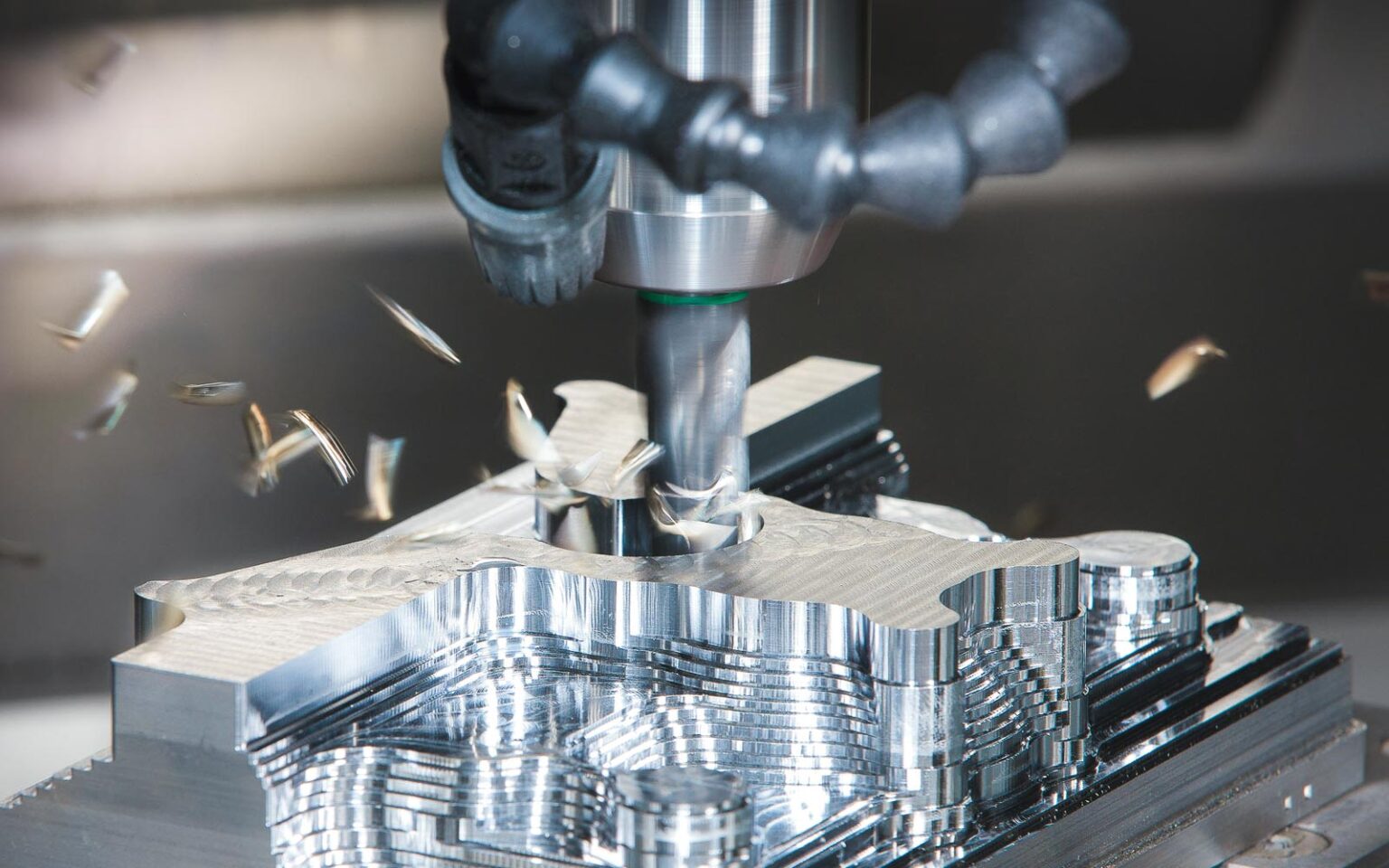

CNC (Computer Numerical Control) machining has become a cornerstone of present-day production. With technological advancements and a wide range of brilliant substances, CNC machining is more versatile and reachable than ever. It caters to everything from hobby projects and prototyping to huge-scale manufacturing. CNC machining remains a famous industry desire thanks to its precision, reduced manual labor, and regular excellence.

Selection of CNC machining materials is one of the most critical steps in any CNC undertaking. The right fabric guarantees the final product’s durability, performance, and value-effectiveness. The CNC material selection guide will assist you in recognizing the most common CNC substances and their applications and picking out the proper ones.

Why Material Selection Matters?

Remember several common CNC machining metals when deciding on substances for a CNC venture. Environmental situations play a sizeable function, as some properties of CNC materials are better applicable to intense temperatures, moisture, or corrosive environments. Thermal and electrical conductivity is also vital if the cloth desires to expend warmth or conduct energy. The material’s mechanical strength determines how much load it can bear, which is essential for structural or heavy-duty packages. Surface end and aesthetics are equally critical, especially for consumer merchandise or decorative objects.

Most Important CNC Materials Series Used in CNC Projects

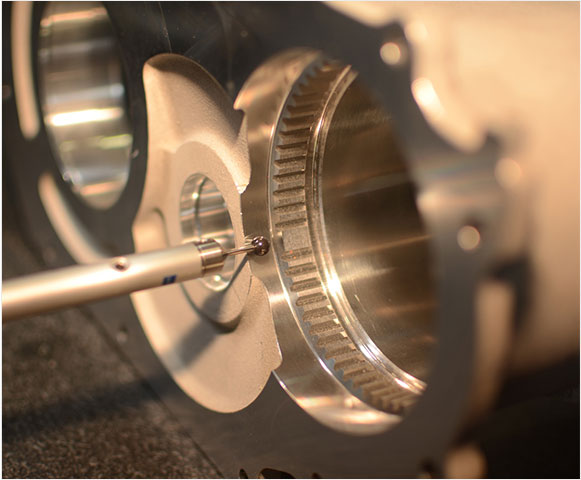

Stainless Steel

Stainless steel is one of the most used CNC plastic materials for machining. Known for its power and corrosion resistance, it’s miles a first-rate preference for additives that face harsh environments. Its natural protective oxide layer enhances its durability. Popular stainless-steel grades like 304, 316, and 17-4 PH provide several houses suitable for precise packages. For example, 316 stainless steel consists of molybdenum to grow its corrosion resistance, and even 303 stainless steel includes sulfur for stepped-ahead machinability.

Stainless steel is broadly used in the scientific, aerospace, automobile, and business sectors. It is a common choice for surgical devices, kitchen domestic devices, bolts, and gears. CNC machining of stainless steel is a properly established method, and most device stores are ready to supply super effects with this cloth.

Aluminum

Aluminum is a flexible and mild-weight cloth used extensively in CNC machining. Its superior machinability, corrosion resistance, and thermal and electric conductivity make it a favorite throughout industries. Compared to stainless steel, aluminum is more lightweight, making it perfect for programs wherein weight reduction is crucial.

Due to its terrific heat conduction properties, aluminum is used in aerospace components, automobile additives, consumer electronics, and cookware. While aluminum is pretty machinable, it can require positioned up-processing to attain the popular quit or ground trends. Its lower cost and flexibility make it a brilliant choice for many duties.

Titanium

Titanium has converted many industries with its top-notch homes. This material is fantastically robust, mild-weight, and corrosion-resistant, making it suitable for traumatic applications. Titanium’s biocompatibility has made it a favorite for implants and surgical gadgets within the scientific company. In aerospace and navy programs, titanium is prized for its strength, creep resistance, and durability in immoderate conditions.

Titanium alloys, including Ti-6Al-4V, provide a unique combination of strength and lightness. While titanium is more expensive than other materials, its advanced traditional average performance in aggressive environments justifies the price for high-stakes programs. From lightweight client merchandise like golfing systems to critical aerospace additives, titanium stays preferred for superior production.

Copper

Copper is known for its incredible electrical and thermal conductivity. While natural copper may be challenging to work with because of its malleability, various copper alloys offer improved machinability while maintaining similar conductivity properties.

Copper alloy one zero one is relatively ductile and gives advanced conductivity, making it suitable for digital components and wiring. On the other hand, copper alloy one hundred ten combines splendid conductivity with higher corrosion resistance. This makes it best for packages like electric additives, gaskets, and marine hardware. Copper is widely utilized in industries wherein thermal or electric performance is essential, which include electronics and renewable energy structures.

Brass

Brass, an alloy of copper and zinc, is used in many residences with copper but is less complicated to device. It is long-lasting, corrosion-resistant, and electrically conductive, making it appropriate for many programs. Brass additionally has a low friction coefficient, enhancing its wear resistance.

One of the most machinable brass alloys is 360 Brass, often called unfastened-machining brass. It is heavily used in plumbing, electric components, or musical contraptions. Its notable machinability and corrosion resistance make it flexible for industrial and decorative functions.

Alloy Steel and Carbon Steel

Steel is some other cornerstone cloth in CNC machining, with alloy and carbon steel being broadly used kinds. Carbon metal, as its call suggests, contains carbon as the primary alloying detail. Low-carbon metal, such as 1018, is low-priced and, without complicated, machinable, making it suitable for components like motor shafts, pump shafts, and furniture. Medium-carbon metal, which includes AISI 1045, offers better electricity and is often used for heavy-responsibility applications like bolts and studs.

Alloy metal beautifies its homes by adding alloying elements like chromium, molybdenum, or manganese. For instance, 4130 alloy metal is heat-resistant and wear-resistant, while 4140 offers excellent power at excessive temperatures. Alloy metal is utilized in everything from business equipment to cooking utensils and automobiles.

Plastics

Plastics are a unique magnificence of CNC substances, offering lightweight, value-powerful options to metals. Many plastics, including HDPE, are chemically and moisture-resistant, making them ideal for chemical containment and laboratory equipment programs. Nylon, regarded for its put-on resistance, is used in bearings and shifting components.

PEEK is another standout plastic material. It is lightweight, resistant to chemicals and wear, and might even replace gentle metals in positive programs. Polycarbonate, a commonly machined plastic, offers terrific heat and effect resistance. Due to their versatility and affordability, plastics are extensively used in the medical, automotive, and electronics industries.

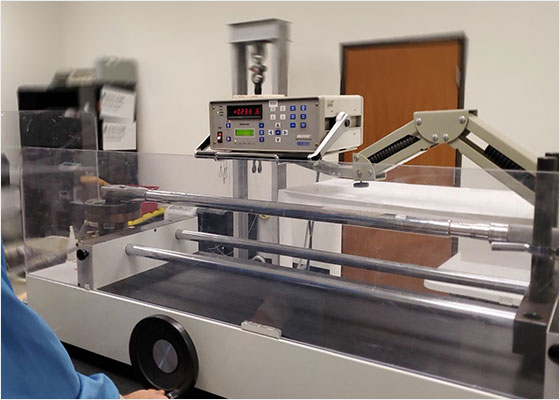

Where Do I Find Cnc Machine Parts?

It’s essential to find a reliable issuer if you’re looking for the best metals for CNC machining or a dependable issuer that offers notable CNC gadget elements. You can find numerous CNC gadget factors from multiple sources online, but the best place to get them is the Junying CNC Machining Center. They are known for offering precision CNC elements that meet organizational necessities.

Junying CNC Machining Center provides CNC spare parts, from frames and reducing devices to spindles and controllers. They provide long-lasting and specific factors for all sorts of CNC machines. Whether you need custom CNC components for a restoration or an improvement, Junying has you covered. Their products are designed to enhance performance and improve your machine’s lifestyle.

FAQs

What elements need to be remembered when selecting applications of cnc materials?

You should remember environmental conditions, mechanical electricity, floor end, price range, and weight requirements. Matching the fabric to your challenge’s needs ensures good overall performance and cost-effectiveness.

Why is aluminum so popular in CNC machining?

Aluminum is lightweight, corrosion-resistant, and tremendously machinable. It’s a low-cost alternative for industries like aerospace, automobiles, and consumer electronics, where weight and precision are essential.

Can plastics be used in CNC machining?

Yes, plastics like HDPE, nylon, PEEK, and polycarbonate are first-rate options. They are lightweight, value-powerful, and flexible, making them appropriate for clinical, car, and electronics programs.

CNC machining provides unrivaled precision and quality, and selecting the right fabric is vital for fulfilling your venture. Whether you need electricity from stainless steel, aluminum’s lightweight nature, or copper’s conductivity, knowing the properties of different substances lets you make the best choice. With many alternatives available, CNC machining keeps revolutionizing industries and conveying revolutionary designs to life.