In the machining industry, “precision” is a key metric for evaluating the quality and capabilities of machining services. For many manufacturing companies and engineers, precision machining is not just a requirement for improved product quality but a crucial element for ensuring product performance, durability, and safety. So, why is precision machining so important? In this blog, we’ll delve into the role of accuracy in machining and the key factors to consider when selecting a machining service provider.

What is Precision Machining?

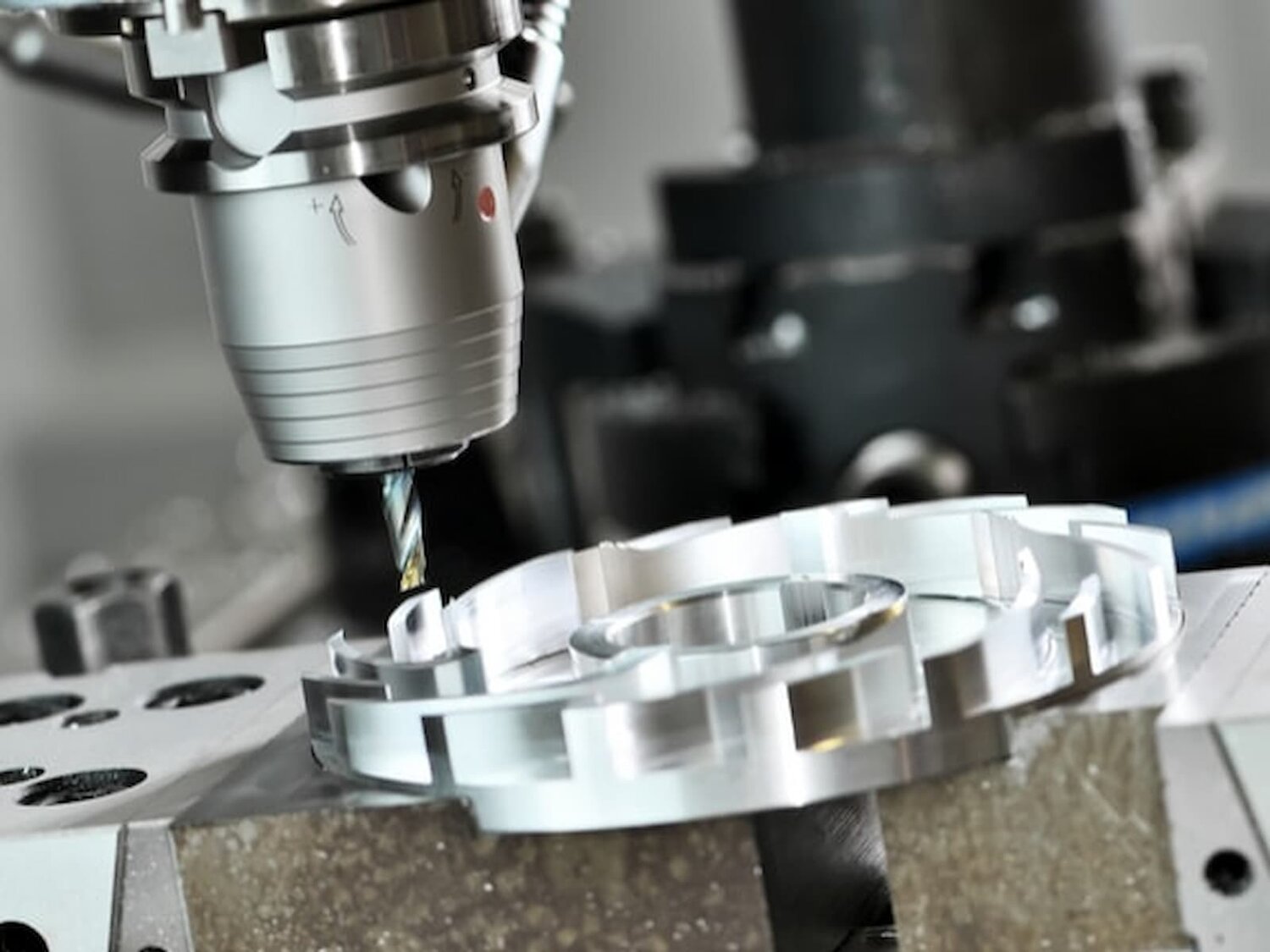

Precision machining refers to the use of advanced equipment like CNC machines to perform high-accuracy cutting, turning, milling, and other operations on metal or other materials to produce parts with tight tolerances. Unlike conventional machining, precision machining typically achieves tolerances within the micron range, ensuring that product dimensions and shapes are highly consistent.

Precision machining is essential for producing parts used in:

Aerospace components

Medical devices and instruments

Automotive industry key parts

Electronic product microcomponents

Why is Precision Machining Important?

Improving Product Performance

In industries like aerospace and healthcare, product performance is critical. A slight error in a precision part could directly impact the efficiency and safety of the equipment. Precision machining ensures that part surface finishes, dimensions, and shapes are perfectly aligned, optimizing product performance. For example, in engine manufacturing, precision machining reduces friction between parts, enhancing fuel efficiency.

Ensuring Product Consistency

Consistency is crucial in mass production. Even small deviations can affect product functionality and increase the costs of repair or replacement. Precision machining, with its highly automated control systems, guarantees consistent dimensions across production batches, minimizing human errors and delivering uniform quality.

Reducing Material Waste

Precision machining not only improves product quality but also minimizes material waste. The highly accurate cutting and shaping processes maximize material utilization, which is especially important when working with expensive materials like titanium alloys or stainless steel, helping to reduce costs.

Enhancing Product Durability

Precision machining improves the surface finish and dimensional accuracy of parts, reducing friction and wear during operation, which in turn increases product lifespan. This is critical for machinery and equipment that must operate continuously over long periods. For instance, automotive parts processed with precision machining not only improve performance but also reduce wear and tear, leading to fewer breakdowns.

Factors Affecting Precision Machining

Achieving high precision in machining requires careful consideration of several factors.

Machine Precision and Stability

High-precision CNC machines form the foundation of precision machining. The better the machine’s performance, the higher the achievable accuracy. Machine stability, especially during extended operations, is also critical. We use CNC machines with high rigidity and stability to maintain consistent precision during continuous machining.

Quality of Cutting Tools

The choice of cutting tools is equally important in precision machining. High-quality tools ensure efficient cutting, reducing vibration and wear during the process, thus improving machining accuracy. We rigorously select tool materials and perform regular maintenance to ensure they are always in optimal condition.

Process Optimization

Crafting the right machining process based on part shape and material properties is key to precision machining. For complex parts, we use multi-axis machining technologies to improve efficiency and precision. Additionally, appropriate cutting parameters (such as cutting speed and feed rate) are crucial for achieving the desired quality.

How to Choose a Precision Machining Service Provider?

When looking for a machining service provider, precision is a critical consideration. Here are some key points to keep in mind when selecting a precision machining partner:

Advanced Equipment: Ensure the provider has high-precision CNC machines and modern inspection equipment.

Experience: A team with extensive machining experience can offer the best solutions tailored to different needs.

Strict Quality Control: Providers should have thorough quality control processes, including dimensional checks and surface finish tests.

Customization Capabilities: The ability to offer personalized machining services based on specific client requirements.

Conclusion

Precision machining is increasingly important in modern industries, as it not only influences product performance and consistency but also impacts production costs and product lifespan. Choosing a machining service provider with advanced equipment, extensive experience, and stringent quality control will give you a competitive edge in the market. If you have any precision machining needs, feel free to reach out to us. We are committed to delivering high-quality, efficient, and customized machining solutions.