In the world of precision manufacturing, creating high-quality components isn’t just about intricate designs or seamless machining. It’s also about ensuring durability, functionality, and a flawless finish. This is where the combination of CNC machining and nickel plating steps into the spotlight—a duo that transforms raw materials into masterpieces of engineering.

The Precision of CNC Machining

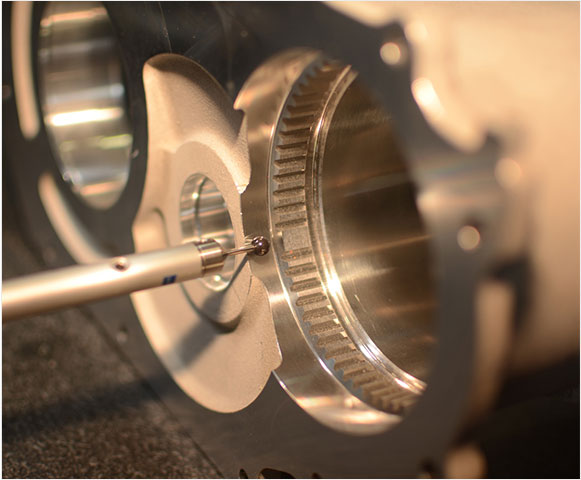

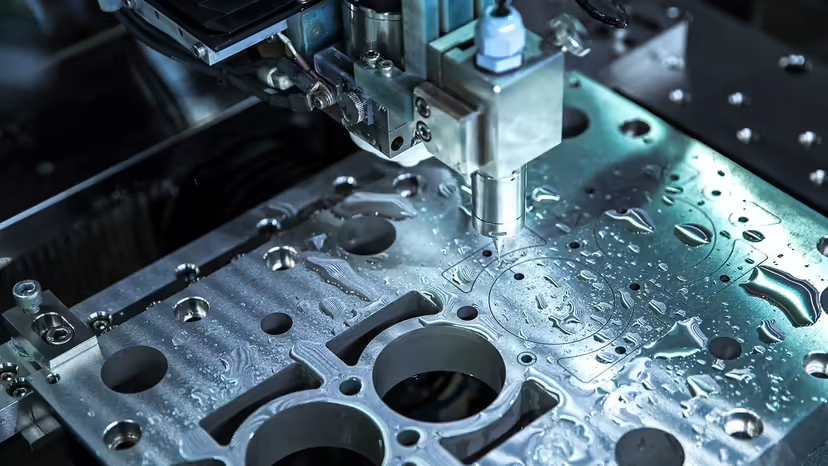

CNC (Computer Numerical Control) machining is the cornerstone of modern manufacturing, offering unparalleled accuracy and repeatability. It carves out intricate shapes from materials like aluminum, stainless steel, and brass with micrometer precision. Whether it’s an aerospace component or a delicate medical device, CNC machining ensures every curve, hole, and edge is perfectly crafted to meet stringent specifications.

But machining alone doesn’t always complete the story. Components must endure harsh environments, resist corrosion, and maintain their aesthetic appeal. That’s where nickel plating steps in as the ultimate finishing touch.

The Magic of Nickel Plating

Nickel plating isn’t just a shiny layer; it’s a powerhouse of protection and performance. This electrochemical process deposits a thin layer of nickel onto a machined surface, offering benefits that go far beyond appearance.

Corrosion Resistance

Nickel plating provides a robust barrier against oxidation and environmental damage, making it ideal for components exposed to moisture, chemicals, or extreme conditions.

Wear Resistance

The added hardness of nickel enhances the longevity of components, especially those subject to friction and repetitive use, such as gears or sliding mechanisms.

Improved Aesthetics

From a sleek, mirror-like finish to a matte, industrial look, nickel plating offers versatility in design, appealing to both functional and decorative needs.

Electrical Conductivity

For applications in electronics, a nickel layer ensures reliable conductivity and minimizes electrical resistance, critical for circuits and connectors.

The Perfect Synergy: CNC Machining Meets Nickel Plating

When combined, CNC machining and nickel plating elevate each other’s strengths. Imagine a meticulously machined part with complex geometries—perhaps a prototype for a cutting-edge robotics system. Without proper surface treatment, its lifespan and reliability might falter. Nickel plating ensures that the component isn’t just precise but also resilient, ready to withstand the test of time and use.

Types of Nickel Plating for Diverse Needs

The flexibility of nickel plating makes it suitable for a wide range of industries, thanks to its customizable techniques:

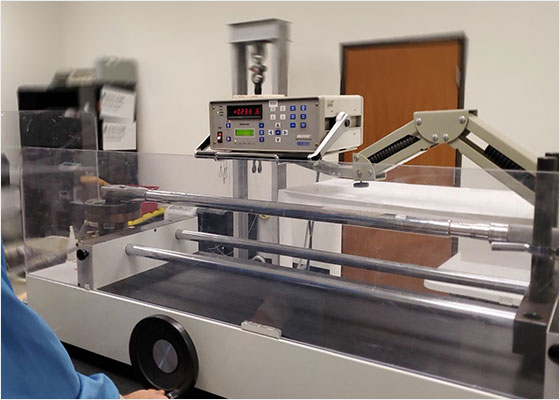

Electrolytic Nickel Plating : Best for parts requiring precise thickness control.

Electroless Nickel Plating : This chemical process provides uniform coating, even on complex shapes, and is especially valued for its enhanced wear and corrosion resistance.

Hard Nickel Plating : Perfect for industrial machinery, this type increases surface hardness dramatically, extending the lifespan of critical components.

Applications Across Industries

From aerospace to automotive, CNC machining and nickel plating shine in diverse sectors:

Aerospace : Ensuring lightweight components resist corrosion at high altitudes.

Medical Devices : Creating biocompatible, durable tools with precision finishes.

Electronics : Enhancing the durability and conductivity of connectors and switches.

Luxury Goods : Adding a touch of elegance to watches, jewelry, and high-end appliances.

Key Considerations for Success

The success of CNC machining and nickel plating lies in attention to detail:

- Material Compatibility : Not all metals are equally receptive to nickel plating. Pre-treatment steps like polishing or acid etching may be required.

- Thickness Control : For tight tolerances, the plating layer must be precisely calculated.

- Post-Plating Processes : Additional treatments, like passivation or coating, can further enhance performance.

A Finishing Touch for the Future

As industries demand greater precision, durability, and sustainability, the partnership between CNC machining and nickel plating will only grow stronger. Whether it’s a complex aerospace component or a simple electronic connector, this fusion ensures every piece is not just functional but also a work of art.

By investing in high-quality machining and plating processes, manufacturers are not just building products—they’re building trust, reliability, and excellence. After all, a great product isn’t just about how it’s made but also how it endures.