Garolite G-10

At a glance

| Processes | Lead Time | Colors | Tolerance | Price | Applications |

|---|---|---|---|---|---|

| CNC Mill CNC Lathe | As fast as 3 days | Black, neutral matte finish | With drawing: as low as +/- 0.005 mm No drawing: ISO 2768 medium | $ | Impact-resistant applications, production-like parts (pre-injection molding) |

About the Material

Garolite G-10 (also known as phenolic and epoxy-grade industrial laminate) is a composite material with a low coefficient of thermal expansion. Additionally, it does not absorb water and is an excellent insulator, which makes it really useful for electronics applications.

Material Properties

Tensile Strength | Elongation at Break | Hardness | Density | Maximum Temperature | McMaster Part Number |

|---|---|---|---|---|---|

| 35,000-50,000 PSI | Not rated | Rockwell M110 | 0.069 lbs / cubic in | 265° F | 8667k151 |

Material Finish

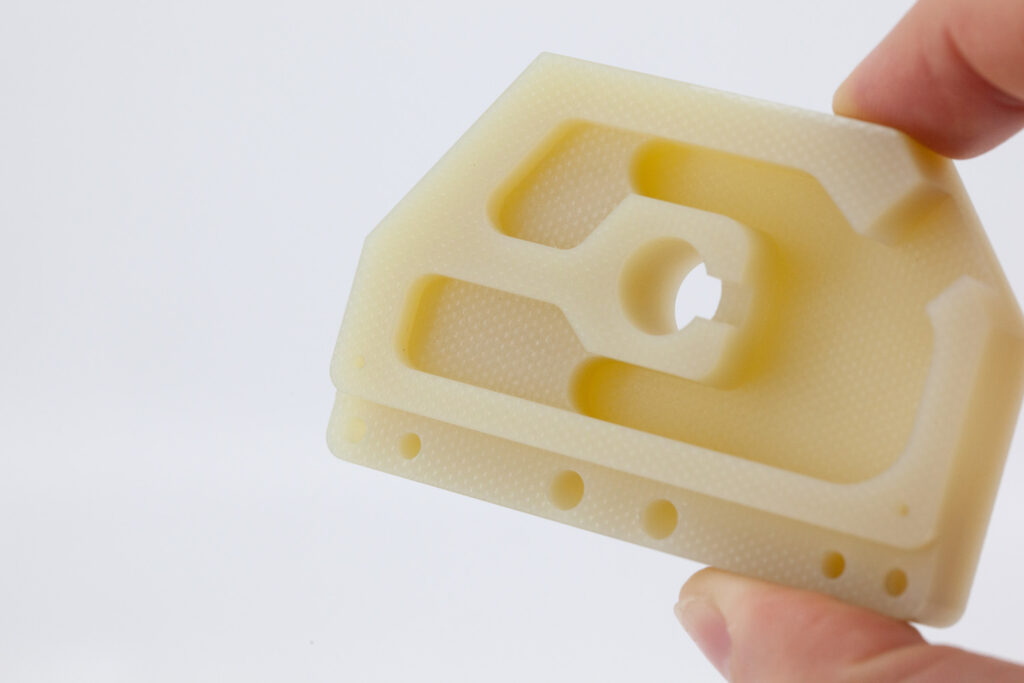

Garolite G-10 comes in a variety of mostly opaque colors (such as green and yellow, depending on availability). It is smooth and has a matte surface when machined. Additionally, Garolite G-10 can be machined to a variety of surface roughnesses.

Design Recommendations

Tensile Strength | Elongation at Break | Hardness | Density | Maximum Temperature | McMaster Part Number |

|---|---|---|---|---|---|

| 35,000-50,000 PSI | Not rated | Rockwell M110 | 0.069 lbs / cubic in | 265° F | 8667k151 |

Garolite G-10 FAQs

ABS plastic is a low-cost engineering plastic, widely used for pre-injection molding prototypes. CNC machined ABS is a great option for production-like parts, where detail and mechanical properties are important.

Depending on the desired outcome for the project, ABS plastic can either be cut or engraved using CNC milling.

ABS plastic is an excellent choice for general purpose prototyping, pre-molding prototypes, parts that will receive impact and require toughness, or when low cost is desired.

CNC (Computer Numerical Control) machining is an automated, subtractive manufacturing process where a CNC machine is controlled with a set of commands that, when followed, will produce a part. CNC operators create….

Too Tight or Perfect Fit? When to Use Press Fits in Assemblies

example dowel pin interference fit table