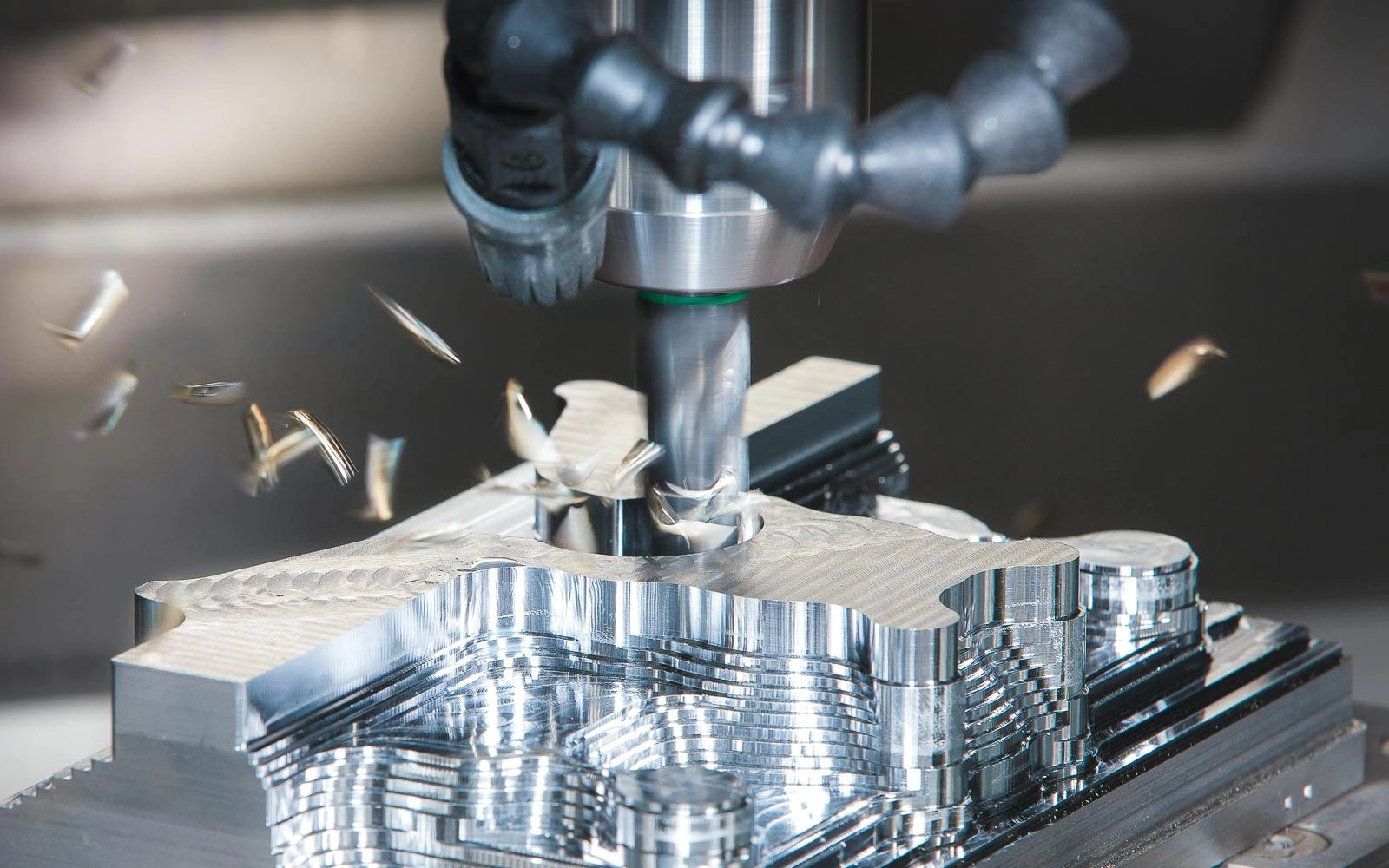

CNC (Computer Numerical Control) machines are famous in manufacturing. They allow for precise cuts and complicated shapes in diverse materials. Many users want to know if they can upload a 4th axis to their CNC milling. Adding a 4th axis can boost the machine’s skills, permit extra complex designs, and step forward performance. Let’s explore if that is possible and what it involves.

What is a 4th Axis?

Before diving into the data, we should figure out a 4 th axis. In CNC machining, the initial 3 axes are X, Y, and Z. The X-axis runs left to right, and the Y-axis pushes ahead and reverses. The Z-axis moves up and down. The 4th axis, called the A-axis, usually rotates across the X-axis. This rotation allows the machine to work on distinctive sides of a workpiece without changing its position.

Can I Add a 4th Axis to Any CNC Machine?

The short answer is that it depends on your CNC router. Not all CNC machines can accommodate a 4th axis. However, many may be upgraded if certain conditions are met. Here are a few elements to remember when considering including a 4th axis.

Compatibility with Existing Hardware

First, check if your CNC gadget helps a 4th axis. Some machines are designed to add extra axes effortlessly, while others might require giant adjustments. Look at the producer’s specs or manual. You may also seek advice directly from the manufacturer. They can offer steerage on whether your version can assist a 4th axis.

Control Software

CNC machines rely on control software programs to operate. Adding a 4th axis can also require updates to this software program. Some software programs can manage multiple axes simultaneously, as others can’t. If your current software program no longer assists a 4th axis, you may want to upgrade to an extra superior machine. Pick a software program compatible with your CNC machining and has the necessary capabilities.

Mechanical Modifications

Adding a 4th axis might require mechanical changes for your system. This should involve adding new additives like a rotary table or a spindle. Depending on your system’s layout, you could also want to alter the body or wiring. These changes can be complex and require expert assistance.

Cost Considerations

Before adding a 4th axis, remember the prices involved. Upgrading your system can be costly. Costs may include buying new hardware, software program enhancements, and ability installation charges. You must weigh these costs against the advantages you expect from the delivered abilities.

Skill Level

Adding a 4th axis may be a technical system. You may want assistance if you need to become more familiar with equipment or electronics. It’s critical to have a person informed to assist with the installation. This ensures that the entire project is achieved effectively and safely.

Benefits of Adding a 4th Axis

Now that we’ve discussed the feasibility, permit’s study the blessings of adding a 4th axis. Here are some advantages you could gain:

- Increased Precision: A 4th axis allows for extra particular cuts and angles. You can create complex shapes that could be difficult with only 3 axes.

- Reduced Setup Time: A 4th axis allows you to paint on multiple facets of a workpiece without repositioning it, reducing setup time and increasing efficiency.

- Enhanced Creativity: A 4th axis opens up new possibilities for design. You can create more elaborate and designated portions that were previously unfeasible.

Where Do I Find Cnc Machine Parts?

Finding a reliable issuer that offers excellent CNC software parts is essential if you’re seeking CNC machine components. While several resources online provide a wide variety of CNC machine factors, the best place to get them is the Junying CNC Machining Center. They are known for supplying precision CNC tools that meet enterprise requirements.

The supplier of CNC spare components is Junying CNC Machining Center. You’ll find everything from frames and slicing systems to spindles and controllers. They offer long-lasting and unique factors for all sorts of CNC programming. Whether you need custom CNC parts for a repair or an upgrade, Junying has you covered. Their merchandise is designed to enhance performance and increase the life of your device.

Frequently Asked Questions (FAQs)

Can I add a 4th axis to a hobby CNC device?

Many interesting CNC machines may be upgraded to include a 4th axis. However, test compatibility and remember mechanical modifications.

What varieties of 4th axis options are to be had?

Standard options include rotary tables and listed heads. These gadgets allow for unique rotation and may be brought to most CNC machines.

Will I need a new software program for my CNC device?

It depends on your cutting-edge software. Some CNC control software can handle a 4th axis, while others may require an upgrade to work efficiently.

Final Thoughts

Adding a 4th axis in a CNC system is feasible but requires careful consideration. You should test compatibility, manipulate software programs, and make mechanical changes. Additionally, take into account the fees and your ability degree. The benefits of extended precision and reduced setup time can be significant. If carried out effectively, including a 4th axis can enhance your CNC machine’s capabilities, allowing you to create extra complex and unique designs. Always consult professionals or skilled customers if you need more clarification. You can efficiently improve your CNC fabrication and properly amplify your innovative ability.