In manufacturing, making sure that every part works properly is very important. If a part is broken or not made right, it can cause big problems later. That’s where Part Sorting & Inspection Service comes in. This automated quality control service helps check each part to make sure it meets the right standards before it’s used in production. We’ll explain what Part Sorting & Inspection is, why it’s important, what types of parts are inspected, and how to find these services for your business.

What is Part Sorting & Inspection Service?

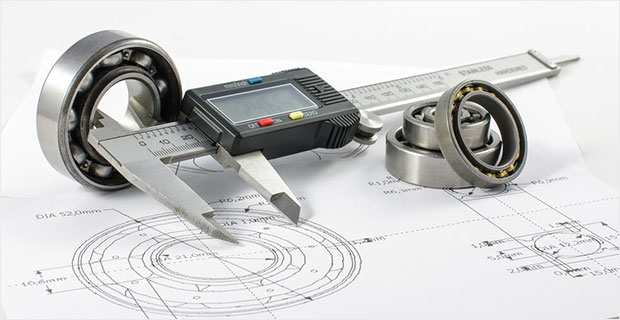

Part Sorting and Inspection is a process where parts are cautiously checked for any defects earlier than they’re used in production. The purpose is to locate and separate the bad components from the best ones. For instance, if a company makes vehicle engines, each component, like bolts or pistons, ought to be checked for exquisite. If any element is damaged or has a small flaw, it’s eliminated to avoid issues within the very last product.

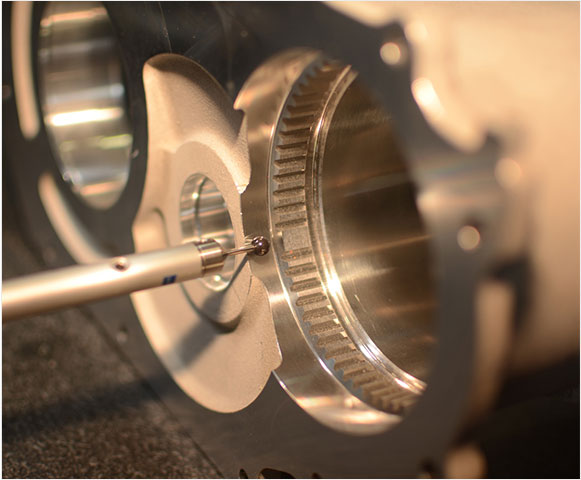

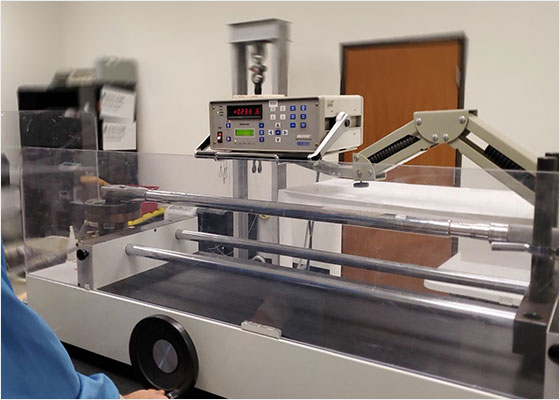

This process may be completed by hand or the use of machines that robotically take a look at the components. In each case, the intention is the same: to ensure handiest remarkable elements are applied in production.

Why is Part Sorting and Inspection Important?

Part Sorting and Inspection might be very essential for some reasons. First, Industrial parts inspection helps avoid away from problems with the final product. If terrible elements are used, the very last product may not work properly, or worse, it can able to broken.

Second, sorting and analyzing components early can save money and time. If awful parts are determined later in production, it can result in delays and additional fees to recover from the hassle. By catching those problems early, agencies can avoid these additional expenses.

Finally, inspecting elements permits observing business rules and requirements. Many industries, like healthcare or the car industry, have strict rules to make sure the goods are secure. By using assembly line inspection, organizations can make sure they meet those essential necessities.

How Can I Get Part Sorting and Inspection Services for My Business?

Here are some things to consider while choosing a business:

Experience: Look for a business that specialises in your industry. If they understand the perfect additives you use, they’ll be better at reading them.

Technology: Some agencies use superior machines to investigate components. These machines can be quicker and greater accurate than guided inspections. Depending on your desires, you may want an industry that makes use of those machines.

Turnaround time: Make positive the enterprise can check out your components in a well timed manner. You don’t need delays for your production line, so it’s critical to find out a enterprise which can meet your time limits.

Custom offerings: Some organizations offer custom services, in which the sorting and inspection are tailor-made to the specific needs of your components. This may be mainly beneficial if you have complex additives or precise necessities.

It’s important to perform a little research and select a reliable carrier provider that could meet your business needs.

Reliable Place for Custom Part Sorting & Inspection Service

When searching for a reliable company to assist with Part Sorting and Inspection, Junying is an excellent alternative. They have over a decade of enjoy in CNC (Computer Numerical Control) production services in China. They appear to supply exceptional CNC machining services and CNC machining prototypes. If you need defect detection systems for your company, Junying will let you get exactly what you want.

Junying is also awesome for custom-made order sorting and inspection services. In this manner, they could tailor their inspection process to suit your precise wishes. Whether you’re manufacturing metal elements, plastic additives, or electronics, Junying’s crew can kind and look at each element with care. They use superior generation to ensure that each component is as much as the best requirements earlier than it’s utilized in production.

Another benefit of working with Junying is their one-stop service. You can get CNC machining and inspection services from the same organization. This saves you time and cash, as you don’t need to address multiple provider carriers.

With Junying’s decades of revel in, they recognize the importance of pleasant manipulate. They make sure that each part is inspected thoroughly before it’s used, so you can be confident that your final product might be safe and outstanding.

Final Words for Part Sorting & Inspection

Part Sorting and Inspection is a crucial part of the production technique. Machine vision inspection helps make certain that the simplest incredible components are used, which results in higher products and fewer problems later on. Whether you’re within the automotive, electronics, or production organisation, this provider is critical for preserving nice and meeting safety standards.

If you want precision part sorting offerings for your commercial enterprise, search for a reliable provider like Junying. With their experience and custom offerings, they will let you get the fantastic additives for your production line. Working with a dependable associate ensures that your factors meet the very fine necessities, saving you money and time in the long run.

By the use of non-destructive testing services, you could enhance your manufacturing method, keep away from errors, and create higher-quality products for your clients.