Manufacturing industries rely on quality control to ensure their products meet the highest standards. One of the most critical steps in the best guarantee is the First Article Inspection (FAI). This allows for the picking out of any defects or inconsistencies earlier than full manufacturing starts. Choosing a reputable First Article Inspection offerings provider is vital to ensure the accuracy and reliability of your production procedure. But how do you find the proper one? We will explain the FAI process, provide a way to ensure the best control and suggest a way to pick the best FAI carrier company, especially in China.

What is the First Article Inspection Service?

First-article inspection (FAI) is an in-depth system in which the first few units of a production batch are inspected to verify that they meet the desired specs. This is a critical step in the production, aerospace, automobile, medical, and electronic industries. The supplier verification process includes measuring and analysing elements to ensure they meet layout requirements before complete-scale production starts.

The FAI aims to discover defects early, reduce waste, enhance efficiency, and ensure product reliability. It covers material properties, dimensions, floor end, and assembly verification. Producers can prevent costly errors, ensure compliance, and maintain steady, pleasant standards by undertaking an FAI.

How to Ensure FAI Quality Control in Your Manufacturing Process

Manufacturers should follow strict suggestions and pleasant practices for a practical First AS9102 inspection. Here are some key steps to make sure the right FAI quality is manipulated:

Establish Clear Inspection Standards

Before production, producers should outline unique, exceptional requirements based on enterprise necessities and customer specifications. These requirements require manual inspectors to evaluate the primary article.

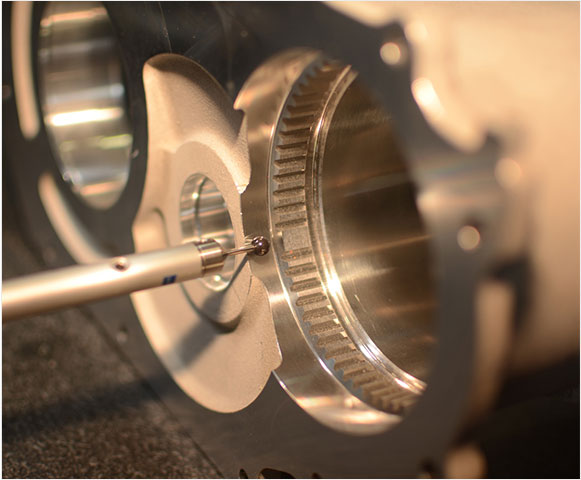

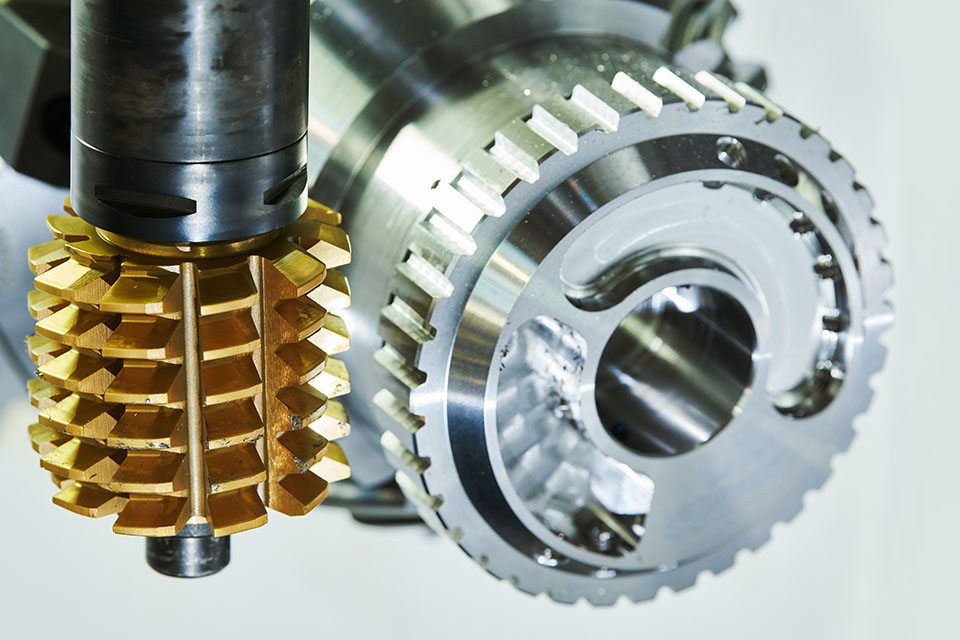

Use Advanced Inspection Equipment

Quality management relies upon excessive precision size tools, which include coordinate measuring machines (CMM), laser scanners, and optical comparators. These quality control audits ensure accurate measurements of parts.

Follow International Standards

First-article inspections should follow identified standards, such as AS9102 (for aerospace), ISO 9001, and IATF 16949 (for automotive). These requirements ensure consistency and reliability in production.

Document the Inspection Process

A unique FAI report should be created, including measurements, fabric houses, and compliance repute. This record is evidence of nice assurance and may be shared with customers.

Conduct Regular Quality Audits

Even after a manufacturing compliance check is approved, ongoing audits help maintain product quality throughout the production cycle. This ensures that any deviations are detected and corrected quickly.

How Do You Find a Reputable First Article Inspection Services Provider?

Finding a good FAI company requires careful research and assessment.

Start by seeking out providers with established industry experience. A company specialising in aerospace, automobile, or CNC machining inspections will have the information to fulfil your desires. Check their credentials and certifications, such as AS9102 for aerospace or ISO 9001 for trendy production, to ensure they meet global first-rate standards.

Next, study their inspection generation. To ensure precise and accurate measurements, a proper provider must have superior tools like Coordinate Measuring Machines (CMM), laser scanners, and optical comparators. Additionally, look into their inspection group’s qualifications. Experienced engineers and best manipulation experts are essential in delivering dependable results.

Customer evaluations and testimonials are also crucial. Look for feedback from beyond clients to decide if the issuer has a record of accuracy, reliability, and top-notch customer support. Case research and references can also develop a concept of their beyond initiatives and talents.

Turnaround time is another critical issue. A reliable company must offer efficient and timely services to save you from production delays. Ask about their lead times and whether they provide expedited inspection options.

Lastly, consider their reporting procedure. A dependable FAI provider should offer exact, easy-to-understand reports that include measurements, deviations, and pointers. Transparent verbal exchange is key to ensuring easy collaboration between manufacturers and inspectors.

Most Reputable First Article Inspection Services Provider in China

China has several top FAI companies, but Junying is the top in CNC production and inspection offerings. Its long history has provided one-forestall solutions for CNC machining components and prototypes. The enterprise operates hundreds of superior CNC machines, lathes, blasters, and ultrasonic washing machines. Junying’s professional team of engineers, operators, and inspectors ensures that every client’s layout involves existence with precision. By using present-day measuring gadgets and following strict exceptional management standards, Junying offers dependable FAI offerings that meet worldwide enterprise requirements.

Our First Article Inspection Service Procedures

We observe a systematic process to ensure correct and reliable FAI effects. First, we review the client’s technical drawings and specifications. This facilitates us in understanding all dimension necessities. Next, we pick the proper dimensional inspection report, including CMM, laser scanning, and excessive-precision callipers. Our professional inspectors then degree and report each essential size. After that, we evaluate the consequences with the authentic design and identify any deviations. We notify the patron and propose corrective moves if any issue is found. Finally, we generate a detailed FAI report as a first-rate reference for future manufacturing. This dependent method ensures excessive accuracy, minimises defects, and keeps product consistency.

Key Takeaways

For organisations producing in China, Junying CNC Machining is a top priority. Their know-how, advanced gadgets, and commitment to excellence make them a trusted companion for production part approval and CNC manufacturing.

If you need a dependable FAI carrier provider, contact Junying CNC Machining today to ensure your product meets the highest requirements.