A CNC milling machine: what is it?

This is a unique machine used for shaping and cutting materials such as plastic, wood, and metal. The acronym CNC denotes Computer Numerical Control. This indicates that a computer aids in machine control to ensure precise cutting. Because they can create very detailed pieces, they are extremely important in manufacturing. They are also fast and precise at it.

How CNC Milling Devices Operate

Three key stages are involved in the operation of a CNC milling machine. Initially, a computer is used to create a design using specialized software. This graphic design accurately depicts the appearance of the component. This design is then translated into a machine-understandable set of instructions. Lastly, the machine moves a cutting tool around the material using these leads. To mold the material into the desired form, the tool may move up, down, left, and right.

Which kind of CNC milling machines are most common?

The machine kinds are each used for a different range of tasks and complexity levels. Among the devices are:

- Vertical milling machines

- A vertically oriented spindle is a feature of vertical milling machines. It is known as a vertical machining centre (VMC). They are often used for various milling tasks because of their versatility. Their precision and simplicity of usage have made them well-liked.

- Vertical mills include turret mills as a subtype. Within it, the table moves both horizontally and longitudinally. And the spindle may move up and down.

- Horizontal Machining Centers (HMC):

Horizontal milling machines Their spindle is positioned horizontally. They improve chip evacuation and are used for tougher, heavier milling jobs.

- Universal milling machines:

support vertical and horizontal milling activities. They are more adaptable and come with a revolving table for complex tasks.

- Three-Axis Milling Devices:

These devices have three linear axes of motion (X, Y, and Z). For simple operations, these are the most popular and fundamental kinds of machines.

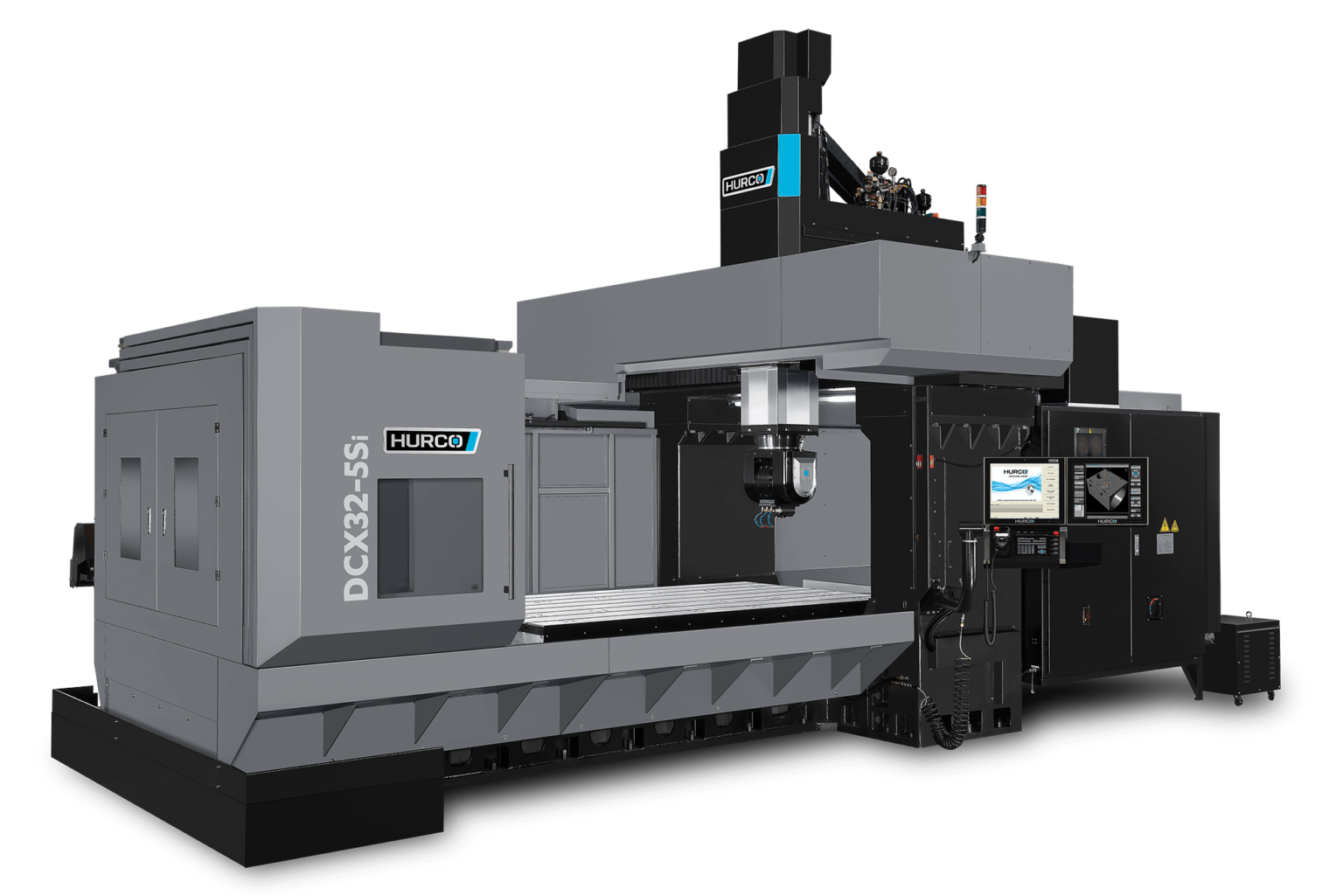

- 5-Axis Milling Machines:

These combine the three linear axes with two extra rotating axes (A and B). Furthermore, it permits machining complicated and complex parts in all directions. The automobile and aerospace sectors often employ them.

These popular machine kinds serve a range of industrial requirements. These include both easy and tough milling jobs. Additionally, they provide varying degrees of capability, adaptability, and accuracy.

CNC Milling Machine Advantages

These machines provide several advantages. They can precisely cut materials as required since they are incredibly accurate. They speed up the work and end the need for humans to do physical labor, increasing their efficiency. Metals and polymers are only two of the various things that these machines can operate with. Once a design is created, it may be repeatedly utilized to produce an identical element.

Use of CNC Milling Equipment

Numerous industries use these machines. Within the automotive sector, auto components are produced. Parts for airplanes are made in aerospace. Small parts for computers and phones are made in the electronics industry. They manufacture precision instruments and equipment for physicians in the medical industry. They are also used to produce molds for metal and plastic components.

How can I get the most information on CNC milling machines?

A clean, spacious place with enough air and easy access to electricity and supplies is ideal. For precise work, light is essential, as is a level, stable platform to maintain stability. Junying maintains a great website dedicated to these machines. Everything is explained understandably and straightforwardly. Junying provides a wealth of helpful information and services. Junying’s website is an excellent resource for learning, regardless of experience level. Moreover, you can maximize the performance of your machine.

FAQs

How is a CNC machine operated?

To begin, you use a computer to create. The design becomes a set of instructions. The machine follows these to cut the material.

What benefits may we expect from CNC machines?

The accuracy of CNC machines is relatively high. They need less physical effort and operate quickly. They can produce the same item again in excellent quality.

In what ways may these machine increase productivity?

CNC devices operate autonomously. It helps to save time and work. They can produce components quickly and continuously.

How can one distinguish between a vertical and horizontal one?

The tool on a vertical machine travels up and down. The tool of a horizontal machine travels sideways. Each works better with a specific cut.

Can these machines produce intricate forms?

Yes, in particular, for 5-axis machines. The tool may be moved in five different ways. It enables them to create very intricate shapes.

How does one program a CNC machine?

Next, CAM software is used to convert the design into instructions. In the end, insert these instructions into the device.

In summary

These incredible instruments are used to create anything from automobiles to medical components. They precisely cut and shape materials by using computer instructions. As a result, it is ideal for contemporary production. These devices aid in the rapid and effective production of high-quality components. It improves and increases the dependability of our regular goods. These devices will remain vital to producing new goods even as technology grows.