Gear hobbing is essential in production industries, mainly for creating gears in diverse machines. Learn about gear hobbing, how it works, its advantages, its applications, and China’s most popular CNC gear manufacturing company.

What is Gear Hobbing?

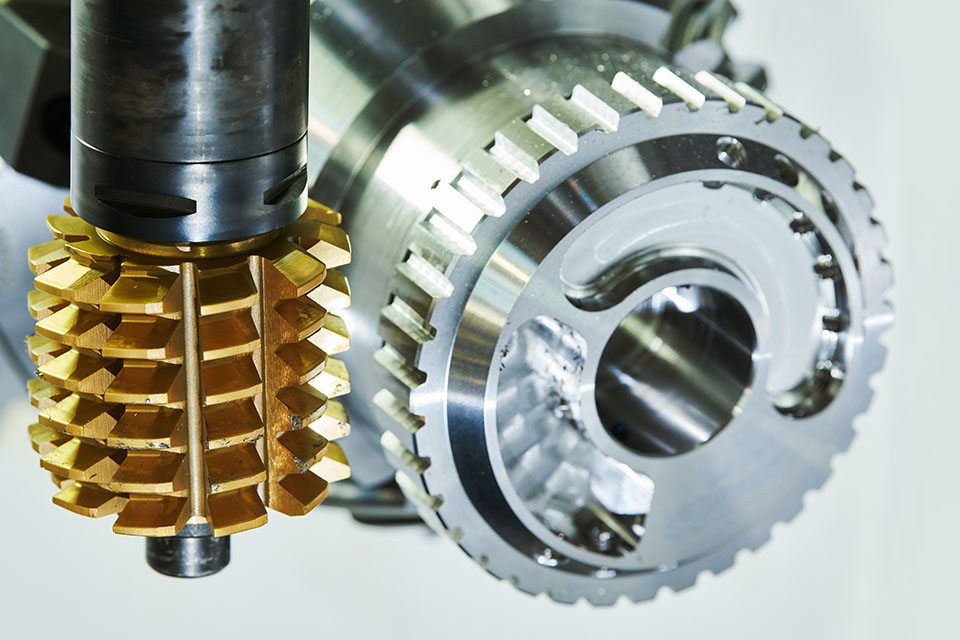

Gear hobbing is a machining system for cutting equipment teeth. It is one of the most efficient methods for developing unique, uniform gears. The process uses a rotating hob to form the gear teeth into the favored size and shape. This method is widely used in industries where gears are critical, including car, aerospace, and production. Companies can produce exquisite gear quickly and cheaply by using precision gear cutting.

How Does a Gear Hobbing Machine Work?

A gear hobbing device uses a rotating device known as a hob. The gear is clean, and the base fabric from which the gear enamel is reduced is fixed on a spindle. The hob, a specialized cutting device, is aligned with the gear blank to ensure particular reduction. Both the hob and the equipment clean rotate at unique speeds. Following the programmed specs, the hob cuts into the blank to create a tooth. This system is non-stop and repeats until all enamel is cut into the gear blank. Gear hobbing machines are extraordinarily particular and may manage even complicated equipment designs. Programmable capabilities allow customization to meet precise manufacturing requirements.

Benefits of Gear Hobbing

Gear hobbing offers numerous advantages, making it a popular equipment production method. One of the main advantages is its performance. The process is rapid and can generate more than one gear quickly. It also guarantees precision, essential for uniform and accurate gear teeth. This stage of precision complements the performance and reliability of the gears.

Tool hobbing is also versatile, as it can create specific gears, including spur gears, helical gears, and splines. This cost-effective technique reduces fabric wastage, making it best for mass production. It is also scalable, allowing manufacturers to handle small—to huge-scale initiatives easily. These advantages make equipment hobbing the desired method for industries requiring perfect gear.

Gear Hobbing Applications

Gears are crucial in transferring motion and power, making gear hobbing an essential process in many industries. The automotive industry uses tool hobbing to manufacture gears for engines, transmissions, and guidance systems. The aerospace enterprise is based on gear hobbing for developing gears used in plane engines and manipulating structures. This technique is crucial for generating gears for heavy systems, including cranes, loaders, and excavators in the equipment region. Robotics additionally depends on automotive gear production for unique gears used in robot fingers and automation structures. Electrical equipment, automobiles, and mills often require synthetic gears through hobbing. Even the clinical field benefits from this method, as high-precision gears are essential in clinical gadgets like surgical equipment. From simple applications to advanced technology, helical gear hobbing supports various industries.

Which is the Best Gear Hobbing Services Provider in China?

Regarding gear hobbing services in China, Junying stands proud to be one of the quality providers. With decades of experience in CNC production, Junying offers first-rate offerings tailor-made to consumer wishes. Junying has hooked up recognition for excellence by combining advanced technology with skilled craftsmanship. Their commitment to turning in precision and exceptional has made them a dependent call inside the enterprise.

Why Choose Junying?

Junying has over ten years of expertise in CNC machining and gear production. They use hundreds of state-of-the-art machines, including CNC machining facilities, lathes, and specialized Industrial gear machining. This tremendous array of gadgets lets them handle initiatives of various complexities. Junying affords a one-stop carrier, imparting answers from prototypes to mass manufacturing. This guarantees a continuing manufacturing procedure for OEM clients. The corporation’s crew includes skilled engineers, operators, and inspectors who paint collaboratively to fulfill exact specifications. Junying’s excessive requirements are maintained through rigorous satisfactory tests, which include ultrasonic cleaning and advanced checking out. These measures make sure that every product is terrific and meets patron expectancies.

Jurying’s CNC Machining Capabilities

Junying’s capabilities include the manufacturing of CNC machining parts and prototypes. Their custom parts are made with precision and speed, catering to the specific desires of their clients. High-nice prototypes are also furnished, permitting customers to check and validate their designs earlier than full-scale manufacturing. Junying’s complete technique to manufacturing, blended with their willpower to satisfaction, makes them a dependable associate for Spur gear fabrication and CNC machining services.

FAQs approximately Gear Hobbing Services

What is gear hobbing?

Gear-hobbing is a precision machining procedure for cutting equipment teeth. It is crucial for creating top-notch, uniform gears for green movement and machine electricity transfer.

What are the principal benefits of tool hobbing?

Gear hobbing is fast, precise, and cost-effective. It reduces fabric waste and can produce numerous gears, making it ideal for mass production in industries such as automobile and aerospace.

Why is Junying considered a top gear hobbing carrier company in China?

Junying is famous for its advanced CNC technology, skilled crew, and many years of enjoyment. They offer complete answers, from prototypes to mass manufacturing, ensuring fantastic gears for distinctive packages.