Fused Deposition Modeling (FDM) is one of the most popular 3D printing technologies. It is widely used in industries like automotive, aerospace, and healthcare. This method builds objects through Layer-by-Layer Printing using melted thermoplastic material. Fused Deposition Modeling is known for its affordability and ease of use. Many hobbyists, engineers, and manufacturers prefer it for prototyping and small-batch production.

What is FDM (Fused Deposition Modeling) 3-D Printing?

Additive Manufacturing Technology is a 3d printing strategy that makes contraptions by ousting warmed plastic filaments through a nozzle. The nozzle acts along a preset route, depositing the material layer with precious resources. Once cooled, the plastic hardens into a business form. This method is proper for making solid, lightweight, and solid parts.

How Does FDM 3-D Printing Work?

3D Printing Materials follow a sincere technique. First, a 3-D version is designed using a CAD software program. The version is then sliced into layers using a reducing software application, which generates a route for the printer. The printer heats and extrudes the filament through a nozzle onto the print mattress. The nozzle follows the course outlined inside the software program software application, layer with the precious beneficial resource of the layer. As every layer cools, it bonds with the preceding one. The final item is quickly removed from the print bed because the printing gadget is complete.

Common Materials for FDM 3-D Printing

FDM 3-D printers use numerous thermoplastic substances. The most common ones encompass:

- PLA (Polylactic Acid): Simple to print, biodegradable, and reasonable for models and decorative devices.

- ABS (Acrylonitrile Butadiene Styrene): Solid, impact safe, and utilized for essential variables.

- PETG (Polyethylene Terephthalate Glycol): Intense, water-evidence, and excellent for mechanical parts.

- TPU (Thermoplastic Polyurethane): Adaptable and utilized for making elastic-like gadgets.

- Nylon: Solid, sturdy, and mainly utilized for business applications.

- PC (Polycarbonate): Intensity safe and extraordinarily complex, making it suitable for unnecessary energy applications.

The desire for garb is based upon the precise software software program used. PLA is first-rate for beginners, while ABS and Nylon are used for immoderate-energy additives.

What Are the Print Parameters for FDM 3D Printers?

Several parameters affect the brilliantness of Thermoplastic Filament. These include:

- Layer Height: Determines the print choice. Smaller layers produce finer data but take longer to print.

- Nozzle Temperature: Each cloth has a specific melting point. PLA prints at 180-220°C, even as ABS goals 220-250°C.

- Bed Temperature: Ensures proper adhesion. PLA calls for 50-60°C, while ABS desires 90-110°C.

- Print Speed: Faster speeds reduce printing time but may also affect accuracy.

- Infill Density: Determines the electricity of the detail. Higher infill makes components more potent, but it also uses more material.

- Cooling Fan: Helps save you from warping and improves print exceptional.

Adjusting these parameters successfully guarantees outstanding prints with minimal mistakes.

The Characteristics of FDM 3-D Printing

FDM 3-D printing has precise characteristics that make it popular. First, it’s cost-effective, making it high-quality for immediate prototyping. The method permits massive build volumes so that customers can print giant gadgets. FDM printers work with numerous thermoplastics, presenting flexibility in material preference. However, prints often have visible layer lines, which can also require post-processing for a smooth finish. Additionally, FDM printing is slower in assessing business techniques like SLS or SLA.

Difference Between Desktop and Industrial FDM Printers

Desktop and commercial FDM printers serve different desires. Desktop 3D Printers are much less pricey and suitable for non-public or small-scale use. They usually have smaller construct volumes and may not assist high-overall performance substances. Industrial FDM printers offer massive construct volumes, higher precision, and aid for engineering-grade plastics like ULTEM and PEEK. They are used in excessive-give-up applications in which power and durability are essential. While computing tool printers are excellent for beginners and prototyping, industrial machines are designed for big-scale production and outstanding production.

Best Practices for Printing with FDM

To achieve exceptional effects with Industrial 3D Printing, follow these top practices:

- Level the Print Bed: An uneven mattress causes negative adhesion and print screw-ups. Always test and alter the bed before printing.

- Use the Right Temperature: Set the nozzle and mattress temperatures consistent with the cloth used.

- Optimise Print Speed: Slower speeds decorate accuracy, whilst quicker speeds lessen printing time.

- Apply Adhesion Methods: To prevent warping, use a heated bed, glue stick, or PEI sheet.

- Calibrate the Printer: Regularly test the nozzle, stepper cars, and extruder to ensure a clean operation.

- Use Proper Infill and Supports: Higher infill makes prints more potent, whilst supports assist with overhangs.

- Store Filament Properly: Moisture impacts filament fantastically. Keep it in a dry, hermetic field.

Following the ones, pointers will help produce incredible prints with fewer issues.

Top CNC Manufacturing Service Provider in China

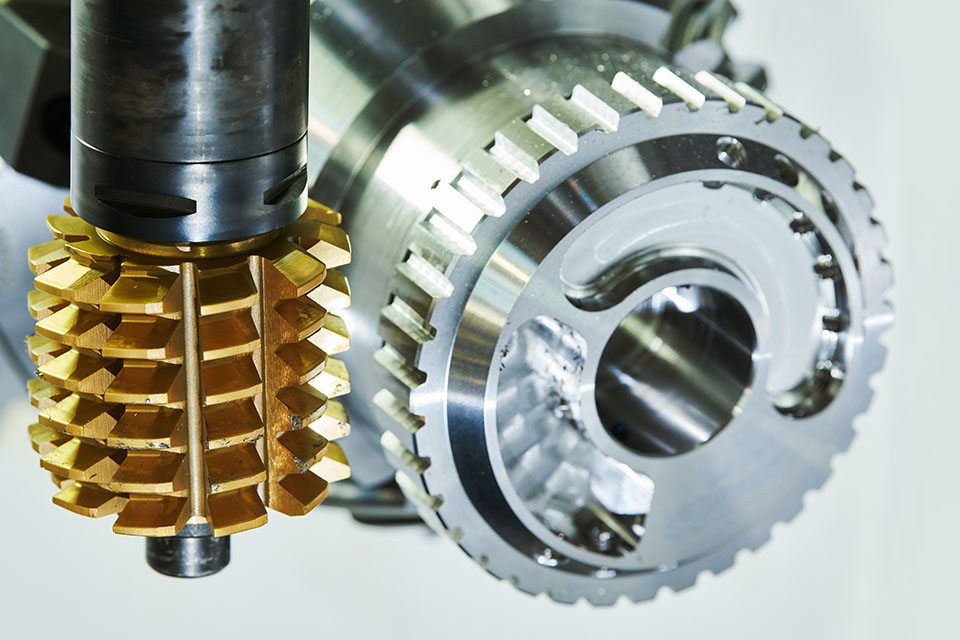

Junying is a trusted name in China for CNC production. Junying has a long experience in CNC manufacturing offerings and gives you one-save solutions for OEM clients. Their services consist of CNC machining additives and CNC machining prototypes. The agency operates hundreds of superior CNC machining, lathes, and different centres like blasters and ultrasonic washing machines. Junying CNC Machining Center no longer has a digital tool but a professional organisation of engineers, operators, and inspectors. Their knowledge guarantees that customers’ designs come into existence with precision and excessive brilliance.

Junying presents reliable services, advanced machines, and a skilled group for CNC manufacturing needs. Whether for prototyping or mass production, FDM printing remains a dependable choice for many applications.