Gears play a key function in lots of machines and automobiles. From vehicles to industrial devices, gears help switch motion and power. To ensure smooth operation, gears have to be unique and properly made. This is where CNC Gear Cutting is available. It is a popular process used to fabricate top gears. However, deciding on a reliable equipment hobbing manufacturer can be demanding. Many factors determine whether an industry can meet your desires. We’ll help you find the exquisite tools hobbing manufacturers for your industrial employer.

What is Gear Hobbing?

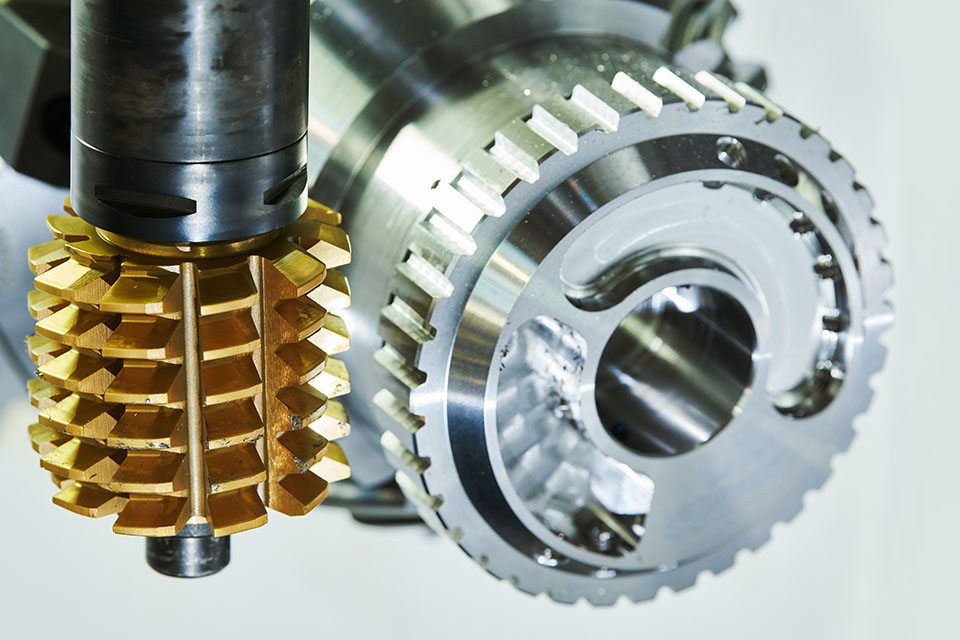

Gear hobbing is a machining procedure for creating gears of diverse sizes and styles. It uses a hob device that cuts the gear enamel right into a workpiece. The system is green and guarantees excessive accuracy. Precision Gear Manufacturing is significantly used as it allows for mass production and maintains precision.

What Industries Use Gear Hobbing Services?

Many industries rely upon device hobbing to provide top-notch tools. The automotive industry uses device hobbing to manufacture engines, transmissions, and differential gears. Aerospace businesses need unique gears for aircraft engines and navigation systems. Industrial machinery manufacturers depend upon hobbing to create gears that operate heavy-obligation devices. Even the medical field calls for small, particular gear for specialized devices. Hobbing Machine Technology is vital in many sectors that require long-lasting and dependable gear structures.

Can Gear Hobbing Manufacturers Create Custom Gears?

Gear hobbing manufacturers can create custom gears based on particular wishes. Custom gears are frequently required in industries wherein trendy gears do now not match the design. A dependable manufacturer can produce gears with unique shapes, sizes, and materials. The advanced CNC technology allows for the advent of exact complex gear designs.

How Do I Choose a Reliable Gear Hobbing Manufacturer?

Selecting an honest Metal Gear Fabrication manufacturer calls for careful studies. Here are key elements to don’t forget:

Experience and Expertise

A manufacturer with years of experience in equipment hobbing is likelier to produce great gear. Look for an agency with solid recognition and a track record of providing unique gear. Skilled engineers and technicians play a key role in retaining accuracy and consistency.

Advanced Technology and Equipment

Industrial Gear Production requires specialized equipment. A reliable manufacturer invests in modern CNC machines to ensure precision and efficiency. Advanced era reduces errors and increases manufacturing speed. Before choosing a manufacturer, test if they use terrific equipment for their equipment hobbing techniques.

Material Selection

The pleasantness of gears depends on the substances used. A proper manufacturer offers many materials, including metal, brass, aluminum, and titanium. Different applications require distinct substances, so working with a manufacturer who knows fabric houses and their effect on tools’ overall performance is critical.

Customization Capabilities

If your challenge requires custom automotive Gear Components, choose a manufacturer with design and customization offerings. They ought to be capable of creating gear that meets your specific specifications. An industry with strong customization competencies can handle complicated designs and the necessity of particular tools.

Quality Control and Certifications

Quality is among the most critical factors when selecting an equipment hobbing manufacturer. Look for corporations that follow strict, best control measures. Certifications, such as ISO 9001, suggest that an organization meets global best standards. A dependable manufacturer must regularly inspect each tool to meet particular specifications.

Production Capacity and Lead Time

The potential to address massive orders efficaciously is crucial. A manufacturer with an excessive manufacturing capacity can meet cut-off dates without compromising quality. Ask approximately their lead time and whether or not they can supply gears within your required timeframe. Fast and green manufacturing ensures that your business operations run smoothly.

Customer Reviews and Reputation

Check purchaser evaluations and testimonials to learn about a manufacturer’s reputation. Positive remarks from different organizations show reliability and excellence. Look for case research or fulfillment memories that show how the manufacturer has helped customers with their tool needs.

Competitive Pricing

While great is a priority, pricing additional topics. Compare prices from one-of-a-kind manufacturers to find stability between cost and quality. The cheapest alternative won’t continually be the first-class, so don’t forget the overall cost a manufacturer offers.

After-Sales Support and Warranty

The proper manufacturer provides extraordinary customer service. Ask about warranties and after-sales services. A reliable company will also offer steering, troubleshooting, and preservation offerings if desired.

Why Choose Junying: Best Custom Gear Hobbing Components Manufacturer

Junying is a trusted name in CNC manufacturing. With decades of experience, Junying offers China’s best custom Gear Machining services. The employer offers a one-stop solution for OEM clients, which includes CNC machining components and prototypes. Their know-how ensures high precision and sturdiness in each piece of equipment they produce.

Our Gear Hobbing Step-by-Step Process

Junying follows a detailed procedure to ensure that each tool meets high standards.

Material Selection

The method starts by choosing the proper fabric primarily based on customer wishes. Junying offers various materials, ensuring the excellent health of each software.

Gear Design and Customization

Customers offer specs, and Junying’s engineers create particular designs. Advanced software ensures accuracy earlier than production begins.

Hobbing Process:

Using state-of-the-art CNC hobbing machines, Junying cuts the equipment teeth excessively. The automatic process ensures consistency and performance.

Quality Inspection

Every tool undergoes strict, acceptable assessments. Measurements and tolerances are tested to ensure the final product meets the required standards.

Surface Treatment and Finishing

Junying offers remedies to enhance sturdiness, together with warmth treatment, coating, and polishing. This step guarantees longevity and overall performance.

Final Delivery

Once gears pass all quality tests, they’re packaged and shipped to customers. Junying guarantees timely transport and terrific customer support.

Key Takeaways

Choosing a dependable gear hobbing manufacturer is critical for getting excellent gear. Look for enjoyment, advanced generation, customization capabilities, and strict, satisfactory control. Junying is a leading CNC manufacturer with a long time of information. Their dedication to the best, superior machinery, and remarkable customer support cause them to desire custom tools hobbing additives. When you need unique and sturdy gears, Junying is the manufacturer you can accept as accurate.