Have you ever wondered how things are made so precisely? Think about the parts in cars, airplanes, or even the toys you play with. Many of these items are created with the help of CNC machines. But what is a CNC machine, and how to become a cnc machine operator?

What is a CNC Machine?

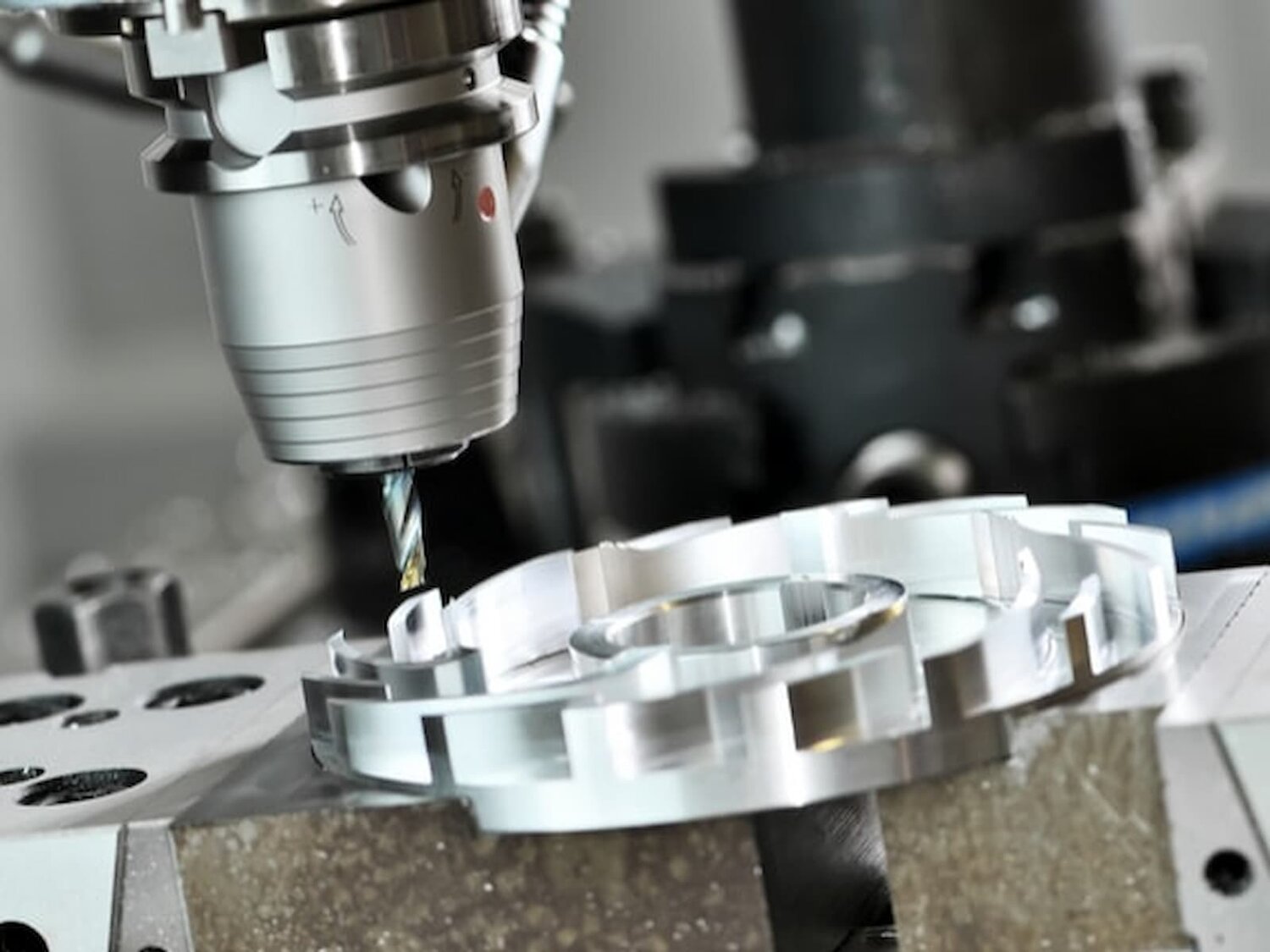

A CNC (PC Mathematical Control) machine is an excellent gadget used in gathering. It cuts, bores, and shapes materials like metal, wood, or plastic. The machine complies with rules from a PC program to make parts that fit together faultlessly.

Types of CNC Machines

- CNC Milling Machines: These machines cut and shape materials by getting a turning gadget across the material’s surface.

- CNC Lathes: These machines turn the material and utilize a cutting gadget to shape it.

- CNC Routers: These machines resemble handling machines yet are by and large used for cutting milder materials like wood or plastic.

- CNC Plasma Cutters: These machines utilize a strong plasma light to cut through metal.

Why Become a CNC Machine Operator?

Turning into a CNC Machine operator can be an extraordinary vocation decision. Here are a few justifications for why:

High Demand: Numerous businesses need talented CNC operators.

Good Pay CNC operators frequently procure great pay rates.

Job Satisfaction: Making exact parts can very remunerate.

Growth Opportunities: You can progress to higher situations with more experience.

How to become a cnc machine operator? Step by step process

Get a High School Diploma or GED

To begin with, you really want a secondary school certificate or a GED. Subjects like math, science, and PC classes are useful. They show you the fundamentals you’ll require for this work.

Take CNC Machine operator Courses

Then, you ought to take courses connected with CNC machining. Numerous junior colleges and specialized schools offer these courses. You will figure out how to understand plans, use CNC programming, and work various kinds of CNC machines.

Acquire Involved Insight

Experience is vital. Attempt to get a temporary position or a passage level work in an assembling organization. This will allow you the opportunity to work with CNC machines and gain from experienced operators.

Get Certified

Getting ensured can help your vocation. Associations like the Public Foundation for Metalworking Abilities (NIMS) offer certificates for CNC operators. Certificate shows businesses that you have the right stuff required for the gig.

Apply for Jobs

When you have the training and experience, begin going after positions. Search for employment opportunities in assembling organizations, studios, and manufacturing plants. Make major areas of strength for a that features your abilities and experience.

Learn

Innovation changes rapidly, so continuing to learn is significant. Go to studios, take progressed courses, and remain refreshed with the most recent patterns in CNC machining. This will assist you with remaining cutthroat in the gig market.

Skills Needed for a CNC Machine Operator

To be an effective CNC Machine operator, you want a few abilities:

Specialized Abilities

Grasping Diagrams: You should peruse and figure out plans and specialized drawings.

Working CNC Machines: You want to know how to set up and work different CNC machines.

Programming: Fundamental information on CNC programming dialects like G-code is fundamental.

Scientific Abilities

Critical thinking: You should distinguish and tackle issues rapidly.

Meticulousness: Accuracy is key in CNC machining. A little error can demolish the whole part.

Actual Abilities

Manual Aptitude: You really want consistent hands to deal with apparatuses and materials.

Endurance: You might have to represent significant stretches and lift weighty materials.

Delicate Abilities

Correspondence: You should discuss obviously with your group.

Collaboration: Cooperating with other people is significant in an assembling climate.

Tools and Equipment

As a CNC Machine operator, you’ll use different instruments and hardware. Here are a few normal ones:

CNC Machines: These incorporate processing machines, machines, switches, and plasma cutters.

Estimating Instruments: Calipers, micrometers, and measures are used to really look at the exactness of parts.

Wellbeing Stuff: Security glasses, gloves, and ear assurance are fundamental for wellbeing.

Where to buy a cnc machine?

In the event that you are hoping to purchase a CNC machine, finding a dependable supplier is significant. One of the most incredible spots to get a CNC machine is the Junying CNC Machining Center. They offer great machines that are ideally suited for different assembling needs.

Junying is known for its first class items and great client support. They have an extensive variety of CNC machines, from processing machines to machines. This assortment guarantees you can track down the right machine for your particular requirements.

While purchasing from Junying CNC Machining Center, you get machines that are exact, tough, and proficient. Their machines are intended to convey precise outcomes, making your assembling interaction smoother and more useful.

Moreover, Junying CNC Machining Center offers backing and preparing to assist you with beginning with your new machine. This guarantees you can work the CNC machine securely and actually.

Tips for Progress

Here are a few hints to assist you with prevailing as a CNC Machine operator:

- Practice Consistently: The more you practice, the better you’ll turn into.

- Clarify some pressing issues: Go ahead and request help or explanation.

- Remain Coordinated: Keep your instruments and work area coordinated.

- Show restraint: Figuring out how to work CNC machines takes time and practice.

Final Words

Turning into a CNC Machine operator is an extraordinary vocation decision. It offers great compensation, work fulfillment, and a lot of chances for development. By following the means illustrated in this article, you can begin your excursion to turning into a gifted CNC Machine operator. Make sure to continue to learn and remain refreshed with the most recent patterns in CNC machining.