Looking for a 3D CNC milling service that delivers precision results without breaking the bank? Look no further! In this blog post, we’ll introduce you to a high-quality 3D CNC milling service that will leave you saying, “Wow, I can’t believe it’s not magic!” We’ll dive into the benefits of using this service, the cutting-edge technology they use, and why precision is their middle name. So buckle up and get ready to be amazed by the world of 3D CNC milling!

What is 3D CNC Milling Service and how does it work?

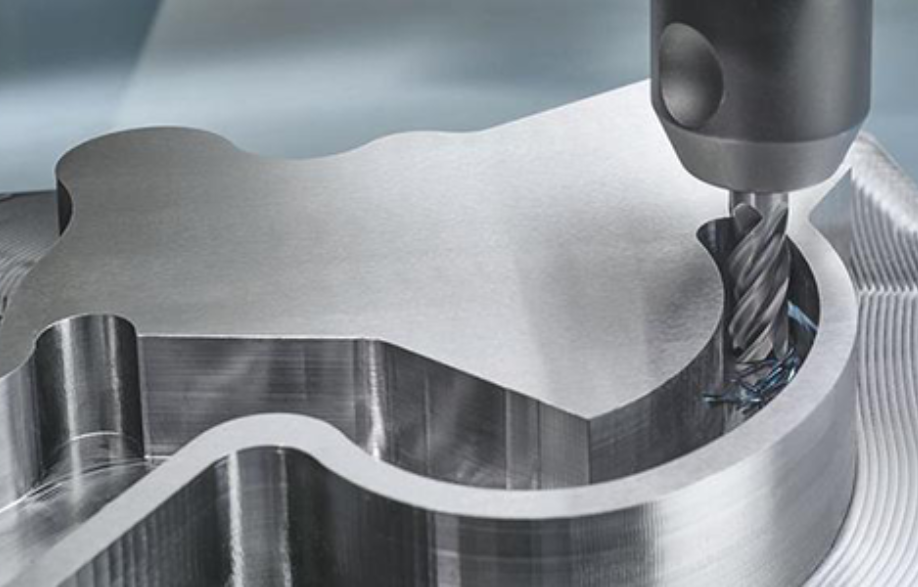

3D CNC Milling is an advanced manufacturing process that allows for the creation of highly precise and complex parts or prototypes. Using computer-aided design (CAD) software, a 3D model of the desired object is created. This digital model is then translated into machine code, which guides the CNC milling machine in cutting and shaping the material.

The CNC milling machine operates by removing excess material from a solid block or billet, using rotating cutting tools. These tools move along multiple axes to shape the material according to the programmed specifications. The result is a precisely machined part with intricate details and high accuracy.

The process begins with the design phase, where a CAD model of the desired object is created. This model can be either custom-designed or obtained from an existing file. Once the design is finalized, it is converted into machine-readable code using CAM (computer-aided manufacturing) software.

Understanding the importance of precision in CNC Milling

Precision is of utmost importance in the field of CNC milling. The success and effectiveness of the process depend on the ability to accurately reproduce the desired shape and dimensions of the object being created. This precision ensures that the final product meets the required specifications and functions as intended.

A high level of accuracy is achieved through several factors. Firstly, the CAD software allows for detailed designing, ensuring that every dimension and feature is measured and accounted for. This ensures that the object’s digital model accurately represents its real-world counterpart.

The Benefits of using a high-quality 3D CNC Milling Service

Using a high-quality 3D CNC milling service offers several benefits. Firstly, it allows for the production of complex and intricate parts with a high level of precision and accuracy. The advanced technology and machinery used in these services ensure that even the most intricate details can be reproduced faithfully.

Another advantage is the ability to work with a wide range of materials. Whether it’s metals, plastics, or composites, a reputable CNC milling service can handle various materials with ease, allowing for versatility in manufacturing.

Furthermore, utilizing a professional CNC milling service saves time and resources. The expertise and experience of these professionals ensure that the milling process is efficient and optimized, resulting in reduced lead times and minimized wastage of materials. This not only improves productivity but also helps to control costs.

How to get Started with a 3D CNC Milling Service

To get started with a 3D CNC milling service, the first step is to identify your requirements and find a reputable service provider. Look for a company that has a proven track record of delivering high-quality results and has expertise in handling the specific materials you require.

Once you have selected a CNC milling service, communicate your project details, including design files, material specifications, and required quantity. The service provider will review your requirements and provide you with a quote and timeline for completion.

Tips for Optimizing Your Designs for CNC Milling

When optimizing your designs for CNC milling, there are a few key tips to keep in mind. First, it is important to design your parts with manufacturability in mind. This means considering the limitations and capabilities of the CNC milling process and designing parts that can be easily machined.

Another tip is to minimize the use of sharp corners and complex geometries. These features can increase the machining time and may result in tool breakage or poor surface finish. Instead, opt for rounded corners and simpler shapes that are easier to mill.

Conclusion

Partnering with a reliable CNC milling service provider is the key to accessing cutting-edge technology and expertise. These professionals are constantly updated with the latest advancements in the industry, ensuring that their clients benefit from the most innovative techniques and solutions.

To get started with a 3D CNC milling service, it is crucial to first identify your requirements and find a reputable service provider. Look for a company that has a proven track record of delivering high-quality results and specializes in handling the specific materials you require.