Connecting a CNC (Computer Numerical Control) machine to a computer is essential for precise and automated machining. This guide will help you understand how to connect a CNC machine to a computer. Let’s get started!

What is a CNC Machine?

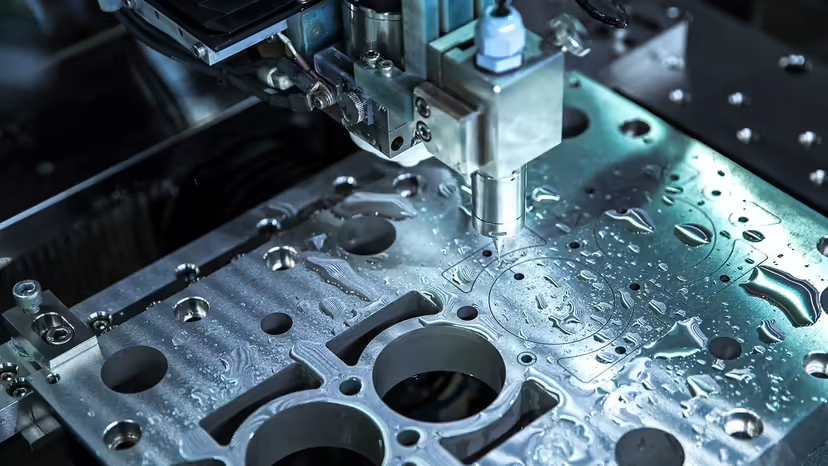

In the first place, we should discuss what a CNC machine is. CNC machines are instruments that can cut, shape, and drill materials. They are constrained by a Computer. This makes them exceptionally exact and quick. CNC machines are used in manufacturing plants, studios, and even by specialists at home.

Why connect a CNC Machine to a Computer?

Interfacing a CNC machine with a Computer permits you to control it. You can make plans on the Computer and afterwards tell the CNC machine to make those plans. This cycle is called CNC programming. It makes working with the machine simpler and more tomfoolery.

Tools You Need

To connect a CNC machine to a computer, you need some tools and software. Here is a list:

- CNC Machine: The machine you want to connect.

- Computer: A desktop or laptop.

- CNC Controller: A device that acts as a bridge between the computer and the CNC machine.

- Cables: Usually USB, Ethernet, or Parallel Port cables.

- Software: CNC software like GRBL, Mach3, or Easel.

How to connect CNC machine to computer: Step-by-Step

We should separate the interaction into simple tasks.

Check Your CNC Machine

To begin with, check your CNC machine. Check out at the ports and connectors. A few normal ports are USB, Ethernet, and Equal Port. Knowing the kind of port will assist you with picking the right link.

Choose the Right Cable

Then, pick the right link. If your CNC machine has a USB port, use a USB link. Assuming it has an Ethernet port, use an Ethernet link. Ensure the link is sufficiently long to reach from the CNC machine to the Computer.

Connect the Cable to the CNC Machine

Presently, associate the link to the CNC machine. Plug one finish of the link into the CNC machine’s port. Ensure it fits cozily.

Connect the Cable to the Computer

Then, associate the opposite finish of the link to the Computer. Once more, ensure it fits well.

Install CNC Software

Presently it is the ideal time to introduce the CNC programming on your Computer. Here are a few famous decisions:

- GRBL: Free and open-source programming for specialists.

- Mach3: Paid programming with loads of elements for cutting-edge clients.

- Easel: Simple to-involve programming for fledglings.

Download the product from the web. Adhere to the directions to introduce it on your Computer.

Configure the Software

In the wake of introducing the product, you want to arrange it. This implies positioning it to converse with your CNC machine. How it’s done:

- Open the Product: Begin the CNC programming on your Computer.

- Select the Port: Pick the port where your CNC machine is associated. This may be USB, Ethernet, or Equal Port.

- Set Boundaries: Enter the right boundaries for your CNC machine. These incorporate speed, feed rate, and hub settings. You can find these boundaries in your CNC machine’s manual.

Test the Connection

Presently it is the ideal time to test the association. This is what to do:

- Make a Straightforward Plan: use the CNC programming to make a basic plan. This could be a square, a circle, or even your name.

- Send the Plan to the CNC Machine: Snap the “Send” or “Run” button in the product. This sends the plan to the CNC machine.

- Watch the CNC Machine: Check whether the CNC machine begins working. Assuming it does, you have effectively associated it with the Computer.

Troubleshoot if Needed

If the CNC machine doesn’t work, simply sit back and relax. Here are some investigating tips:

- Take a look at Associations: Ensure all links are connected accurately.

- Look at Programming Settings: Guarantee the product settings match your CNC machine’s boundaries.

- Restart Everything: At times, restarting the Computer and CNC machine makes a difference.

Final Words

Interfacing a CNC machine with a Computer could appear to be hard, yet all at once it’s not. By following these straightforward advances, you can do it without any problem. Make sure to take a look at your machine, pick the right link, introduce the product, and test the association. With your CNC machine associated with the Computer, you can make astounding plans and rejuvenate them.

FAQs

Can I connect any CNC machine to a computer?

Most CNC machines can be associated with a Computer. Take a look at the machine’s manual no doubt.

What if my CNC machine does not have a USB or Ethernet port?

Some more seasoned CNC machines use Equal Ports. You could require an exceptional link or connector.

Is the software free?

Some CNC programming is free, such as GRBL. Others, such as Mach3, could cost cash.

Can I use a tablet or phone instead of a computer?

It’s ideal to use a Computer since it has serious handling power and better programming support.

Do I need internet access to connect my CNC machine?

You want web admittance to download the product. From that point onward, you needn’t bother with the web to associate the CNC machine with the Computer.