CNC machines, quick for computer numerical control machines, are powerful equipment in worldwide manufacturing. They use computer instructions to lessen, form, and create particular factors from metallic, timber, or plastic substances. With CNC machines, companies can produce complex components faster and more correctly. Let’s dive into CNC machining, the kinds to be had, their programs, and why they’re so beneficial.

What is a CNC Machine?

A CNC tool is a computer-controlled tool that follows specific instructions, known as codes, to perform unique moves. These machines can drill, reduce, mill, or engrave. They are famous because they work fast and repeatedly make genuine copies of the same element.

Imagine a robot arm that follows accurate instructions. CNC cutting tools are like that! They carry out duties that are difficult or take a long time to do by hand.

Types of CNC Machines

There are several styles of CNC machines, each with a specific function. Let’s examine some modern kinds and explain what each one does.

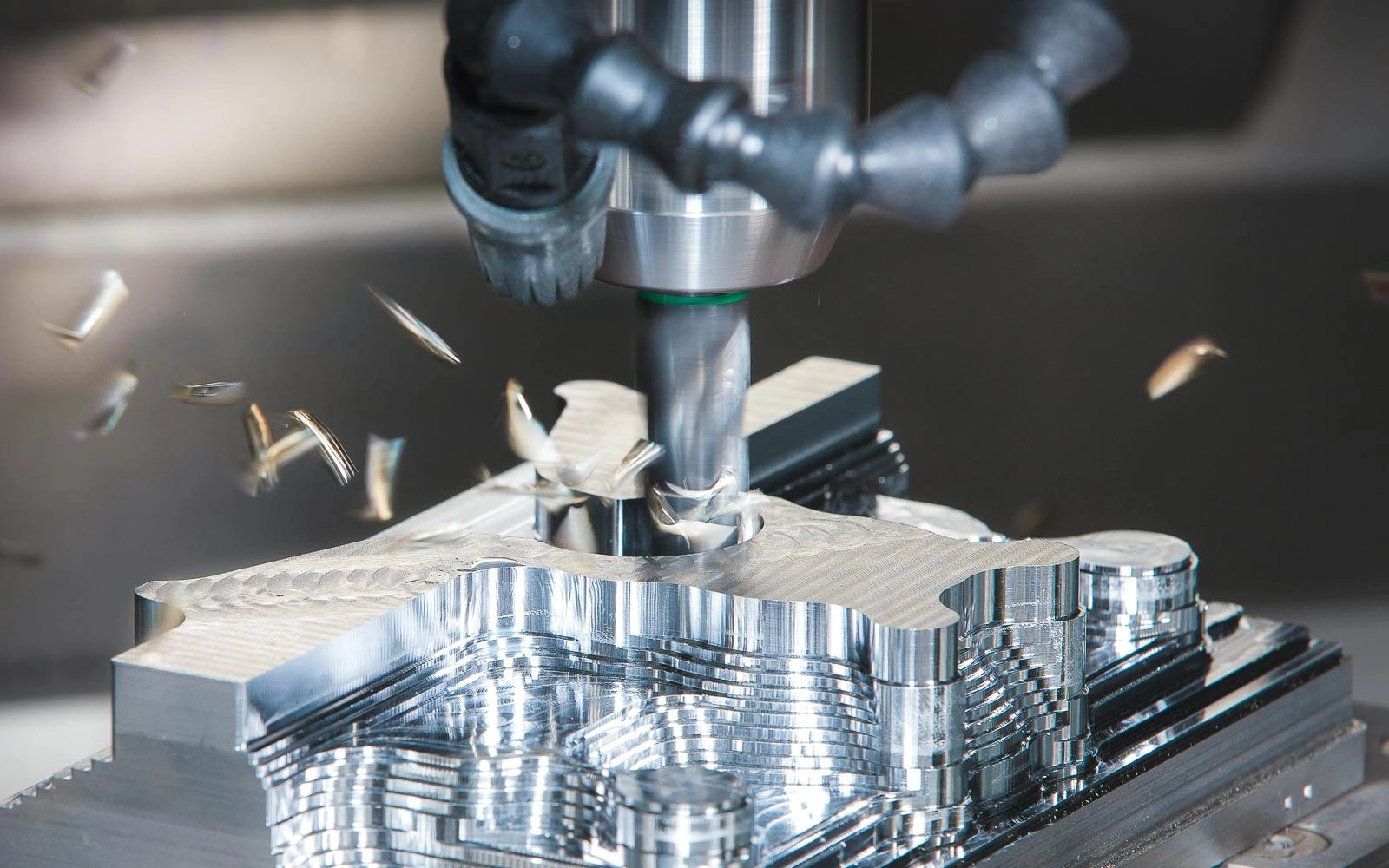

CNC Milling Machines

CNC milling machines are some of the most well-known CNC machines. They use a spinning device to cut and shape materials. The device moves up and down, left and right, to and fro, developing precise shapes. Milling machines are used to make cars, airplanes, and electronic factors.

CNC Lathes

CNC lathes rotate the material concurrently as a reducing tool shapes it. This approach is known as “turning.” Lathes are high-quality for making round or cylindrical elements, like screws, bolts, and pipes. They are very accurate and might produce clean surfaces.

CNC Plasma Cutters

A CNC plasma cutter uses a powerful jet of heat plasma to cut through steel. Plasma is a sizzling, electrically charged gas. Plasma cutters are fast and might reduce thick metallic quickly. They are frequently utilized in industries that paint with steel sheets.

CNC Laser Cutters

CNC laser cutters use an immoderate-powered laser beam to lessen or engrave substances like plasma cutters. These unique machines can lessen sensitive steel, wood, or glass designs. They are often applied in industries that require satisfactory records, like ring-making.

CNC Routers

CNC routers are like milling machines but are regularly used for softer materials like timber and plastic. These machines are well-known among woodworkers, fixture makers, and artists. A CNC router can create complex designs and shapes for innovative projects.

Applications of CNC Machines

CNC machines are used in many industries and may make a vast range of merchandise. Here are a few everyday packages:

- Automotive Industry: CNC machines manufacture gears, brakes, and engine parts. They ensure that every piece is identical, which is essential for protection.

- Aerospace Industry: Airplanes and rockets require noticeably particular parts. CNC machines help create elements that fit perfectly and can withstand intense situations.

- Electronics Industry: Small elements, like circuit boards and connectors, require exact measurements. CNC machines easily create these tiny, complicated parts.

- Furniture and Woodworking: CNC routers carve out shapes in wood and make furnishings components. With a CNC system, woodworkers can create targeted designs.

- Medical Field: CNC machines make scientific equipment, such as implants and surgical equipment. These elements should be accurate and perfectly fit the human frame.

Advantages of CNC Machines

CNC machines offer numerous benefits that make them treasured in cutting-edge manufacturing. Here are a number of their essential blessings:

- Precision: CNC machines comply with genuine instructions, making every component accurate. This precision is essential for industries like aerospace and clinical fields, wherein even small mistakes can cause significant issues.

- Speed: CNC machines work a good deal faster than people. They can quickly reduce, form, and end elements, meaning merchandise may be made faster.

- Consistency: CNC machines produce elements that can be nearly the same each time. This consistency is critical, especially for groups that want brilliant components.

- Efficiency: CNC machines can work continuously without getting tired. This makes them green for long manufacturing runs.

- Safety: CNC machines keep operators safe. The computer controls the machine, so employees don’t have to be near sharp or warm gear.

Disadvantages of CNC Machines

While CNC machines are splendid, they do have some downsides. Here are a few:

- Costly Setup: CNC machines are expensive to shop for and maintain. The software program and schooling can also be added to the fee.

- Requires Skilled Operators: Although the gadget is PC-controlled, skilled operators must set it up and display it.

- Programming Time: Each component wishes to use a particular software, which can take time to write. Mistakes in the code can cause errors in the part.

Which is the excellent CNC Machining Service provider?

When finding a first-rate CNC machining issuer, Junying CNC Machining Center stands out due to its substantial desire. They offer unique and dependable CNC machining services tailor-made to satisfy diverse enterprise needs. With advanced equipment and skilled technicians, Junying guarantees exquisite effects for every project. Their services are first-rate for those searching for decorating production performance and merchandise. Junying’s willpower to patron pride, short turnaround instances, and competitive pricing make it the circulate-to company for all your CNC machining or Industrial automation dreams.

FAQs About CNC Machines

Can CNC machines paint with any fabric?

CNC machines can paint with various materials, such as steel, wood, plastic, or glass. The kind of device and the material it can handle determine which materials it can work with.

Are CNC machines only utilized in huge factories?

No, CNC machines are utilized in both big and small workshops. Many small organizations and artists use CNC routers for woodworking and engraving.

In Wrap Up the Content

CNC machines have converted how merchandise is made. From automobile elements to earrings, they produce unique and outstanding gadgets. We can see why they’re critical in CNC manufacturing by providing information on the forms of CNC machines, their applications, and their advantages. With their velocity, accuracy, and potential to work with many substances, CNC machines continue to shape industries worldwide. Whether in a massive manufacturing facility or a small workshop, CNC generation has become vital in modern-day production.