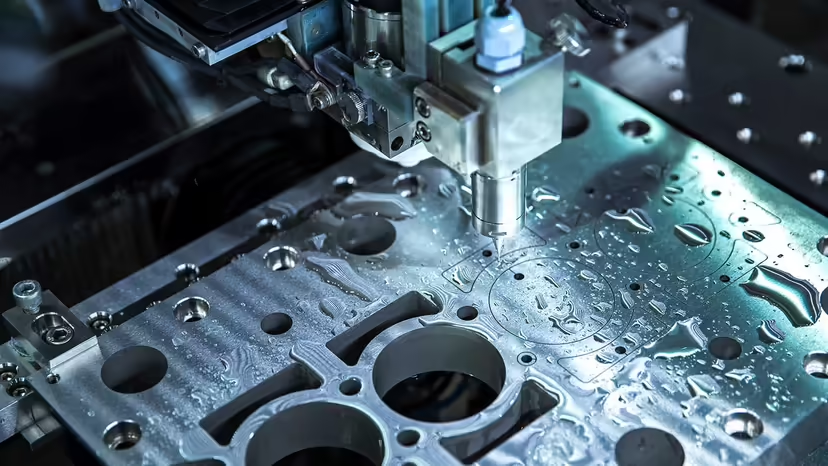

In the realm of modern manufacturing, the significance of Axis CNC machines is paramount. These machines, known for their precision and efficiency, have revolutionized the industry. By enabling automated control of machining tools with computer programming, they’ve brought about a new era of production.

The versatility of Axis CNC machines, capable of moving along multiple axes, has opened up possibilities for creating complex and intricate designs with ease and accuracy. This has not only enhanced productivity but also spurred innovation in manufacturing. Learn in detail what is a axis cnc machine?

What is a 5 axis cnc machine?

Axis cnc machines are PC-controlled gadgets that work along different axis focuses. The course of CNC machining includes eliminating material from a workpiece until the ideal shape is accomplished. These machines normally work along a XYZ plane, with the X-axis being upward, the Y-axis being even, and the Z-axis addressing profundity.

Types of axis cnc machines

CNC machines come in different sorts given the quantity of axis they have. The most well-known ones incorporate 2-axis, 3-Axis, 4-Axis, and 5-Axis CNC machines.

- 2-axis cnc machines: These machines work along the X and Y axis and are generally utilized for making various parts and items with exact precision.

- 3-Axis CNC Machines: These machines work along the X, Y, and Z axis, giving greater adaptability and command over the machining system.

- 4-Axis CNC Machines: notwithstanding the X, Y, and Z axis, these machines have An extra axis, which is considered axis or slant around the X axis.

- 5-axis cnc machines: These machines work along the X, Y, and Z axis and two out of the A, B, and C axis, offering significantly more prominent control and accuracy.

Components of an Axis CNC Machine

- Principal Casing or Bed

The principal outline, otherwise called the bed, is the foundation of the CNC machine. It gives security and decreases vibrations during activities, guaranteeing accuracy and precision.

- axis (X, Y, Z)

The X, Y, and Z axis are the essential headings where the CNC machine can move. The X-axis addresses level development, the Y-axis vertical development, and the Z-axis profundity.

- Spindle

The shaft holds and axes the cutting device. Its speed and power essentially impact the machine’s presentation and the nature of the completed item.

- Control Board

The control board is the CNC machine’s mind. It deciphers directions from the PC and controls the machine’s developments and activities.

- Motors and Drive Systems

Engines and drive frameworks convert electrical energy into mechanical energy, driving the machine’s developments along the axis.

- Tooling and Workholding Gadgets

Tooling alludes to the cutting apparatuses utilized in the machine while work holding gadgets secure the workpiece during activities.

Working Principles

- How Axis CNC Machines Interpret Instructions

CNC machines decipher guidelines through a cycle called PC Helped Assembling (CAM). The CAM programming changes over plans into a progression of orders, which the control board deciphers and executes.

- Development Along Various axis

Development along the axis is constrained by the engines and drive frameworks. The control board coordinates these developments in light of the deciphered directions.

- Role of Computer Programming and Software

PC programming and programming plays a vital part in CNC machining. They empower the planning and execution of complicated tasks, improving the machine’s abilities.

Applications of Axis CNC Machines

- Manufacturing: CNC machines are broadly utilized in assembling because of their accuracy, proficiency, and capacity to create complex shapes.

- Prototyping: CNC machines are great for prototyping, taking into consideration the fast and practical creation of model parts.

- Metalworking: In metalworking, CNC machines give exact and predictable outcomes, making them vital in enterprises like cars and aviation.

- Woodworking: In carpentry, CNC machines empower complex plans and improve efficiency.

- 3D Printing: CNC machines are progressively being utilized in 3D printing, offering high accuracy and empowering the creation of mind-boggling shapes.

- Engraving and Carving: CNC machines succeed in etching and cutting assignments, giving high detail and accuracy.

Benefits of Axis CNC Machines

- Accuracy and Precision: CNC machines offer high accuracy and precision, guaranteeing reliable quality in created parts.

- Proficiency and Efficiency: With their robotized tasks, CNC machines essentially upgrade proficiency and efficiency.

- Flexibility: CNC machines are flexible, and fit for taking care of many materials and creating different shapes.

- Complex Shapes and Plans: CNC machines succeed in creating complex shapes and plans, growing the conceivable outcomes in assembling and planning.

- Automation and Repeatability: With their elevated degree of computerization, CNC machines can deliver indistinguishable parts again and again with an insignificant mistake, guaranteeing repeatability and consistency.

Last Words in what is a 5 axis cnc machine

Axis CNC machines have become key in the present assembling scene. Their capacity to perform complex errands with high accuracy has made them a foundation of present-day creation processes. As we move towards an inexorably robotized future, the job of these machines is set to turn out to be much more basic. They address the ideal mix of innovation and assembling, driving productivity, and cultivating development.