In the domain of assembling, Computer Numerical Control (CNC) machines have reformed the business. These machines, which utilize electronic controls to work and control machine devices, have turned into a staple in different areas, from cars to aviation. The CNC machine is a useful asset that offers accuracy, effectiveness, and flexibility.

Buying a CNC machine, in any case, isn’t a choice to be messed with. It requires a careful comprehension of the machine’s capacities, the particular necessities of your business, and the monetary ramifications of such a buy. This guide plans to give a detailed answer on how to buy a cnc machine.

Kinds of CNC Machines

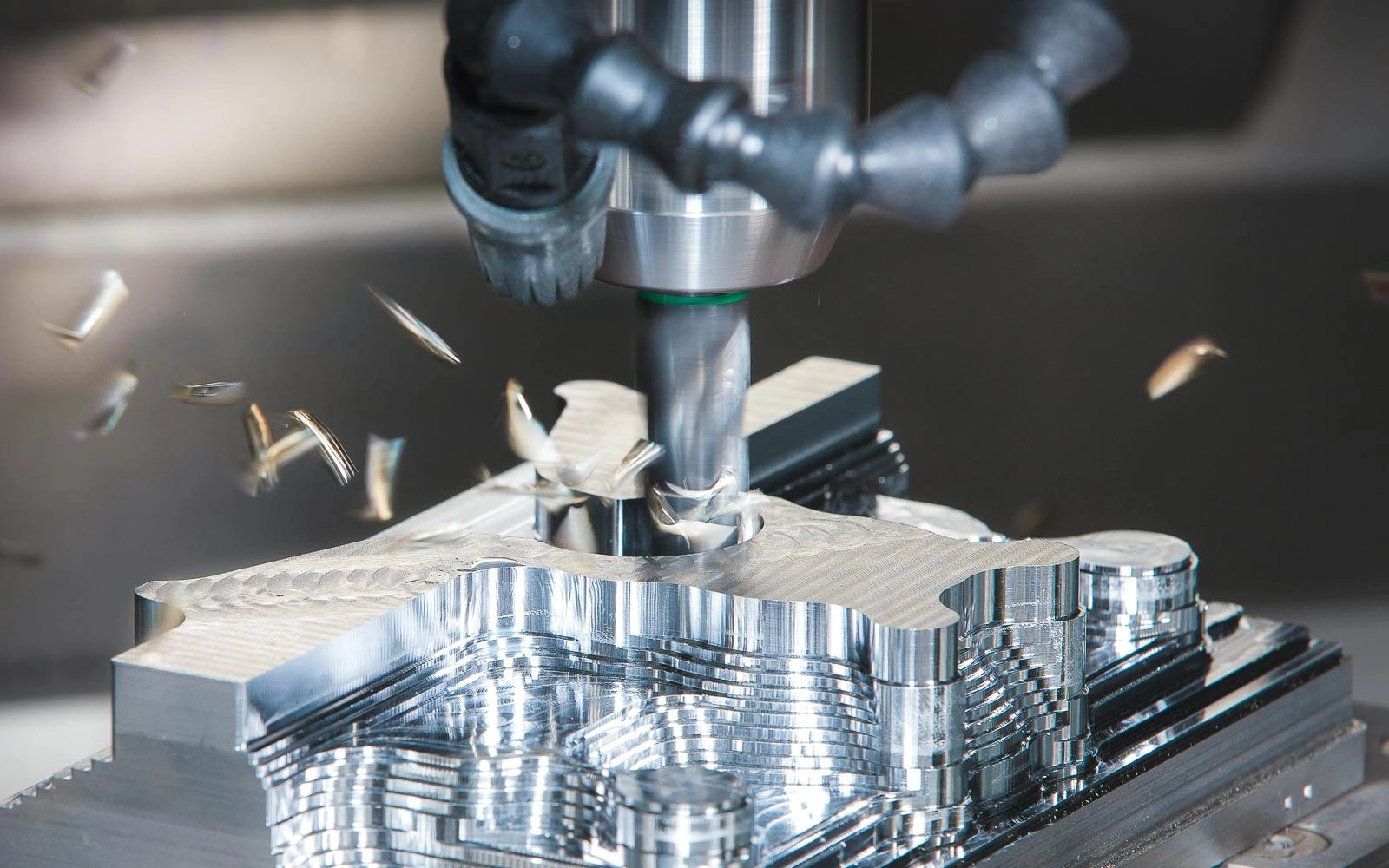

A. Milling Machines

CNC Milling Machines, the workhorses of the assembling business, utilize revolving cutters to eliminate material from a workpiece. They work in fluctuating tomahawks, from fundamental three-hub machines for straightforward undertakings to complex five-hub machines for mind-boggling, multi-sided parts. The flexibility of CNC Milling Machines makes them a crucial device in numerous enterprises, including cars and aviation.

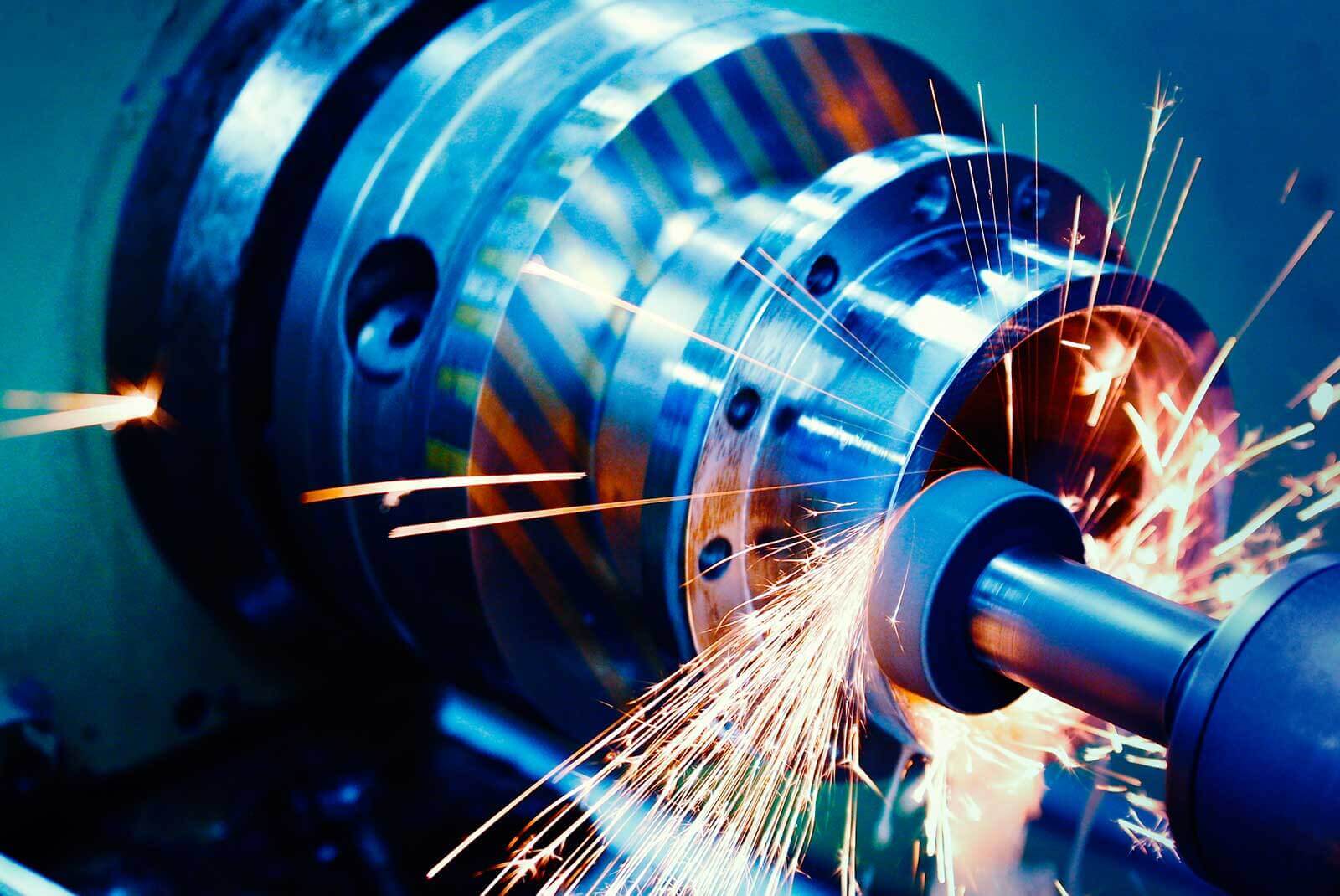

B. Lathes

CNC machines, or turning machines, pivot a workpiece on a shaft to perform different tasks like cutting, sanding, or boring. These machines are ideally suited for making even articles like cones and chambers. Enterprises, for example, cars and hardware use CNC machines for their accuracy and consistency.

C. Plasma Cutters

CNC plasma cutters are a wonder in the metalworking field. They utilize a high-speed stream of ionized gas, or plasma, to slice through conductive materials like steel, aluminum, or metal. The outcome is a spotless, exact cut with a smooth completion. This causes CNC plasma cutters ideal for businesses that require point-by-point metalwork, like development and cars.

D. 3D Printers

CNC 3D printers have upset the universe of assembling. Dissimilar to customary CNC machines that eliminate material, 3D printers add material layer by layer to make an item. This added substance producing considers complex calculations and handcrafts. It makes 3D printers a number one in ventures from medical services to mold.

How To Buy A Cnc Machine: Consider While Purchasing a CNC Machine

Here are the main key factors to consider while purchasing a CNC machine.

1. Grasp Your Necessities

Before you begin shopping, understanding your needs is significant. What materials will you be working with? What sort of activities will you be performing? The responses to these inquiries will direct you towards the right sort of CNC machine. For example, if you’re working with metal, a CNC Milling Machine may be the ideal choice. Then again, on the off chance that you’re managing wood, a CNC switch would be more reasonable.

2. Machine Size and Workspace

CNC machines come in different sizes, from little work area models to enormous modern ones. Consider the space you have accessible in your studio. Keep in mind, that you’ll likewise require space for other hardware, stockpiling, and development around the machine.

3. Software Compatibility

Guarantee the CNC machine you pick is viable with the product you intend to utilize. A few machines accompany their product, while others require outsider programming. It’s fundamental to pick a machine that works consistently with your favored plan and control programming.

4. Training and Support

Working on a CNC machine requires expertise and information. If you or your group are new to CNC machining, consider the preparation and backing given by the producer. Some propositions are thorough preparation programs and progressing specialized help, which can be important for amateurs.

5. Budget

CNC machines can fluctuate fundamentally in cost, contingent upon their size, abilities, and brand. It’s vital to set a spending plan before you begin shopping. Notwithstanding, don’t think twice about quality to set aside cash. A modest machine might wind up costing more over the long haul because of successive breakdowns and support.

6. After-Sales Service

After-deals administration is one more basic component to consider. A decent producer will offer brief and effective support, assisting you with settling any issues that might emerge. Check the guarantee time frame and what it covers. Additionally, think about the accessibility of extra parts.

7. Reviews and Recommendations

Finally, remember to take a look at surveys and get suggestions. Converse with others in your industry who have bought CNC machines. Their encounters can give you important experiences and assist you with keeping away from possible entanglements.

Purchasing a CNC machine is a huge choice that requires cautious thought. By remembering these variables, you can settle on an educated decision that will work well for your business into the indefinite future.

Last Words

CNC machines can fundamentally improve your business’ efficiency and seriousness. The accuracy and productivity presented by these machines are unrivalled, making them a beneficial expansion to your tasks. Notwithstanding, taking into account your particular necessities and leading exhaustive exploration before making a purchase is critical. Keep in mind, that a CNC machine isn’t simply a buy; it’s an interest coming down the line for your business. By understanding the capacities of CNC machines and perceiving their significance, you can pursue an educated choice that will help your business over the long haul.