In the world of precision engineering, ensuring that every part is manufactured to exact specifications is crucial. One of the key aspects of this process is precision measurement. These tests are essential for testing the accuracy of parts, especially in industries like aerospace, automotive, and electronics, where even the slightest deviation can lead to performance issues. In China, where the manufacturing industry is one of the largest in the world, services like form tracing and roundness testing are in high demand. We’ll explore what these processes are, why they are important, and where you can find circularity testing services providers.

What is Form Tracing and Roundness Testing?

Form tracing is a system used to decide the form or profile of an element to make sure that it fits the layout specs. During this method, the part is cautiously inspected to pick out any deviations from its intended shape. This is particularly crucial for components that need to in shape precisely inner a larger machine. For example, gears, seals, and bearings all require correct profiling to make certain that they paintings easily without causing unnecessary wear or malfunction.

Roundness testing, on the other hand, is targeted at measuring how flawlessly round an aspect is. While many additives have a spherical shape, not all are flawlessly spherical. A small imperfection in roundness can cause problems like uneven put on, terrible overall performance, or maybe failure in certain programs. Geometric accuracy testing includes the usage of specialized equipment to degree the circularity of the element, making sure that it meets the desired tolerances.

Why is Roundness Testing Important in Manufacturing?

Roundness testing out is critical in production due to the fact many elements, in particular those involved in mechanical strategies, depend upon particular spherical shapes for his or her feature. An element that is supposed to rotate without problems, like a shaft or a bearing, wishes to be perfectly round to make sure it operates without issues. If an aspect is even slightly out of spherical, it can cause imbalances, vibrations, and undue pressure, which can fail.

For example, in the car industry, engine additives collectively with pistons, crankshafts, and gears have to be perfectly spherical to ensure they float effectively and do not cause more stress on other additives. In aerospace, the stakes are even higher. Turbine blades, for example, need to maintain their roundness to operate at immoderate speeds and excessive temperatures without risking catastrophic failure.

In addition to mechanical typical overall performance, roundness testing out additionally performs a function in ensuring that components healthy collectively correctly. Many assemblies rely on components being round to fasten securely or rotate easily. A moderate error in roundness can lead to negative assembly or harm for the duration of operation.

For those motives, shape verification in manufacturing is a crucial part of the best manipulation process in production. By ensuring that components are within the precise tolerances, producers can reduce the risk of defects, enhance reliability, and meet industry standards for performance and protection.

Different Parts of Form Tracing and Roundness Testing

Here are some of the maximum common types of elements that advantage from the ones exams:

Automotive Parts: Parts which includes engine additives, gears, pistons, and crankshafts are crucial in ensuring easy operation and sturdiness. If those additives aren’t effectively formed or spherical, the engine must malfunction, primary to inefficiencies or maybe failure.

Aerospace Components: The aerospace industry desires especially high standards for precision and protection. Parts like turbine blades, actuators, and bearings need to fulfill unique roundness and form specs to characteristic at peak overall performance without failure.

Industrial Machinery: Parts like bearings, shafts, and gears are essential in heavy equipment used in production, production, and other sectors. These components ought to hold perfect roundness to ensure clean operation and save you extra wear.

Medical Devices: Devices like syringes, needles, and implants regularly require form tracing and roundness measurement equipment to ensure they meet strict health and protection standards. Even the slightest deviation can result in operational issues or health dangers.

Electronics Components: Many electronic components, including connectors and housings, ought to be produced with high precision to make certain they healthy nicely and characteristic reliably. Small deviations in shape or roundness can result in bad performance or failure.

Reliable Form Tracing and Roundness Testing Services

When looking for dependable form tracing and roundness testing offerings in China, Junying is a top choice. With more than a decade of enjoy in CNC machining quality control, Junying has established itself as a dependable employer for OEM clients. They offer an entire range of services, collectively with CNC machining factors and CNC machining prototypes. This makes them a in reality ideal one-prevent keep for clients who want both the manufacturing and testing of factors.

Junying’s popularity for the top position is based on years of experience in precision engineering. The organisation uses present gadgets for circularity testing services, making sure that each detail is appropriately measured to meet patron specifications. Whether you are in the car, aerospace, clinical, or business sectors, Junying can provide the services you need to ensure your elements are synthesised with precision.

Process of Our Form Tracing and Roundness Testing Service

The process for form tracing and roundness testing at Junying is unique and thorough. Once the elements are geared up for testing, the manner starts.

Initial Inspection

Before testing out, the elements are inspected for any obvious defects or harm. This initial inspection ensures that the elements are in top situation before undergoing any trying out.

Form Tracing

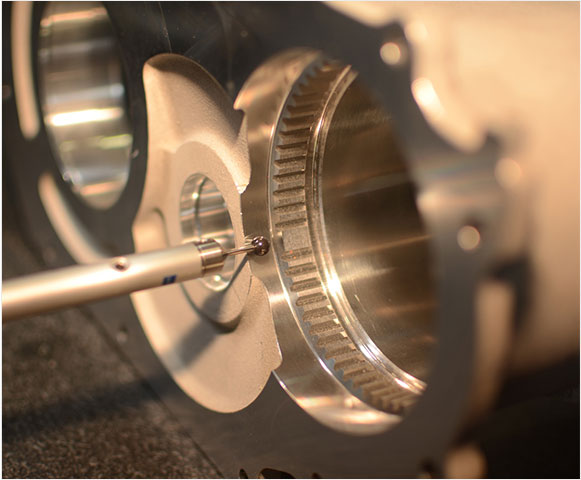

The next step is form tracing, where the profile of the component is measured. Junying uses advanced equipment to hint the form of the part, testing for any deviations from the intended form. This is mainly essential for elements like gears, seals, and different additives that must in shape precisely inside a larger assembly.

Roundness Testing

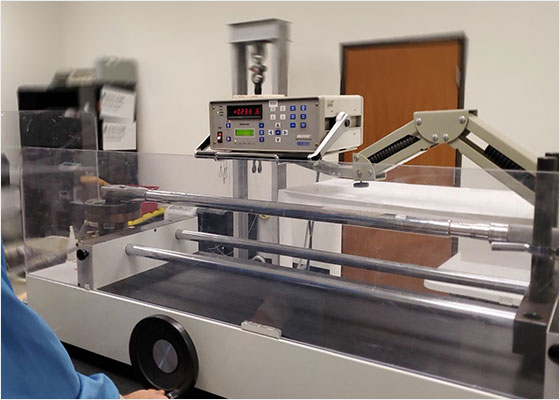

After form tracing, the subsequent step is roundness testing. Junying makes use of specialised roundness testers to degree how round the part is. Even small imperfections in roundness can result in operational troubles, so this take a look at is vital for making sure that the element will perform as anticipated.

Data Analysis and Reporting

Once the tests are completed, the information is analyzed to decide whether the elements meet the desired specs. Junying provides an in-depth file for every component, highlighting any deviations and supplying answers to bring the element within tolerance if important.

Final Adjustments

If any components do not meet the required shape or roundness specs, Junying works with clients to make the vital modifications. This may want to contain extra machining or changes to make certain that the component meets the highest requirements.

Delivery

Once all testing and adjustments are complete, the components are equipped for shipping. Junying guarantees that every component is cautiously packaged and shipped to the client, assembly transport cut-off dates and ensures that the components are geared up to be used in manufacturing.

Final Thoughts

Form tracing and roundness testing are essential processes in production, making sure that parts meet the vital specifications for overall performance and exceptional. These tests are critical for industries inclusive of automobile, aerospace, medical devices, and electronics, in which precision is key to capability and protection. If you’re searching for precision and reliability, Junying is a dependable companion in your profile inspection for parts trying out wishes.