- Home

- About Us

- Blog

- Capabilities

Sub-Processes

Plastic Materials

Processes Available

Post Processing

- Contact Us

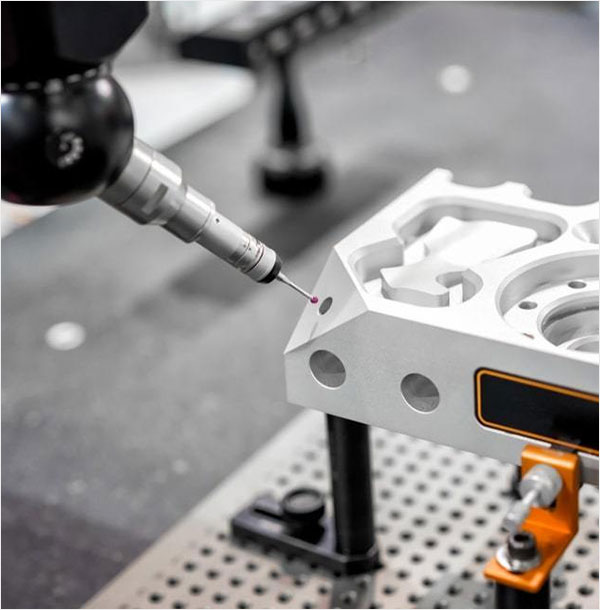

supports coordinate measuring machine high-precision service and form evaluation for precision products.

In this service, we measure dimensions for drawings and 3D models using a CNC coordinate measuring machine, and then we transmit the measurement data using output techniques including inspection tables and model matching. Regardless of the business, we can handle a wide range of products, from small parts to giant products, and provide precise measurement data for varied objects. To be able to deliver the best measurement results for the measured object, evaluation content, and needed accuracy, we have a vast range of measuring machines of various sizes and manufacturers, as well as collation software.

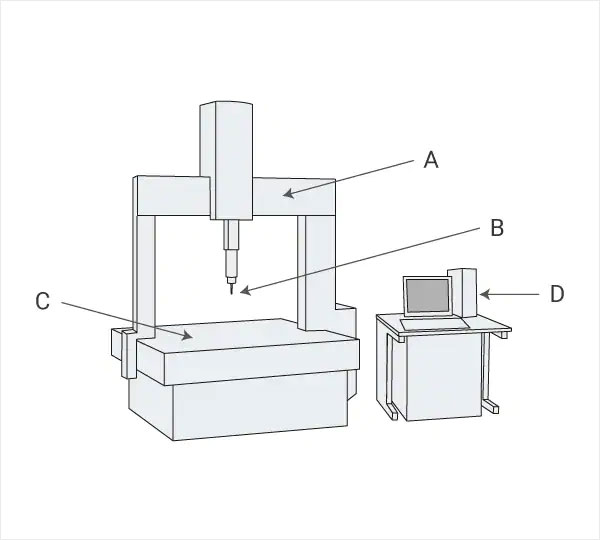

CMM is short form of coordinate measuring machine, generally applies a contact to an object on the stage, acquires three-dimensional coordinates from the length, width, and height, and obtains the dimensions, positional relationship, contour shape, geometrical tolerance, etc. of the object. It is a stationary measuring machine that can measure with high accuracy. In addition to being able to record measurement data of objects, it is also possible to calculate various values by various calculations.

In addition, with the recent spread of 3D printers, it is also being used for rebus engineering, which measures the 3D dimensions of existing parts and standard parts and produces prototypes with 3D printers based on the data.

The information of the measurement points by the CMM is recorded as 3D coordinates (X, Y, Z). By combining the coordinate information, you can create a two-dimensional or three-dimensional geometric element.

The combination of these factors measures dimensions, tolerances, and so on.

The names and classification methods of coordinate measuring machines differ depending on the type of measuring device and the measuring method.

・ Classification by installation method

・ Classification by appearance

・ Classification by measurement method

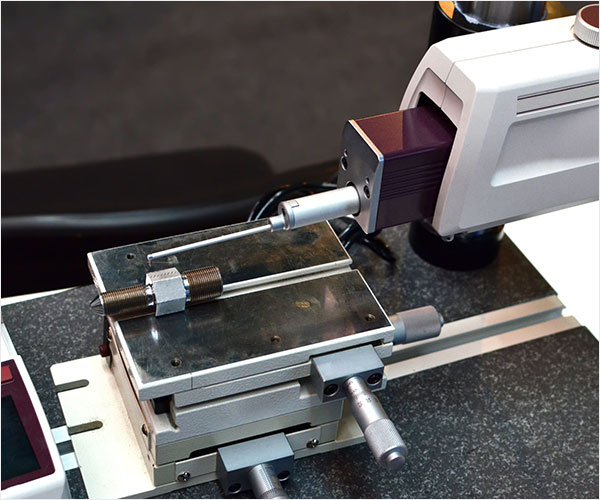

The object is placed on the object to be measured for 5 hours or more in advance and allowed to reach room temperature (generally 20 ° C) to prevent errors due to thermal expansion.

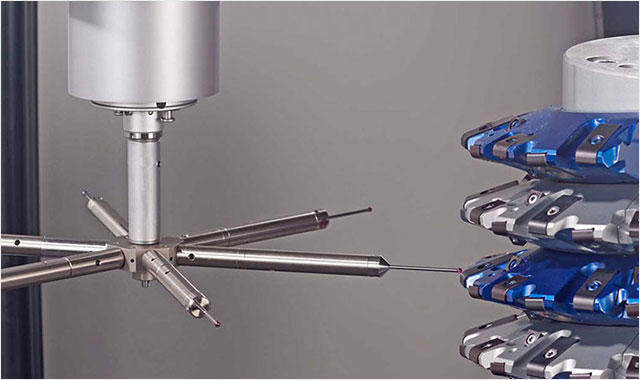

Based on our specialized knowledge, we perform initial setting (calibration) of the probe and perform measurement according to the handling procedure. The measured data can be imported into a personal computer and used as data such as 3D-CAD.

1.Stylus Calibration

2.Handling Precautions

3.Equipment Maintenance

4.User training