CNC Swiss machining is a cutting-edge method for making definite parts. It’s involved a ton in the aviation, clinical, and vehicle enterprises. It utilizes a PC to control the machine and make little, precise parts from various materials like metal, plastic, or extraordinary combinations.

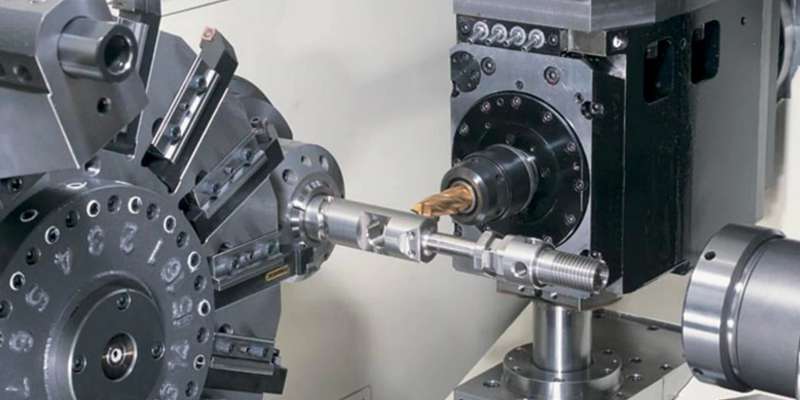

This is the secret: The CNC Swiss machine has an instrument that twists. A PC program controls this instrument. The machine takes care of a tube-shaped bar of material through an aide. The apparatus slices and shapes the material to the right size and shape. This course of cutting and taking care of simultaneously considers exceptionally precise estimations and definite plans.

A huge upside of CNC Swiss machining is that it can do many undertakings in one go. This implies one machine can take care of responsibilities like processing, boring, turning, and stringing. It doesn’t have to move the workpiece to various machines. This saves time and ensures everything is precise.

CNC Swiss machining is exceptionally exact. It estimates resistances in micrometres. This makes it ideal for occupations where exactness is vital. Likewise, it can make a ton of parts immediately with a similar quality. This settles on it a decent decision for making many parts without a moment’s delay.

Changing from old machining strategies to CNC Swiss machining has many advantages. It makes work more effective, eliminates stand-by times, and improves the eventual outcome. Additionally, CNC Swiss machines can make complex parts that would be hard to make with old techniques.

Why CNC Swiss Machining is Important in Manufacturing

Definite Designing: CNC Swiss machining is vital in making things since it’s extremely careful. It estimates resistances in micrometres. This ensures each part made is perfect. This is vital in enterprises like aviation, clinical, and vehicles.

Flexibility: A huge upside of CNC Swiss machining is that it can work with numerous materials. This incorporates metals, plastics, and extraordinary compounds. This allows producers to make various parts for various purposes. This addresses the issues of various enterprises.

Productivity and Setting Aside Cash: CNC Swiss machining is more proficient and sets aside cash contrasted with old machining strategies. It can do many errands in one go. This eliminates the time it takes to make things and decreases the requirement for individuals to step in. This brings down the expense of making things.

Making Many Parts: CNC Swiss machines can make many parts immediately. They keep a similar quality and don’t have to stop frequently. They can address the issues of making many parts without a moment’s delay while keeping everything definite. This ensures merchandise gets to advertise on time.

Development and Being Serious: Utilizing CNC Swiss machining assists with advancement and being cutthroat in the assembling area. Organizations that utilise this cutting-edge innovation can remain ahead by making complex parts with excellence and proficiency. This gives them an edge in their ventures.

Various types of CNC Swiss Machines

Traditional CNC Swiss Machines

These machines began present-day CNC Swiss machining. They have an aide bushing to help and consistent the workpiece during machining. They are perfect at exceptionally precise turning and processing undertakings. This makes them ideal for itemized parts in enterprises like clinical and gadgets.

Guide Bushing-Less CNC Swiss Machines

These machines work without an aide bushing. They utilize a sliding headstock that holds the workpiece. This allows them to machine longer and more slender parts with greater adaptability. This sort of Swiss machine is great for errands that need long machining lengths and less material waste.

Swiss-Type Turning Centers

These focuses blend CNC Swiss machining with conventional turning undertakings. They have a sliding headstock and an aide bushing. This allows them to do correct turning, processing, and penetrating across the board. These machines are adaptable and great for making complex parts with tight resilience in numerous enterprises.

Key Considerations for CNC Swiss Machining

CNC Swiss machining needs cautious preparation. Here are a few basic focuses to recall:

Picking Materials: Pick materials that function admirably with CNC Swiss machining. These can be metals, plastics, or extraordinary composites. Contemplate their hardness, heat conduction, and that they are so natural to the machine.

Planning Parts: When you plan parts, remember what CNC Swiss machines can do. Attempt to simplify your plans yet at the same time do what they need to do. They ought to likewise meet size resistances.

Selecting Tools and Fixtures: Pick the right cutting devices and installations for your requirements. Ensure the instruments are sharp, arranged accurately, and function admirably with the material you’re machining. This assists you with the exact outcomes.

Setting Up Machines and Programming: Plan your machine arrangements and programming great. This makes your tasks smoother and eliminates sat around idly. Use CAM programming to make effective device ways and improve machining processes.

Setting Resiliences and Controlling Quality: Set the resistances and quality principles for your parts. They ought to meet industry prerequisites and what your clients anticipate. Utilize severe quality control measures during machining to keep everything predictable and exact.

Overseeing Chips and Coolant: Handle chips well to prevent them from developing and hindering machining. Utilize the right coolant techniques to keep instruments greased up, dispose of intensity, and eliminate chips. This works on a superficial level of completion and makes instruments last longer.

Training Operators: Invest energy and cash in preparing administrators. This assists you with capitalizing on your CNC Swiss machining activities. Give administrators the information and abilities they need to fix issues, improve machining boundaries, and keep creation chugging along as expected.

Keeping up with Machines: Keep your CNC Swiss machines looking great to prevent them from separating and make them last longer. Do standard support assignments like evolving devices, greasing up, and aligning. This keeps machines working at their best.

Final Words

By pondering these focuses, you can make your CNC Swiss machining processes more productive, exact, and top caliber. With cautious preparation, doing things appropriately, and continuously attempting to improve, you can capitalize on CNC Swiss machining for your assembling needs.