sure the rest is right too. This continues to make your product pleasant and your customers glad.

Builds Trust with Customers

When your purchaser knows you use FAI, they experience more security. They know you check the product cautiously. This builds trust. Customers want to paintings with folks who care about doing things right. CNC part inspection indicates that you are approximately pleasant.

Good for Complex Designs

Some components are simple. Others are very complex, with many steps. Complex parts are more likely to have errors. FAI could be very useful here. It cautiously tests each part of the design. This makes sure the product is accurate, although the job is difficult.

Supports OEM and Custom Projects

Many businesses make custom products for OEM (Original Equipment Manufacturer) clients. Each patron has special wishes. A dimensional inspection report ensures certain the primary product meets those desires. This may be very beneficial for different tasks or special orders. It indicates you may follow unique requests exactly.

Improves the Production Process

FAI can factor out where the procedure needs to be exchanged. Maybe a device isn’t reducing efficiently. Or maybe the raw fabric isn’t strong enough. When prototype verification reveals the hassle, the team can restore it. This makes the entire system better. It ends in quicker and smoother production.

Disadvantages of Using First Article Inspection

It Takes Extra Time at the Start

FAI adds a step before complete production. This process is to wait a little longer before making a complete batch. For some initiatives, this postponement can be a problem, especially if you’re in a hurry. But this short wait frequently saves more time later.

It May Cost More Upfront

FAI offerings are not free. You have to pay for the time, gear, and business to do the exams. For small projects, this cost might seem high. But in most cases, the cash you keep using to avoid mistakes is tons greater than the cost of a manufacturing compliance check.

Find the Best First Article Inspection Service Company in China

Finding an amazing FAI service in China is not hard in case you recognize what to look for. You need an employer that has revel in, the right equipment, and a strong business. One of the best alternatives is Junying.

Why Junying Stands Out

Junying is popular in China for its great FAI offerings. They were in CNC production for decades. Their crew is familiar with the way to degree each component with tremendous care. They use advanced machines to ensure everything is perfect.

Junying’s centers are complete with present equipment like CNC machines, lathes, blasters, and ultrasonic washers. These machines assist them in making very accurate parts. They have educated engineers and inspectors who test each component closely. They intend to deliver top-quality service each time.

One-Stop CNC Services

Junying doesn’t simply offer inspection. They also make CNC additives and prototypes. With this process, you could agree with them from the beginning of your layout to the completed component. Their full-service technique makes the process easy and fast.

Work Closely with Clients

Junying listens carefully to what each consumer wishes. If you are an OEM or need custom work, they may comply with your designs precisely. They care about doing things right the first time. Their team works with you from design to transport.

Trusted with the aid of Many Companies

Junying’s dedication to quality and customer support has made them the best choice in China. Many companies believe in them for FAI and different CNC services. When you pick Junying, you get more than a provider—you get a companion who cares approximately your achievement.