Ever looked at a metal surface and wondered how it got so shiny and smooth? The secret often lies in a process called electropolishing. Think of it as a spa treatment for metals. Instead of adding layers like in plating, electropolishing gently strips away imperfections. This method uses electricity and a special bath to give metals a gleaming finish. It’s not just about beauty; it also enhances the metal’s durability. If you’re curious about how this magical transformation happens, let’s dive deeper into the world of electropolishing!

What is electropolishing?

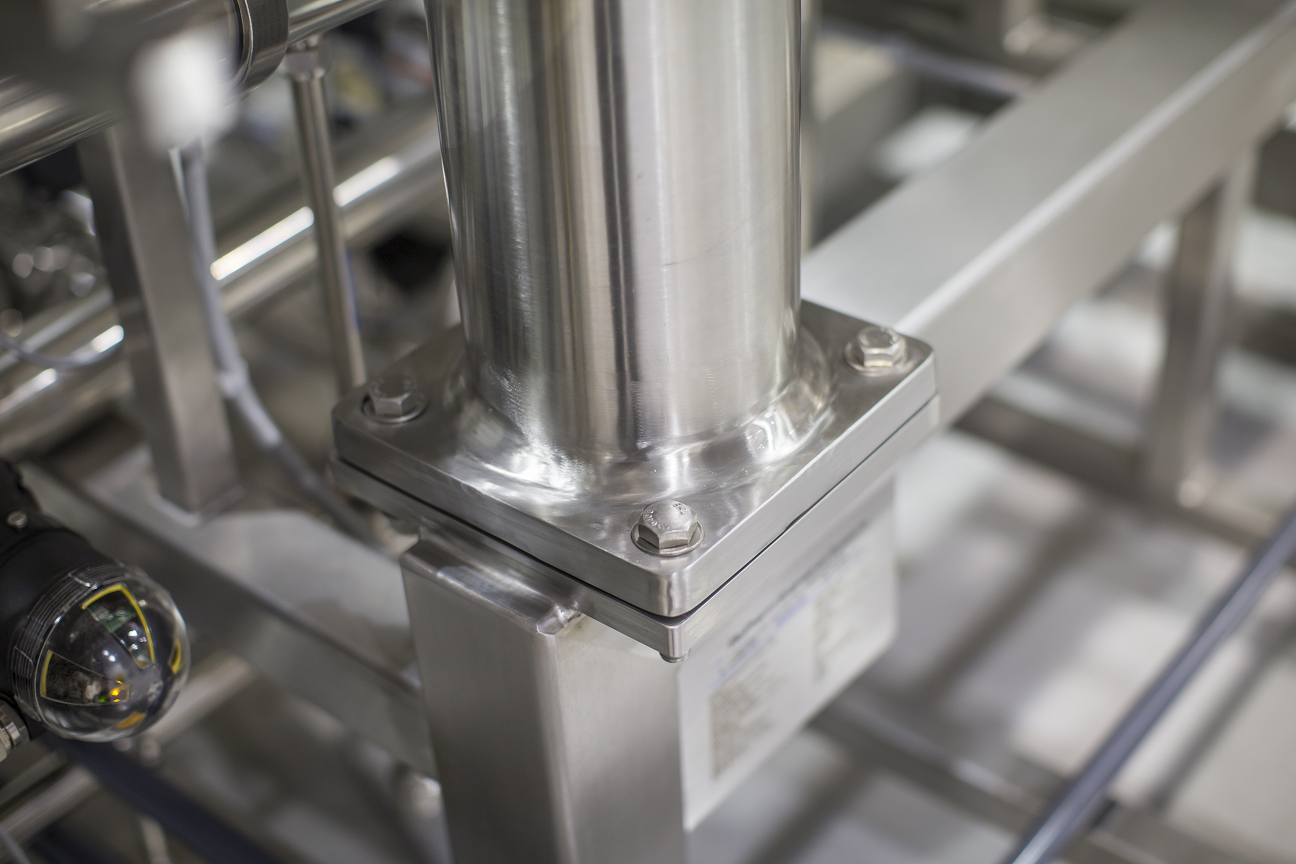

Electropolishing is like a reverse electroplating. Instead of adding material, it removes it. Here’s how it works: A metal piece becomes the anode in an electrolytic cell. When we apply an electric current, the piece’s surface dissolves. This process smoothens and polishes the metal. Impurities, roughness, and burrs go away. The result? A bright, smooth, and shiny surface. This technique benefits many industries. For example, medical devices and food processing equipment. They need clean, smooth surfaces. Electropolishing helps achieve that. In simple terms, it’s an electrical way to make metal look and feel better.

How does electropolishing work?

Imagine you have a metal object. It might look smooth, but if you zoom in, its surface is full of tiny hills and valleys. These imperfections can cause issues. They trap dirt, grow bacteria, or cause wear. So, how do we make it super smooth? Enter electropolishing.

Step 1: The Setup

First, you need a bath with a special liquid called an electrolyte. This liquid conducts electricity. You also need two electrodes: one made of your metal (this is your workpiece) and another called the cathode. The metal piece you want to polish becomes the anode. The other electrode, usually made of lead or stainless steel, becomes the cathode.

Step 2: The Electric Connection

Now, connect your workpiece (the anode) and the cathode to a power source. Switch it on. Current flows from the anode to the cathode, through the electrolyte. This current is crucial. It does all the magic.

Step 3: The Reaction

Here’s where the fun happens. The electric current makes the metal ions leave the anode. They move into the electrolyte. This process removes the outermost layer of the metal. Picture it like sanding wood, but on a micro-level. The high points or “hills” on the metal dissolve faster than the valleys. So, the surface becomes level and smooth.

Step 4: The Results

After some time, turn off the current. Take out your workpiece. You’ll notice it’s shinier and smoother. The metal’s micro-structure improves too. This means you’ve not just made it pretty, but also stronger in some cases. Rust resistance can increase as well. The surface is now free from tiny cracks where corrosion starts.

Benefits of Electropolishing

Cleanliness: The smooth surface makes it hard for contaminants to stick. This is super important for industries like food processing. We don’t want bacteria hiding in our equipment.

Shiny Finish: For items that need to look great, electropolishing is a top choice. Think about cutlery or jewelry.

Less Friction: A smoother surface means less friction. This is useful for parts that move and slide.

Electropolishing vs. Mechanical Polishing

Now, you might wonder, “Why not just polish the metal mechanically?” Good question! Mechanical methods, like grinding or buffing, do polish metal. But they might introduce new imperfections. They could push contaminants into the surface. Electropolishing doesn’t do this. Instead, it removes material evenly and cleans as it polishes. It’s like giving metal a spa treatment.

Some Quick Tips

If you’re considering electropolishing, keep these points in mind:

Material Matters: Not all metals respond the same way. Stainless steel, for example, electropolishes really well. Some metals might need specific electrolytes.

Safety First: Working with electricity and chemicals demands caution. Always wear safety gear. Make sure to follow guidelines.

Closing Thoughts

Electropolishing is an amazing technique. It offers a blend of beauty and functionality. It’s like a magic trick for metals: transforming rough surfaces into gleaming, smooth finishes. Whether you’re in an industry that needs super-clean equipment or you just love the shine, electropolishing delivers. Remember, it’s not just about looking good. It’s about enhancing the metal’s properties to serve us better.

FAQs

What metals can I electropolish?

Most metals can undergo electropolishing. Common choices include stainless steel, aluminum, and copper. But always check the metal’s compatibility with the process.

How long does the electropolishing process take?

It varies based on the metal and desired finish. Typically, it takes minutes to a few hours. The thicker the imperfections, the longer it might take.

Is electropolishing safe for my metal item?

Yes, if done correctly. Electropolishing won’t weaken or damage your metal. In fact, it often improves the metal’s corrosion resistance.

How does electropolishing compare to traditional polishing?

Traditional methods, like buffing, physically remove material. They might introduce new imperfections. Electropolishing dissolves imperfections evenly and enhances the metal’s properties.

Does the metal lose a lot of material during electropolishing?

Only a small amount of material gets removed. It’s typically the outermost layer of the metal. The goal is a smoother and cleaner surface, not thinning the item.