Yes, a CNC machine can cut metal! CNC (Computer Numerical Control) machines are astounding apparatuses that can cut, shape, and make different things from metal. We should jump into how they work, their advantages, and a few normal inquiries individuals have about them.

What is a CNC Machine?

A CNC machine is a PC-controlled device used to move devices and hardware with incredible accuracy. It tends to be customized to play out many undertakings, like cutting, penetrating, and processing. The PC sends directions to the machine, telling it precisely where to move and what to do.

How Does a CNC Machine Cut Metal?

CNC machines can cut metal using various devices, similar to drills, machines, and designs. Here is a straightforward breakdown of how it functions:

- Design the Part: First, you design the part you need to make on a PC using computer-aided design (PC Supported Design) software. This design goes about as an outline for the CNC machine.

- Program the Machine: Next, the computer-aided design configuration is changed over into a CNC program. This program advises the machine how to move, where to cut, and how quickly to go.

- Set Up the Machine: After the program is prepared, you set up the CNC machine. This includes getting the metal piece set up and appending the right cutting device.

- Begin Cutting: At long last, you start the machine, and it adheres to the customized guidelines to exactly cut the metal.

Types of Metals CNC Machines Can Cut

CNC machines can cut many sorts of metals, including:

- Steel: Solid and sturdy, steel is regularly used in development and assembling.

- Aluminum: Lightweight and simple to work with, aluminum is used in aviation and auto enterprises.

- Metal: Known for its low erosion, metal is much of the time used in plumbing and electrical applications.

- Copper: Astounding for electrical wiring because of its high conductivity.

- Titanium: Very impressive and lightweight, titanium is used in aviation and clinical devices.

Advantages of Involving CNC Machines for Cutting Metal

Using CNC machines for cutting metal offers many benefits:

- Accuracy: CNC machines can make exceptionally exact cuts, which is significant for making itemized parts and parts.

- Proficiency: These machines can work consistently without getting worn out, prompting quicker creation times.

- Consistency: CNC machines can deliver different indistinguishable parts, guaranteeing consistency and quality in assembling.

- Complex Plans: CNC machines can deal with many-sided plans that would be troublesome or difficult to accomplish manually.

- Security: Robotizing the cutting system lessens the gamble of mishaps and wounds.

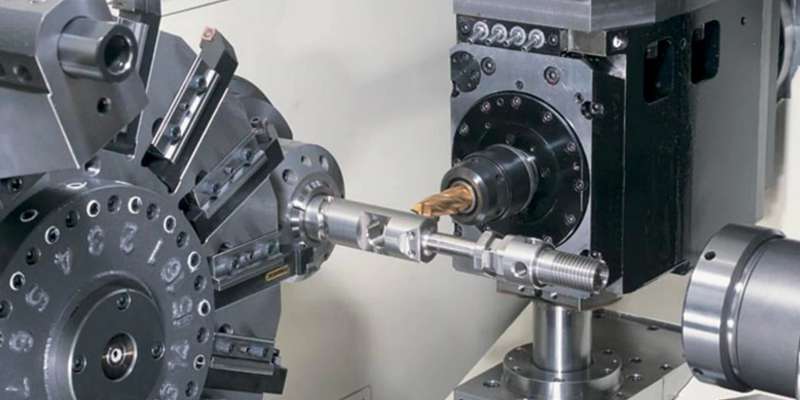

Common CNC Machine Tools for Cutting Metal

A few devices are used with CNC machines to cut metal, including:

- End Factories: used for cutting spaces, profiles, and unpredictable shapes.

- Bores: used for making openings in metal.

- Machine Devices: used for turning and molding metal on a machine.

- Plasma Cutters: use a high-temperature plasma bend to slice through metal.

- Laser Cutters: use an engaged laser bar to cut metal with high accuracy.

Setting Up a CNC Machine for Metal Cutting

Setting up a CNC machine for cutting metal includes a few stages:

- Secure the Metal: Ensure the metal piece is safely attached to the machine bed to forestall development during cutting.

- Pick the Right Instrument: Select the suitable cutting device for the sort of metal and the ideal cut.

- Adjust the Machine: Guarantee the machine is appropriately aligned for precision. This might include setting the zero point and checking apparatus balances.

- Load the Program: Burden the CNC program that contains the guidelines for cutting the metal.

- Test the Arrangement: Run a test cut on a piece of metal to confirm everything is set up accurately.

Where to find the best CNC machine?

Looking for the best CNC machine? Take a gander at Junying, the top CNC machine supplier. They offer first-rate machines ideal for cutting metal. Junying’s CNC machines are strong and capable, making them a phenomenal choice for any errand. Also, their client help is surprising. Visit Junying’s site to examine their decision and find the ideal CNC machine for your necessities. Shop with conviction at Junying, where quality meets execution!

Final Words

CNC machines are incredible assets that can cut metal with accuracy and effectiveness. From basic shapes to complex plans, they offer vast opportunities for making top-notch metal parts. By understanding how they work and following endorsed strategies, you can achieve wonderful results in CNC metal cutting.

FAQs

How long does it take to cut metal with a CNC machine?

The time it takes to cut metal with a CNC machine depends upon the multifaceted design of the arrangement, the kind of metal, and the machine’s speed. Fundamental cuts can require several minutes, while complex plans could require a couple of hours.

Can a CNC machine cut all types of metal?

While CNC machines can cut many sorts of metal, a few metals might require specific devices or settings. It’s essential to pick the right apparatuses and settings for the particular metal you’re working with.