Connecting a Computer Numerical Control (CNC) Technology to a pc may seem tricky. But after you recognize the steps, it will become easier to do. Many factories and workshops use CNC machines to create accurate designs and merchandise. These machines paintings with computer systems to make unique moves. However, you must follow the steps to run the CNC device from a PC. Let’s destroy it in easy terms so that you can comply with it.

Why Connect a CNC Machine to a Laptop?

Using a pc to control a CNC device offers flexibility. You can upload new designs, make changes, and paint on the cross without problems. A computer offers you greater mobility than a computing device computer. It’s additionally easier to replace and improve your software on a pc. Plus, the general public is relaxed using laptops for tasks like those.

But how do you connect your CNC system to a computer? Don’t worry—we’ll guide you through it step by step.

Step-by way of-Step Guide to Connect a CNC Machine to a Laptop

Check the Compatibility of Your CNC Machine

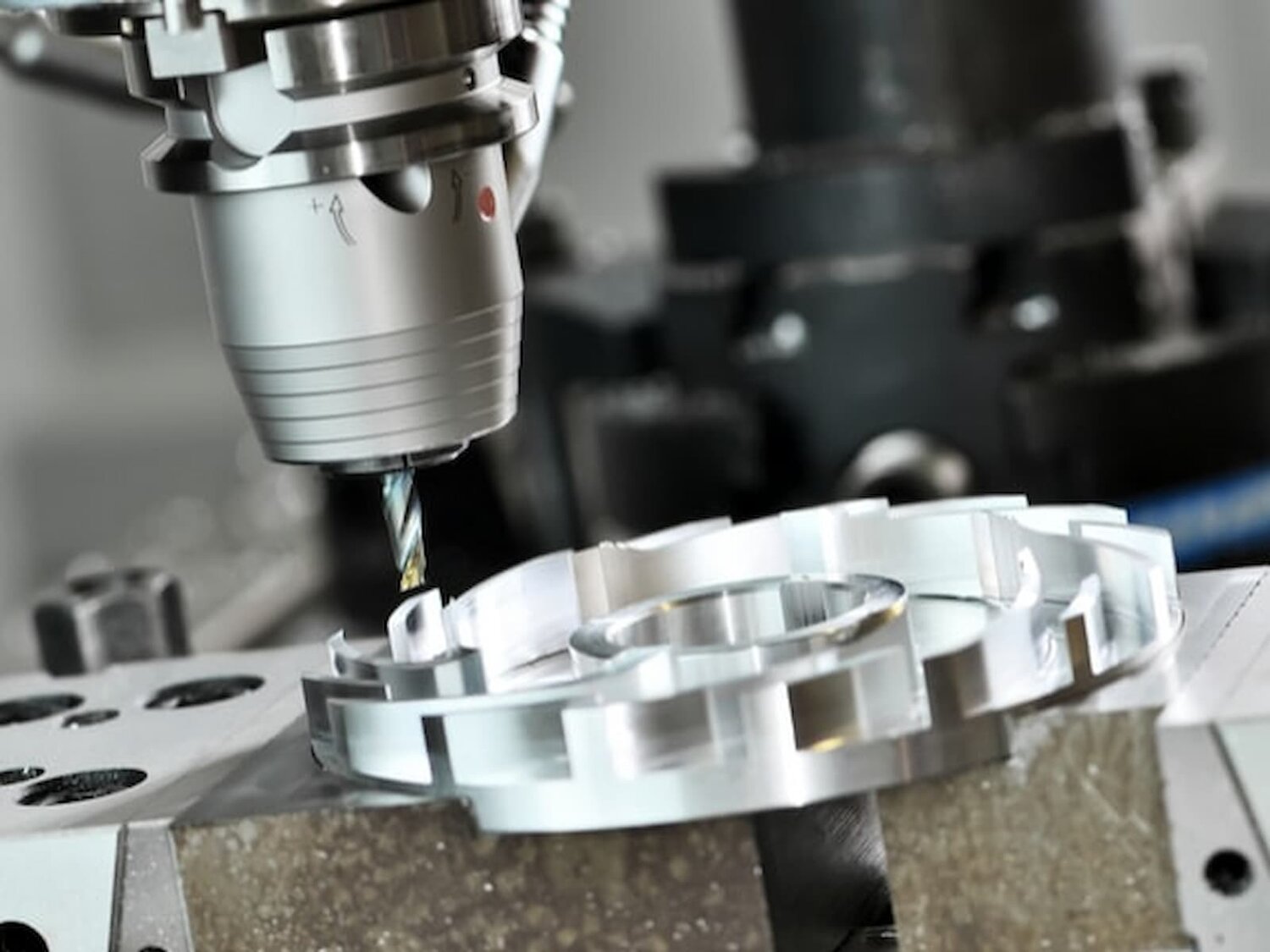

Before connecting, make sure your CNC Milling Machine is like-minded with laptops. Most modern CNC machines are, but some older models may need extra hardware. Check your device’s guide for details about compatibility.

Choose the Right Software

CNC Machining Services require particular software programs to perform. This software program allows the machine to understand instructions from your computer. Some popular software programs consist of:

- Mach3

- GRBL

- LinuxCNC

Pick the one that works best with your device and computer. The software program usually guides you through the installation process.

Use a USB or Parallel Cable

Most CNC machines connect with laptops using either a USB or parallel cable. A USB cable is more common and more straightforward to use. If your gadget uses a parallel port, you may need a unique adapter to attach to your computer’s USB port.

Plug one of the cables into your CNC device, and the opposite gives up into your laptop. Make sure the relationship is at ease.

Install Drivers

Your laptop may also need drivers to communicate with Precision Engineering. Drivers are small packages that assist your computer in recognizing linked gadgets. The CNC device’s manual must include commands on where to download the best drivers.

After downloading and installing the drivers, follow the on-screen prompts. This step is vital because, with the ideal drivers, your computer can manipulate the machine.

Configure the Software

Once the drivers are hooked up, open the CNC software on your computer. You will need to configure the software program to fit the settings of your CNC device. This includes things like:

- Spindle pace

- Movement velocity

- Cutting gear

The software needs to have a setup wizard that helps you enter those details. If you are unsure, consult your device’s manual or online sources.

Test the Connection

Before starting an assignment, it’s essential to test the relationship. Use the software program to send a basic command to the CNC machine. For example, you can tell the gadget to transport a small distance. If the device follows the command, the connection is operating efficiently. If not, take a look at the cables and settings again.

Load Your Design

Now that your CNC gadget is connected to your laptop, it’s time to load your design. Most CNC software programs help design documents like DXF, STL, or G-code. Simply add the design to the software program, regulate the settings, and send it to the system.

Once the design is uploaded, the CNC Lathe Machine follows the instructions and starts slicing or shaping the material.

Common Issues When Connecting a CNC Machine to a Laptop

While connecting a 3D CNC Programming to a laptop is straightforward, you might need help. Here are some common issues and how to fix them:

- If you don’t receive a response from the Machine, Check if the USB or parallel cable is securely connected. Sometimes, loose cables cause communication problems.

- Software Not Recognizing the Machine: Ensure the correct drivers are set up. Also, check if the CNC machine is powered on.

- Design File Won’t Load: Make sure your layout report is in a layout supported by the CNC software program. If the report is too big, try lowering its size.

Where to find the best CNC machining gadgets?

Top websites can assist you in your search for the best CNC machining devices. One of the top-notch vendors is Junying CNC Machining Center, known for its incredible gadgets and components. They offer high-precision production and diverse, accurate, and dependable CNC machining gear. They also provide one-of-a-kind custom CNC factors. The website offers centered product descriptions, critiques, and smooth ordering options.

FAQs

Can I connect any CNC device to a pc?

Most contemporary Metal Cutting Machines can connect to laptops, but older models may require adapters or special software. Always test the gadget’s manual for compatibility.

What software program must I use to govern my CNC system?

Numerous software alternatives exist, such as Mach3, GRBL, and LinuxCNC. The proper choice depends on your device and PC. For guidelines, refer to your machine’s manual.

What should I do if my CNC gadget isn’t responding to instructions?

First, check the relationship cables and ensure the gadget is powered on. If that doesn’t assist, reinstall the drivers or replace the software.

Final Words

Connecting a CNC system to a PC is easy if you observe the proper steps. You must ensure compatibility, deploy the perfect software, and secure the reference to the proper cables. By following these commands, you can quickly manage your CNC machine from your laptop. Remember to check the relationship before beginning any essential task and usually keep your software program updated. Once the whole lot is set up, you may experience the flexibility and simplicity of using your computer to control your CNC device!