- Home

- About Us

- Blog

- Capabilities

Sub-Processes

Plastic Materials

Processes Available

Post Processing

- Contact Us

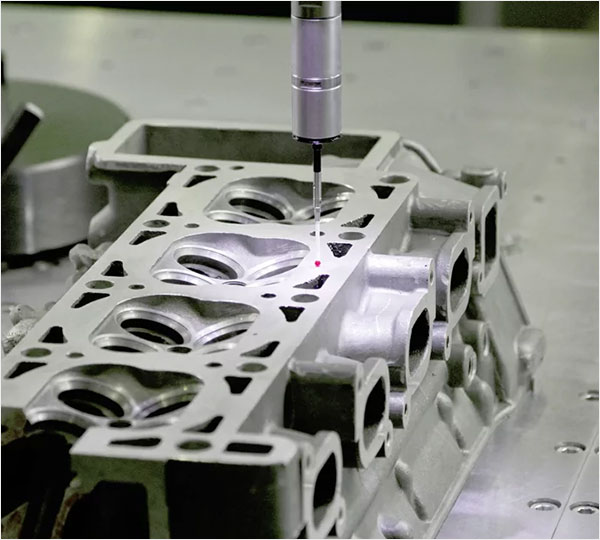

n recent years, with the establishment of ISO, it has become necessary to maintain forms, and the measurement data of parts contributes to the improvement of this quality. The measuring instruments that make full use of the latest measurement technology and the measurement data created by skilled measurement technicians are highly trusted by many users. “Reduce working hours” and “shorten delivery time” are important issues in manufacturing, and this is no exception in the quality control process. Therefore, CMM is widely used for Dimensional Inspection of CNC processed tools ( 2D drawings, 3D Models, master product or tooling).

In this CMM service, CNC’s coordinate measuring machine is used to measure the dimensions of drawings and 3D models, and the measurement data is submitted through output methods such as inspection tables and model matching. We can handle a wide range of products from small parts to large products, and provide accurate measurement data for various objects in various industries. We have a large number of measuring machines and verification software of various sizes/manufacturers, so that we can provide the best measurement results for the measured object, the evaluation content and the required accuracy.

In recent years, the development of 3D printers has improved the accuracy of modeling, and CNC modeling products have begun to be used for various purposes. However, in order to use a model product as a fixture or a final part, it needs to be evaluated to ensure quality, and dimensional inspection is one of the important evaluation items in this evaluation.

For most inspection equipment, there is a means prepared to directly transmit dimensional data to the dimensional inspection report. The transmission of dimensional inspection data greatly contributes to the prevention of erroneous entry mistakes due to manual input, etc., and also contributes to reducing the human stress of the confirmer when checking the dimensional report.

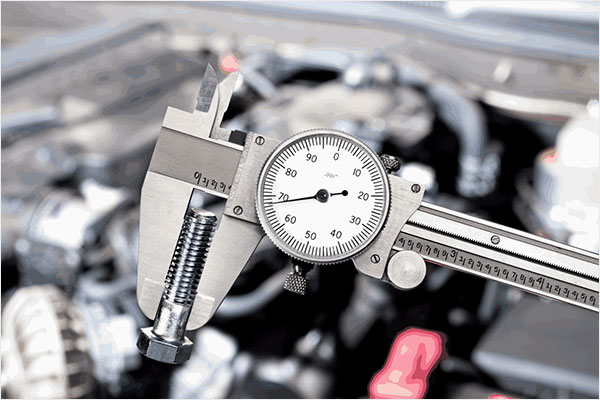

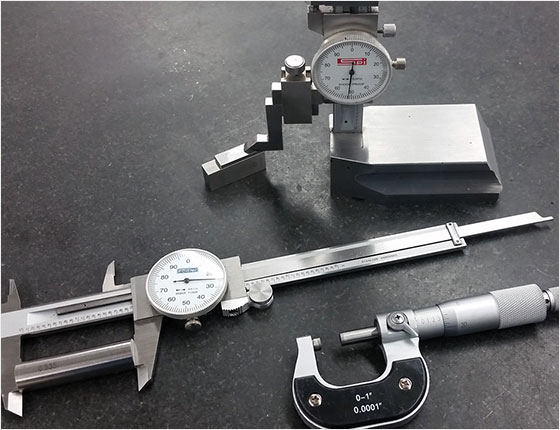

There are roughly two types of dimensional measurement methods, including analog dimensional measurement such as calipers and gauges, and three-dimensional measurement using a portal type or articulated arm type.

Compared to conventional analog dimensional measurement, 3D measurement is an excellent one that can be expected to dramatically improve the process.

Here, we will introduce the know-how of new Coordinate Measuring Machines that can be expected to solve your problems from the basic knowledge of Coordinate Measuring Machines.

CMM is suitable for measuring the dimensions and shape of 3D objects. Coordinate Measuring Machine is performed in the three-dimensional direction (X, Y, Z) using a contact-type measuring machine that takes a coordinate point by bringing a spherical stylus (contactor) attached to the tip of the probe into contact with the product. to hold. It is possible to perform advanced dimensional measurements such as geometric tolerance measurement that cannot be measured with calipers with high accuracy.