Technology is advancing fast, and 3D laser scanning is one of the most exciting innovations. It helps many industries improve accuracy, speed, and efficiency. Whether in construction, manufacturing, or heritage preservation, 3D laser scanning plays a key role. We’ll explore what 3D scanning technology is, its top applications, and its benefits. We will also discuss its accuracy, scanning time, and the types of objects it can scan.

What is 3-D Laser Scanning?

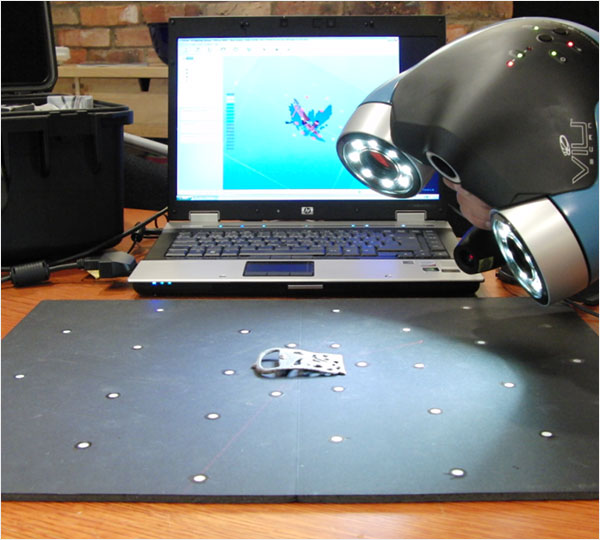

3-D laser scanning utilises laser bars to catch the shape and data of contraptions. The scanner gathers measurements focused on the floor of a thing and converts them into a virtual 3D version. This version is correct and can be utilised for analysis, design, and creation.

Top 7 Applications of 3-D Laser Scanning

Architecture and Construction

3D laser measurement systems are revolutionising the development industry. Architects and engineers use it to create specific construction fashions, discover structural problems, and plan renovations. It helps decrease mistakes, save charges, and enhance typical challenge performance. By scanning existing buildings, professionals can increase distinct blueprints for recuperation and redesign.

Manufacturing and Quality Control

Makers use 3D laser scanning to research parts and ensure they are the best. The technology detects any flaws in service by evaluating scanned objects with unique designs. This guarantees that each product meets high requirements.

Automotive and Aerospace Industry

Digital 3D modeling helps with layout, checkout, and maintenance in the car and aerospace industries. Engineers experiment with vehicles and aircraft to research their shape and improve performance. It also assists in reverse engineering, wherein antique or broken components are scanned and reproduced accurately.

Heritage and Archaeology

Preserving historical monuments and artefacts is less complicated with 3-D laser scanning. It creates digital copies of sculptures, buildings, and ancient gadgets. This permits experts to study and repair them without damaging the originals. Museums and researchers use the generation to report precious pieces and proportion them with the arena.

Medical and Healthcare

Reverse engineering services perform a key role in healthcare. It helps in growing custom prosthetics, dental implants, and orthopaedic devices. Doctors use it to experiment with sufferers’ bodies and expand remedies tailored to their desires. This technology improves clinical accuracy and affects personal comfort.

Oil, Gas, and Energy Industry

The oil and gasoline industry uses 3-D laser scanning for pipeline inspections and plant renovation. It allows for locating leaks, structural weaknesses, and system disasters. By scanning refineries and offshore systems, engineers can prevent highly-priced maintenance and ensure protection.

Film and Entertainment Industry

LiDAR scanning solutions are widely used in movies, video games, and virtual reality. It captures real-world environments and converts them into virtual models, enhancing visible effects and creating sensible animations. Many filmmakers use it to bring fictional worlds to life with lovely accuracy.

Benefits of Using 3-D Laser Scanning Services

Industrial 3D scanning offers many benefits. It improves accuracy, reduces human errors, and saves time. The technology quickly captures millions of record points, making it greener than traditional measuring strategies. It is likewise non-touch, which means it can test sensitive gadgets without harming them.

How Accurate is 3-D Laser Scanning?

3D laser scanning is shockingly exact, with accuracy down to millimetres or even microns. The genuine accuracy relies upon the scanner type and application. Industrial scanners in manufacturing and construction offer specific measurements that ensure ideal designs and fittings. This degree of accuracy enables excellent management and product improvement.

What Types of Objects Can Be Scanned with 3D Laser Scanning?

Precision metrology scanning can capture almost any item, large or small. It scans buildings, automobiles, equipment, and landscapes. It works for smaller objects like jewellery, clinical implants, and electronic elements. The technology is flexible and may experiment with intense and complex systems, making it beneficial across many industries.

How Long Does a 3-D Laser Scanning Process Take?

The time expected for 3D laser filtering depends on the size and complexity. A small object can take only a few minutes, even as scanning a massive building could take several hours or even days. Resolution, element stage, and environmental conditions can also affect the scanning length. However, 3-D laser scanning is faster and more excellent green compared to manual measuring techniques.

Top CNC Manufacturing Service in China

Junying is China’s leading CNC service provider with decades of experience. The industry offers OEM customers a one-stop service, such as CNC machining elements and prototypes. Junying operates hundreds of superior CNC machining machines, lathes, and service tools. Their centres encompass blasters and Ultra Sonic washing machines, ensuring high-quality manufacturing.

In addition to a superior system, Junying has a professional crew of skilled engineers, operators, and inspectors. They work collectively to bring customer designs to life with precision and efficiency. Junying guarantees top-notch CNC machining offerings tailor-made to patron needs for small or large-scale projects.

Junying is a dependent name for CNC manufacturing offerings in China. With superior technology and a professional crew, they offer dependable solutions for various industries. Whether you need CNC machining elements or prototypes, Junying’s one-stop carrier ensures top-exceptional effects.