Manufacturing has changed a lot over the years. With advanced machines, industries can now produce high-precision parts faster and more efficiently. One of the most important innovations in modern manufacturing is 5-axis CNC machining. This technology allows companies to create complex designs with high accuracy. Many industries rely on this service to make high-quality parts for different applications.

What is a 5-Axis CNC Machine Service?

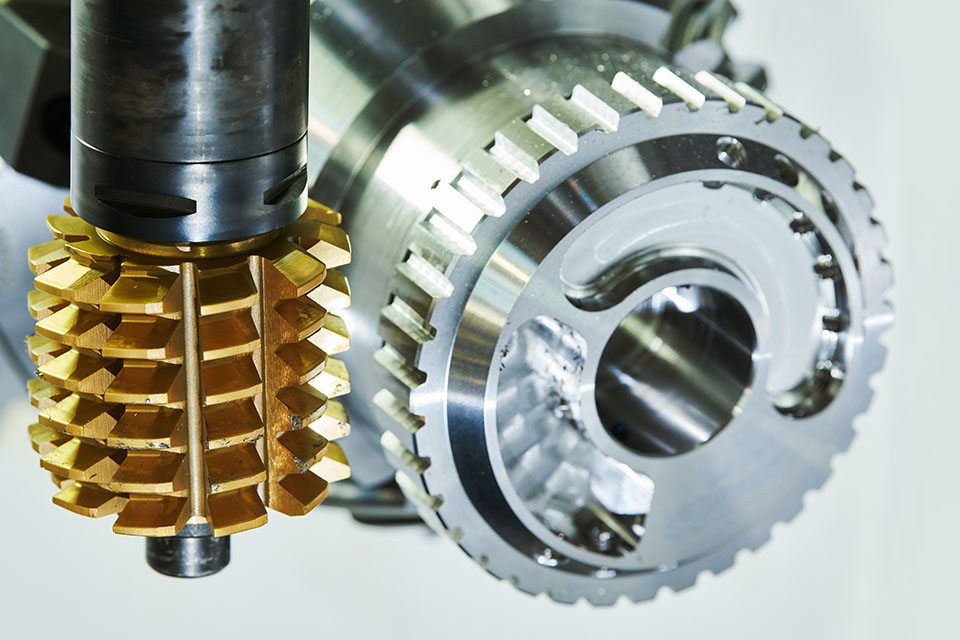

A 5-axis CNC system is a computer control device that moves in 5 instructions. Unlike conventional machines that paint, which work on 3(X, Y, and Z), a CNC milling service can also rotate around more excellent axes. This allows the tool to precisely and flexibly reduce, drill, and shape substances.

What Industries Use 5-Axis CNC Machining Services?

Many industries rely on 5-axis CNC machining for their manufacturing dreams. One of the primary industries is aerospace. Aircraft elements want to be lightweight but robust. The precision of multi-axis machining technology guarantees that components like turbine blades, engine factors, and structural components meet strict corporation standards.

Automobile companies also benefit from CNC machining. Car producers use this technology for technology components, transmission components, and custom car designs—the system’s high precision and speed help enhance its typical overall performance and protection.

Another corporation that relies upon this agency is clinical manufacturing. Medical gadgets and implants require high accuracy. CNC prototyping and production produce surgical gadgets, prosthetic limbs, and dental implants with perfect precision. This ensures that medical specialists can depend on terrific tools for affected individual care.

The robotics corporation also relies on this period. Robots want custom factors with complicated geometries. High-precision CNC parts can create those components sincerely, making it viable to make more significant, superior robotic systems.

The company also benefits from using large quantities of delivered plastic and steel portions—5-axis CNC molds with clean surfaces enhance the product’s appearance.

How Does 5-axis CNC Machining Differ from 3-axis Machining?

The crucial difference between 5-axis and 3-axis machining is the sort of motion. A 3-axis system moves along 3 hints: X (left to proper), Y (the front to once more), and Z (up and down). This limits its capability to create complex shapes.

Alternatively, a 5-axis device acts in the X, Y, and Z axes while rotating A and B). This allows the machine to cut at different angles without repositioning the workpiece. The result is faster production, higher accuracy, and the ability to create intricate designs.

With 3-axis machining, several setups are required to take advantage of complex cuts that allow you to boom manufacturing time and expenses.

How Much Does a 5-Axis CNC Machining Service Cost?

The charge of a Metal fabrication services company is based on several elements. One crucial detail is the complexity of the layout. If the details call for strict data and particular, it will take more to provide, increasing the rate.

Another problem is the material used. Different substances have unique machining charges. More complex substances, such as facet titanium, require specific gadgets and take longer to tool, making them extra luxurious.

The number of elements also influences the price. Large manufacturing runs typically have fewer units, while one-time custom elements are highly priced.

The provider region plays a role as well. Companies in the precise areas have one type of intricate work and walking costs. If you are looking for plenty less high-priced and reliable industry, Junying in China is a fantastic preference. They provide splendid machining services at a much less expensive.

Do I Choose the Right 5-Axis CNC Machining Service Provider?

Choosing the proper provider is critical for buying superb results. One of the number one subjects to don’t forget is to revel in. Look for a company that has been in the organization for a long term and has enjoyed different obligations.

Another vital detail is the technical and device. The provider should use superior machines to ensure precision and performance. Outdated tools can also result in poor-quality parts.

Customer opinions can also help in making a decision. Check online critiques and testimonials to see what previous customers say about the industry’s offerings. A provider with excellent feedback is much more likely to provide exceptional work.

The company’s company’s rate should also be considered. While you don’t need to compromise on super, you should observe prices to ensure you get a sincere deal.

If you’re looking for a trusted employer, Junying in China is the best choice. They offer top-quality CNC prototyping and production and have a robust reputation for precision and reliability.

Where to Go for Advanced Details on 5-Axis CNC Machines?

Various assets must be had to check more about 5-axis CNC machines. You can find reliable websites that provide current facts on technology and services. Many schools and online courses offer education in CNC machining, helping you observe each essential and superior talent.

Trade shows and industry activities are also outstanding places to gain insights. You can see modern machines at those activities, meet specialists, and get expert recommendations.

Junying is an outstanding opportunity for expert guidance. It offers a wide range of information and services related to CNC machining. Whether you need help with a mission or want to examine it, its website has valuable statistics.