If you’re in need of precise and complex parts for your business, custom CNC milling services may be the answer. CNC milling is a manufacturing process that uses computer-controlled machines to remove material from a workpiece, resulting in a highly accurate and detailed finished product.

In this blog post, we’ll explore the benefits of using custom CNC milling services for your manufacturing needs. From increased efficiency and cost savings to improved quality and design flexibility, there are numerous advantages to utilizing this advanced technology. So, if you’re interested in learning more about how custom CNC milling services can benefit your business, keep reading!

What is CNC milling and how does it work?

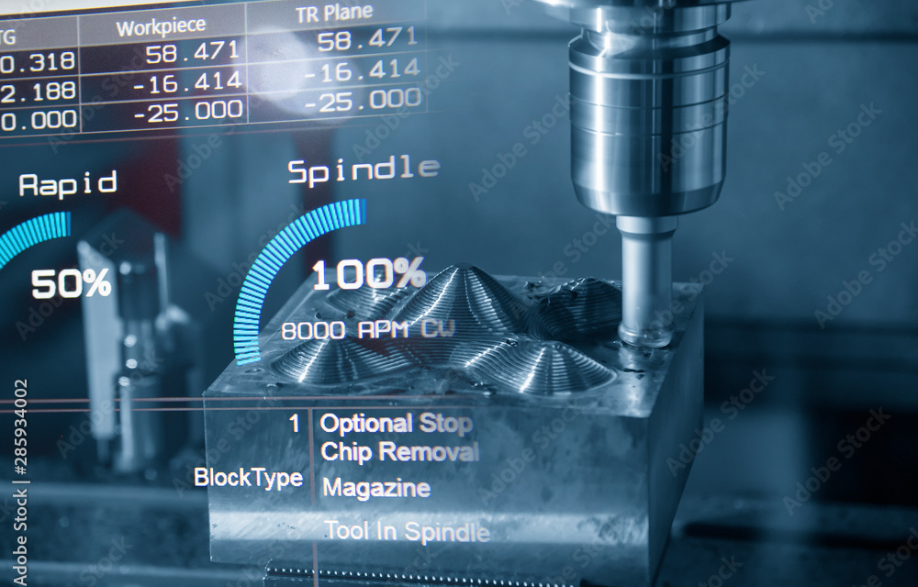

CNC milling, short for Computer Numerical Control milling, is a precision machining process that utilizes computerized controls to remove material from a workpiece. It involves using rotating cutting tools to gradually shape the desired part.

The process begins with a CAD (Computer-Aided Design) model, which is converted into instructions that guide the CNC machine. These instructions determine the tool paths, feed rates, and depths of cuts required to achieve the desired outcome.

During the milling operation, the workpiece is secured on a bed or fixture, while the cutting tool moves along multiple axes to remove excess material.

The advantages of custom CNC milling

The advantages of custom CNC milling are numerous. Firstly, the use of computerized controls ensures a high level of precision and accuracy, resulting in consistent and repeatable parts. This eliminates human errors and reduces the need for manual adjustments.

Additionally, CNC milling allows for complex shapes and intricate designs to be created with ease. The ability to program different tool paths and depths of cuts gives manufacturers the freedom to create highly detailed and customized parts.

Precision and accuracy in manufacturing

Precision and accuracy are crucial in the manufacturing industry, as they directly impact the quality of the final product. CNC milling plays a significant role in achieving these goals.

With CNC milling, manufacturers can consistently produce parts with tight tolerances and exact specifications. The computerized controls ensure that every cut is made with precision, resulting in high-quality finished products.

Furthermore, because CNC milling is a highly automated process, it reduces the risk of human error. Manual adjustments are minimized, leading to greater consistency and repeatability in production.

Customization options for unique designs and parts

Custom CNC milling offers a wide range of customization options, making it ideal for creating unique designs and parts. The ability to program different tool paths and depths of cuts allows manufacturers to bring any design concept to life.

Whether it’s intricate patterns, complex shapes, or custom prototypes, CNC milling can handle it all with ease. The computerized controls ensure that every cut is executed accurately, resulting in precise and detailed finished products.

This level of customization is particularly valuable in industries such as aerospace, automotive, and medical, where the demand for specialized components is high. CNC milling enables manufacturers to meet these demands by producing highly detailed and customized parts that fit the specific requirements of each industry.

Increased efficiency and productivity

Along with precision and customization, CNC milling also brings increased efficiency and productivity to the manufacturing process. The computerized controls allow for faster setup times, as the machine can be programmed to perform multiple operations without manual intervention.

This automation reduces production time, allowing manufacturers to meet tight deadlines and increase overall productivity. Additionally, CNC milling machines can run continuously, minimizing idle time and maximizing output.

Faster production times with CNC milling

Faster production times are a key advantage of CNC milling. With traditional manual machining, the process can be time-consuming and labor-intensive. However, CNC milling streamlines the production process by automating tasks and reducing the need for manual intervention.

By programming the machine, manufacturers can set up multiple operations to be performed sequentially or simultaneously, significantly reducing production time. This means that large quantities of parts can be produced in a shorter period, resulting in faster turnaround times for customers.

Conclusion of Custom CNC Milling Services

In conclusion, CNC milling offers numerous benefits to manufacturers in various industries. The ability to create highly customized parts tailored to specific requirements enhances the value and flexibility of the products.

Moreover, the increased efficiency and productivity resulting from automated controls allow manufacturers to meet tight deadlines and maximize output. Lastly, the faster production times offered by CNC milling enable quick turnaround times for customers, ensuring satisfaction and improved business success. Overall, utilizing CNC milling technology is a crucial factor in staying competitive in today’s manufacturing landscape.