CNC milling is one of the most substantially used production techniques globally. It is a specific, efficient, and flexible technique for shaping materials into numerous additives. We can offer a cause in the back of what CNC milling is, how it works, its advantages and disadvantages clearly, and where it’s also used.

What is CNC Milling, and How Does It Work?

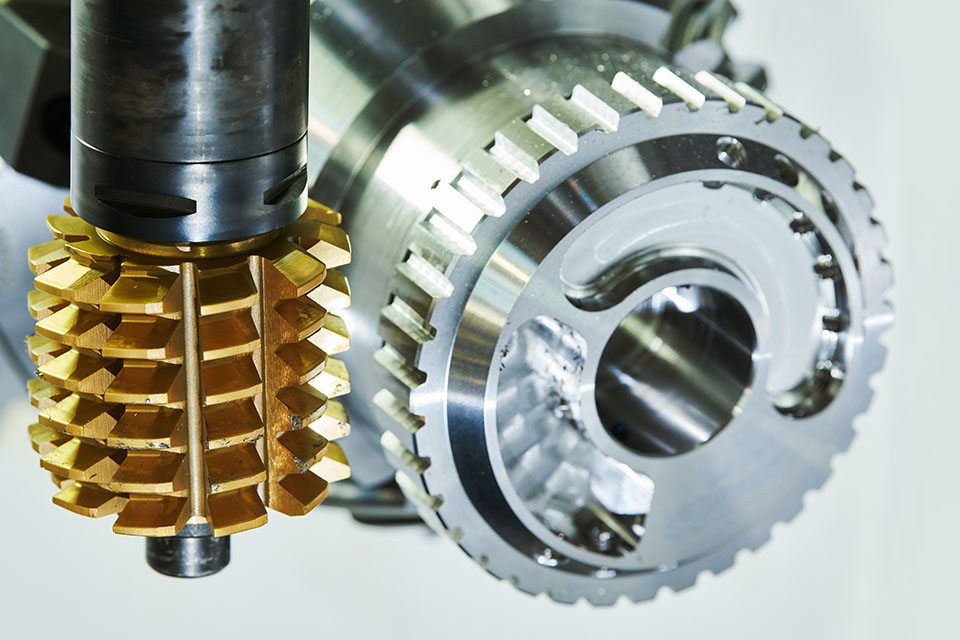

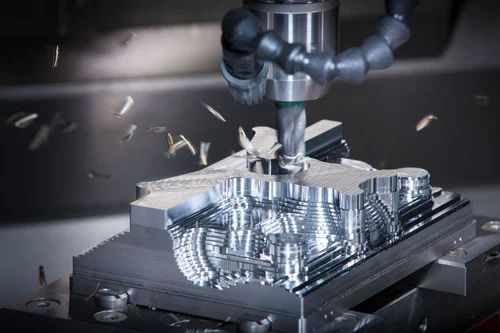

CNC milling is a computer-controlled method to reduce, shape, and drill substances into particular office work. CNC stands for Computer Numerical Control. A reducing device rotates while the material stays desk-bound or acts under the device in milling. The tool follows a programmed route to create the well-known shape.

The machine begins off evolved off evolved with a virtual format created using CAD (Computer-Aided Design) software utility software program. This layout is because it needs to be converted right into a CNC software application software software that publishes the device. Once this tool is loaded, the Computer Numerical Control machining eliminates layers of fabric from a stable block, developing the completed product.

CNC milling machine operations work with several materials: metals, plastics, and wood. It is famous within the vehicle, aerospace, and electronics industries due to its precision and capability to address complex designs.

What are the Advantages of CNC Milling?

Precision machining techniques have numerous benefits, making it a desired choice for producers. Here are its key advantages:

High Precision: CNC milling gives you fantastic accuracy. The computer-guided process guarantees that every factor meets specific specs, which is crucial for industries like aerospace and medical.

Repeatability: Once programmed, CNC milling machines can produce equal factors constantly. This makes it perfect for massive manufacturing runs.

Complex Designs: CNC milling can create complicated shapes and functions that may be difficult to benefit with guide machining. It permits multi-axis moves, bearing in mind superior designs.

Efficiency: The automation of CNC milling reduces production time. The machines can function continuously, speeding up the manufacturing manner.

Versatility: CNC milling works with a vast type of substances. Whether you want aluminum, steel, plastic, or perhaps wood, CNC milling can manage it.

Safety: Operators no longer want to be close to the decreasing gadget sooner or later in operation. This reduces the risk of accidents.

Reduced Waste: CNC milling minimizes material waste by precisely reducing quality, which is crucial. This makes it robust and environmentally excellent.

What are the Disadvantages of CNC Milling?

While CNC milling has many advantages, it doesn’t always have disadvantages. Here are a number of its risks:

High Initial Costs: Setting up CNC milling machines may be luxurious. The machines, software programs, and schooling rates can be significant for small groups.

Complex Programming: Creating CNC packages calls for information and facts. Mistakes in programming can bring about expensive errors.

Maintenance Requirements: CNC milling machines want everyday protection to ensure maximum green, ordinary, regularly occurring, and typical overall performance. Downtime for upkeep can disrupt manufacturing schedules.

Material Limitations: While CNC milling works with many materials, a few surprisingly tough or brittle materials may not be suitable.

Limited Customization During Operation: Once a software program application software is loaded, making on-the-fly modifications may be challenging in contrast to guide machining.

What are the milling machine applications?

CNC milling is used throughout several industries because of its precision and flexibility. Here are a few typical applications:

Automotive: CNC milling produces engine additives, gears, and excellent additives that require immoderate accuracy.

Aerospace: This employer relies on CNC milling for turbine blades, structural additives, and touchdown gadget components.

Electronics: CNC milling creates connectors, housings, and circuit forums for digital gadgets.

Medical: Surgical equipment, implants, and dental components are frequently made using CNC milling.

Consumer Goods: Items like custom rings, furnishings additives, and own family domestic gadgets gain from CNC milling’s precision.

Prototyping: CNC milling is proper for developing prototypes because it supplies complicated designs quickly.

CNC Milling with ‘Junying CNC Machining Center’

Junying CNC Machining Center is a relied-on call for top-notch CNC milling offerings. With a long time of enjoyment, Junying specializes in excessive-precision CNC machining for numerous industries. They offer one-save-you answers, which embody detailed manufacturing and prototyping.

Junying’s facilities have loads of advanced multi-axis milling processes and one-of-a-kind devices. Their crew of skilled engineers and operators ensures that each component meets the very best necessities. Whether you want a single prototype or mass manufacturing, Junying can supply it.

The company’s determination to be efficient and the purchaser’s pride gadgets them aside. They paint closely with customers to supply their designs to lifestyles. If you’re looking for reliable CNC machining services, Junying is the best choice.

The Bottom Line in this Content

CNC milling is an effective and flexible production method that mixes precision and everyday performance. While it has a few risks, its benefits outweigh them, making it a favored preference for many industries. From growing complex elements to generating large quantities with consistency, CNC milling maintains the destiny of manufacturing.

With experts like Junying CNC Machining Center, you may get proper access to top-super CNC milling parts production offerings that meet your desires. Explore CNC milling these days and notice how it could grow your obligations!