Imagine a process that shapes metal with sparks! That’s Electrical Discharge Machining (EDM) for you. Instead of traditional cutting tools, EDM uses electrical sparks to mold and shape metal parts. It’s a fascinating method that has revolutionized the manufacturing world.

The Basic Components of EDM

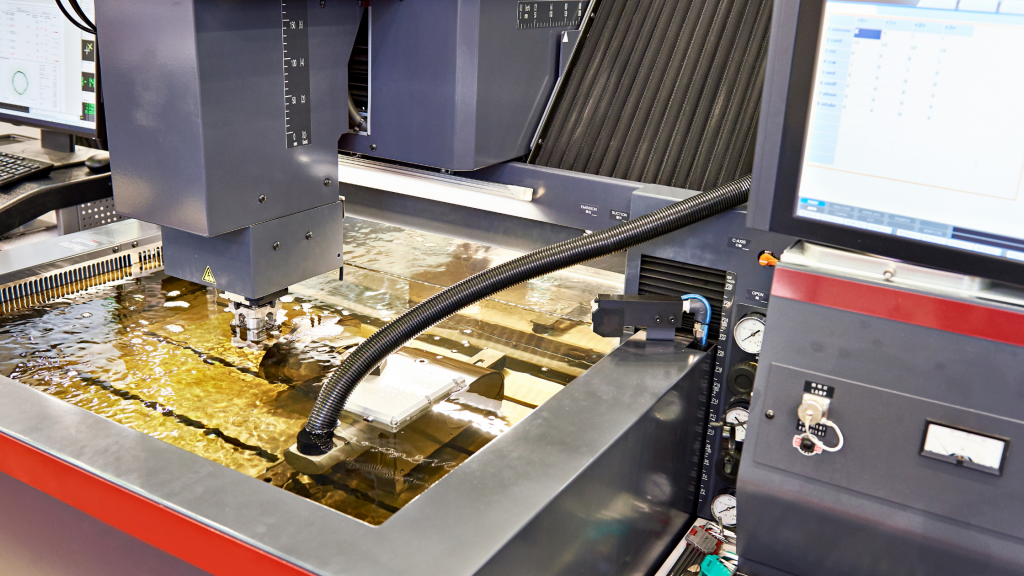

At its core, EDM relies on two main parts: an electrode and a workpiece. The electrode delivers the electrical charge. The workpiece is the metal you want to shape. Both of these components are submerged in a special fluid called dielectric fluid.

Why Dielectric Fluid?

This fluid is crucial to the Electrical Discharge Machining process. First, it acts as an insulator. That means it prevents electricity from flowing until the time is right. Once the electrode is close enough to the workpiece, sparks fly! The dielectric fluid also serves another role. After each spark, some metal melts or vaporizes. This fluid washes away these tiny particles. Moreover, it cools the area, preventing overheating.

The Sparking Magic

Here’s where the real magic happens. The electrode moves closer to the workpiece but never touches it. When they get close, a spark jumps between them. Each spark produces intense heat. This heat causes tiny bits of metal to melt and evaporate. Over time, as the electrode moves and produces more sparks, the desired shape emerges in the workpiece.

Types of EDM Processes

There are mainly two types of EDM processes:

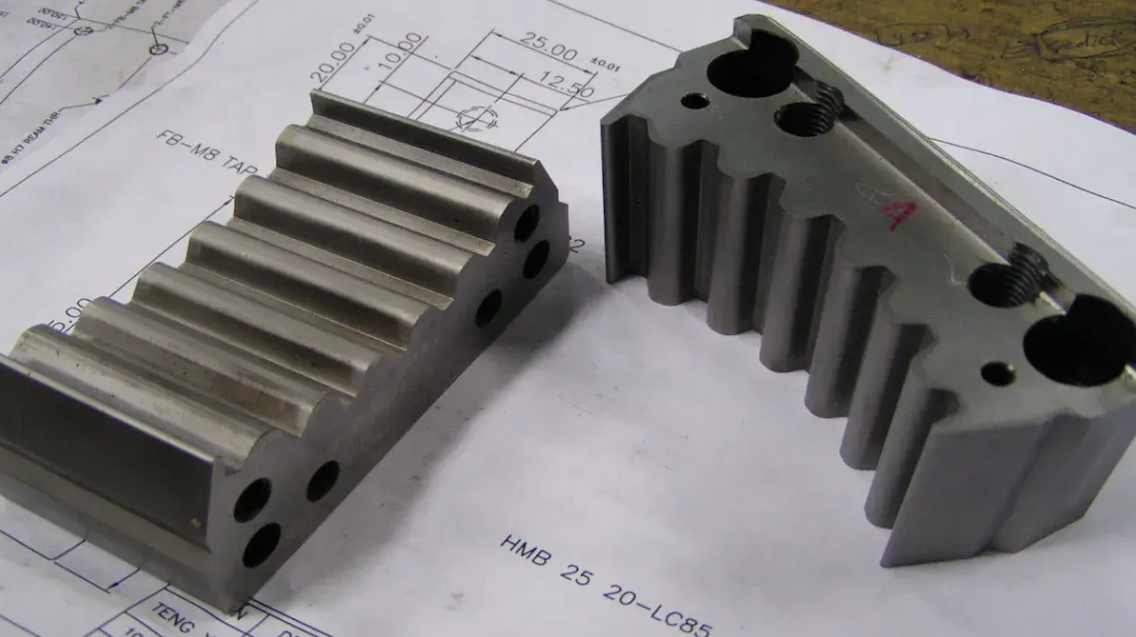

Sink EDM (or Ram EDM)

In this method, a shaped electrode moves towards the workpiece. The shape of the electrode determines the final shape of the workpiece. It’s like pressing a mold into clay, but with sparks!

Wire EDM

Imagine a thin wire moving through a metal block, like a cheese slicer. The wire acts as the electrode. As it moves, it sparks and cuts through the metal. This process is perfect for making intricate cuts and designs.

Why Choose EDM?

So, why might someone pick EDM over traditional machining? There are a few reasons:

Material Hardness Doesn’t Matter: EDM doesn’t care how hard the metal is. It can shape tough metals with ease.

Precision: EDM offers incredibly precise results. It’s perfect for making small, intricate parts.

No Physical Force: Traditional machining puts physical force on the metal. This can cause issues. EDM doesn’t apply any physical force. It’s all about the sparks.

Complex Shapes: With EDM, you can achieve shapes and designs that might be impossible with other methods.

Industries That Use EDM

Various industries have embraced EDM for its benefits. Here are a few:

Aerospace: Planes need precision parts. Electrical Discharge Machining provides that accuracy.

Automotive: Car parts, especially in high-performance vehicles, often use EDM-made components.

Mold-making: Molds need to be perfect. A slight error can ruin many products. EDM ensures mold accuracy.

Medical: Think of tiny, precise medical instruments. Many of these come from EDM processes.

Caring for the Environment

Modern Electrical Discharge Machines are environmentally conscious. They often have filters to clean the used dielectric fluid. Clean fluid ensures efficient sparking. The cleaned fluid can be reused, reducing waste.

A Few Limitations

While EDM is fantastic, it’s not perfect. It’s slower than some traditional methods. Also, it only works with conductive materials. So, non-metals or some metals with poor conductivity might not be suitable.

Final Thoughts

Electrical Discharge Machining is a modern marvel in the world of manufacturing. Using the power of electrical sparks, it shapes metals into precise, intricate designs. Whether you’re looking at a high-speed plane, a sports car, or a medical tool, there’s a good chance EDM played a part in its creation. It stands as a testament to human ingenuity, taking something as simple as a spark and turning it into a powerful tool for creation.

FAQs

What is Electrical Discharge Machining (EDM)?

EDM is a machining method. It uses electrical sparks to shape metal parts. Instead of cutting, it melts or vaporizes the metal.

How does EDM differ from traditional machining?

Traditional machining uses physical tools to cut metal. EDM uses electrical sparks. No direct contact happens between the tool and metal in EDM.

Can EDM work on any material?

No, EDM works on conductive materials, mainly metals. Non-conductive materials can’t be machined using this method.

Why is dielectric fluid used in EDM?

The dielectric fluid serves multiple roles. It acts as an insulator, cools the process, and washes away melted particles.

Are there different types of EDM processes?

Yes! The two main types are Sink EDM and Wire EDM. Sink EDM uses shaped electrodes, while Wire EDM uses a thin wire to cut through metal.