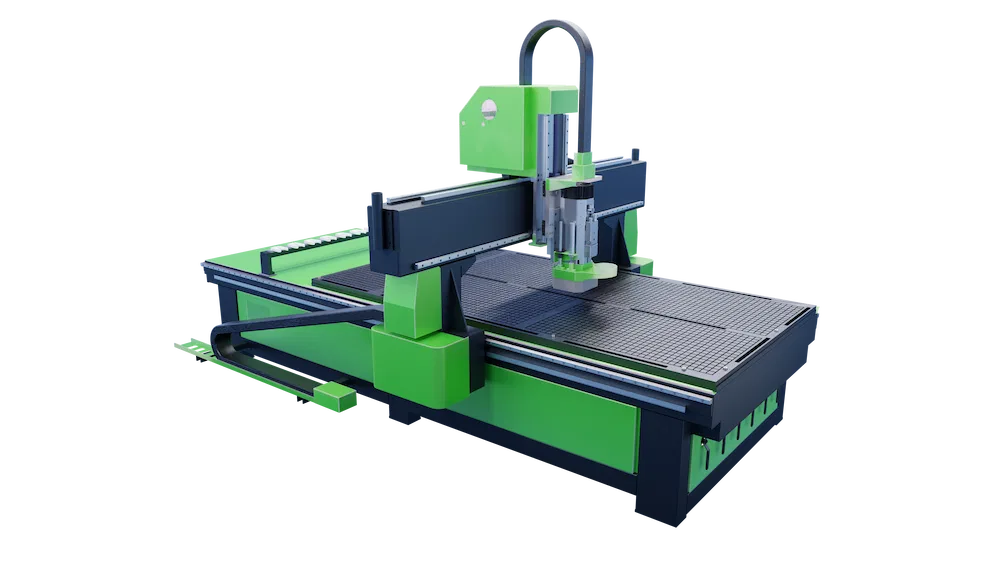

Custom CNC manufacturing services offerings are critical for industries desiring tremendous and precise parts. CNC (Computer Numerical Control) machines play a significant role in contemporary production, from aerospace to scientific devices. Let’s find out the top 10 benefits of Precision CNC machining solutions and how they transform precision production. Also, include who the top CNC Machining Services provider is.

Top 10 Benefits of CNC Machining Services for Precision Manufacturing

Incredible Precision

CNC machines are noticeably unique. They comply with specific designs and create components with tight tolerances. For instance, precision guarantees clean reduction and regular overall performance when producing ultra-large-length wire saw components. This stage of accuracy is almost impossible with manual machining.

Speed and Efficiency

CNC machines are fast. They can run 24/7 without breaks, making manufacturing quicker and more environmentally friendly. For industries, massive wire saws, quicker production, decreased costs, and faster challenge final touch.

Consistency and Reliability

Every element produced by a CNC machine is identical to the original layout. This consistency is ideal for packages where even a tiny flaw can cause massive troubles, like in the wire saw era. With CNC milling and turning services, manufacturers can rely on uniform quality.

Cost-Effective Production

Though CNC machines require upfront funding, they save money in the long run. They lessen cloth waste, decrease errors, and cut down labor costs. These savings may be sizeable for corporations specializing in large wire saws over time.

Supports Complex Designs

CNC machines can manage noticeably unique and complicated designs. Whether it’s problematic grooves or unique shapes, these machines make it feasible. This advantage is crucial for industries needing custom components like ultra-massive length wire saw structures with superior capabilities.

Compatible with Many Materials

CNC machines can work with metals, plastics, composites, and more. This flexibility allows producers to create long-lasting, specialized additives for wire saws that are tailor-made to particular wishes.

Reduces Human Error

Mistakes are common in guide machining. However, CNC machines comply with pre-programmed commands, leaving little room for errors. This ensures first-rate manufacturing, critical for precision gear like wire saws.

Scalability Made Easy

High-accuracy machining providers make scaling up manufacturing easy. Whether you want one component or one thousand, the technique is easy and green. For industries generating big wire saws, this scalability helps both small orders and mass manufacturing.

Improved Safety

Workers don’t want to stand near sharp gear or transfer parts with CNC machines. The computerized process keeps operators safe, a massive plus in manufacturing environments with big, effective devices like wire saws.

Faster Prototyping

Prototyping and production machining are perfect for creating prototypes. They allow manufacturers to test designs quickly and make improvements if needed. For large wire saw structures, this indicates quicker innovation and quicker time to market for brand-new models.

How CNC Machining Boosts the Wire Saw Industry

Ultra-massive-length wire saws require excessive precision and sturdiness. CNC machining is a game-changer in this area of interest. It guarantees every component meets specifications, plays perfectly, and lasts longer. These advantages helped wire producers stand out in an aggressive market.

Using CNC parts fabrication services, wire saw corporations can quickly lower production costs, improve element fine, and meet client demands. CNC generation is so valuable because of this precision, velocity, and fee financial savings aggregate.

Who Offers Top-Quality CNC Machining Services for Precision Manufacturing?

Regarding top-excellent CNC machining offerings for precision manufacturing, Junying CNC Machining Center stands proud. Known for its accuracy, reliability, and advanced generation, it delivers exquisite consequences throughout industries, including extremely large-size wire saw production.

Junying focuses on growing precise, long-lasting components using contemporary CNC machines. They work with various substances, from metals to plastics, ensuring each meets genuine specifications. Whether you want prototypes or large production runs, Junying handles everything with performance and care.

Their commitment to excellence is subsidized through certifications like ISO 9001, which ensures strict quality control. Customers agree with Junying for their rapid turnaround times, consistent consequences, and competitive pricing.

Frequently Asked Questions

What is CNC machining, and why is it critical?

CNC machining uses laptop-controlled gear to make components with excessive precision. It’s important because it guarantees constant quality and rapid production, which is crucial in industries like wire saw manufacturing.

Can CNC machines handle huge components for wire saws?

Yes, CNC machines can handle both small and large parts. They are perfect for growing components for extremely large-size wire saws with actual dimensions.

Is CNC machining cost-effective for small corporations?

Absolutely. While the preliminary funding is probably excessive, CNC machining reduces mistakes and waste, making it a cost-effective desire in the long run.

Final Thoughts

CNC machining offerings are a must-have for precision manufacturing. The benefits are plain: From slicing prices to improving first-rate, CNC technology is revolutionizing how additives are made for the wire saw enterprise, specifically ultra-large wire saws.

Advanced machining technology solutions make crafting complex components or scale manufacturing possible. Embracing this era is the key to staying ahead in a fast-paced global production sector.