Gear hobbing machines are used to make gears. Knowing their basic parts will enable you to comprehend their goal. There are basically five parts. Each part aids in the gears achieving the proper form. In this book, we will discuss these parts and how they interact. As you gain more knowledge about certain items, you will be able to use and correct them. If you want to learn more, keep reading.

What are the five common elements of a gear hobbing machine?

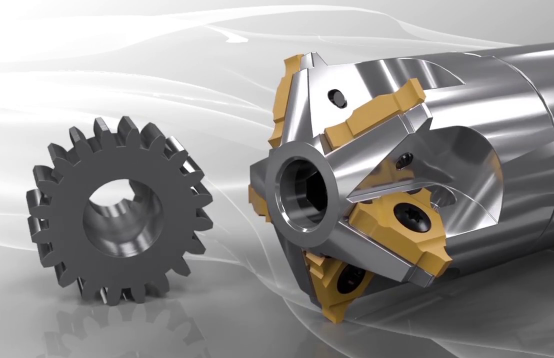

Hob

One vital part of the gear machine is the hob. The gear teeth may be sharpened with the use of this tool. The cooktop resembles a rough side cylinder on wheels. The gear material is cut by its rapid rotation. The hob’s sharp edges create the proper gear for it. The hob must be strong and sharp to produce clean cuts. If your stove is too small, the gears can be cut incorrectly.

Worktable

Orienting the tool in the work area is the first step in the cutting process. It prevents the changing of gears. The worktable is movable and slides to many locations. The hob cuts exactly by adjusting the gears. You may adjust the height and tilt of the worktable to get the perfect position. Good gear production requires a robust workstation.

Spindle

The hob is being held and turned by the machine’s wheel. It details the pace at which the hob rotates. The spindle should be robust and very straight. The hob must be turned easily and exactly. The shaft’s speed directly affects the gear’s capacity to cut hobs. The hob can’t cut the gear exactly unless the wheel is damaged.

Tailstock

The end of the gear cutting is supported by the tailstocks. This indicates that the gear won’t sway or move. Tailstock customization enables the fitting of gears with varying diameters. The apparatus maintains its position so well. Cutting the gear exactly relies on this help. The tailstock aids in preventing incorrect cutting and gear changing.

Control System

The computer cannot function without the operating system. The machine runs because of it. It determines both the most worktable movement and the most hob speed. He makes it easier for the operator to adjust the machine for different types of gear. The machine’s many parts work in perfect harmony with each other thanks to it. It is beneficial that the gear cuts be the right size and form.

Why should I know about the parts of the gear hobbing machine?

The functions of each part in a gear machine must be understood. The machine could be visible to you. You could discern the functions of each element. This method makes it easier to identify and address issues promptly. Minimizing harm ensures your safety. It will be easier for you to operate the tool more rightly if you understand its basics. Both your self-worth and the frequency of your errors will improve. Whether you are a student or an employee, these numbers may be useful. It is always helpful to perform really well.

Where should I go for the gear hobbing machine?

Junying is a great choice for you if you need a gear-honing machine. Using their page is second nature. They’re surrounded by options. Each of them offers information and photographs that are really clear. You can get durable and strong products on this site. If you need help, their customer care is also incredibly helpful. Regardless of your level of skill, you may find out the perfect one here.

How do I take care of the gear hobbing machine?

Your gear machine needs your undivided attention. First, clean it of any dust or debris that may have accumulated on it. Regularly check the oil level and add extra as necessary. Lubricate the moving parts to keep them in good condition. Verify that every fastener is secure. Look for any outdated or faulty components and fix them if they are vital. Be careful not to abuse the device. Maintaining your tool on a regular basis can help it operate better and last longer.

At the bottom line,

It is quite helpful to understand the five major parts of a hobbing machine. These include the wheel, the hob, the worktable, and the cutter, among others. Every tool is available for viewing on the workstation. It adopts the cutter’s form. The blade is driven by the wheel. The gear teeth are sunk by the hob. The gear is driven by the tailstock. Knowing these parts will enable you to operate the tool securely and correctly. Also, troubleshooting and keeping the equipment working well.